Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.

Compared to the complete insulation layer produced by a professional wire and cable extruder, hand-wrapped tape is far inferior in performance.

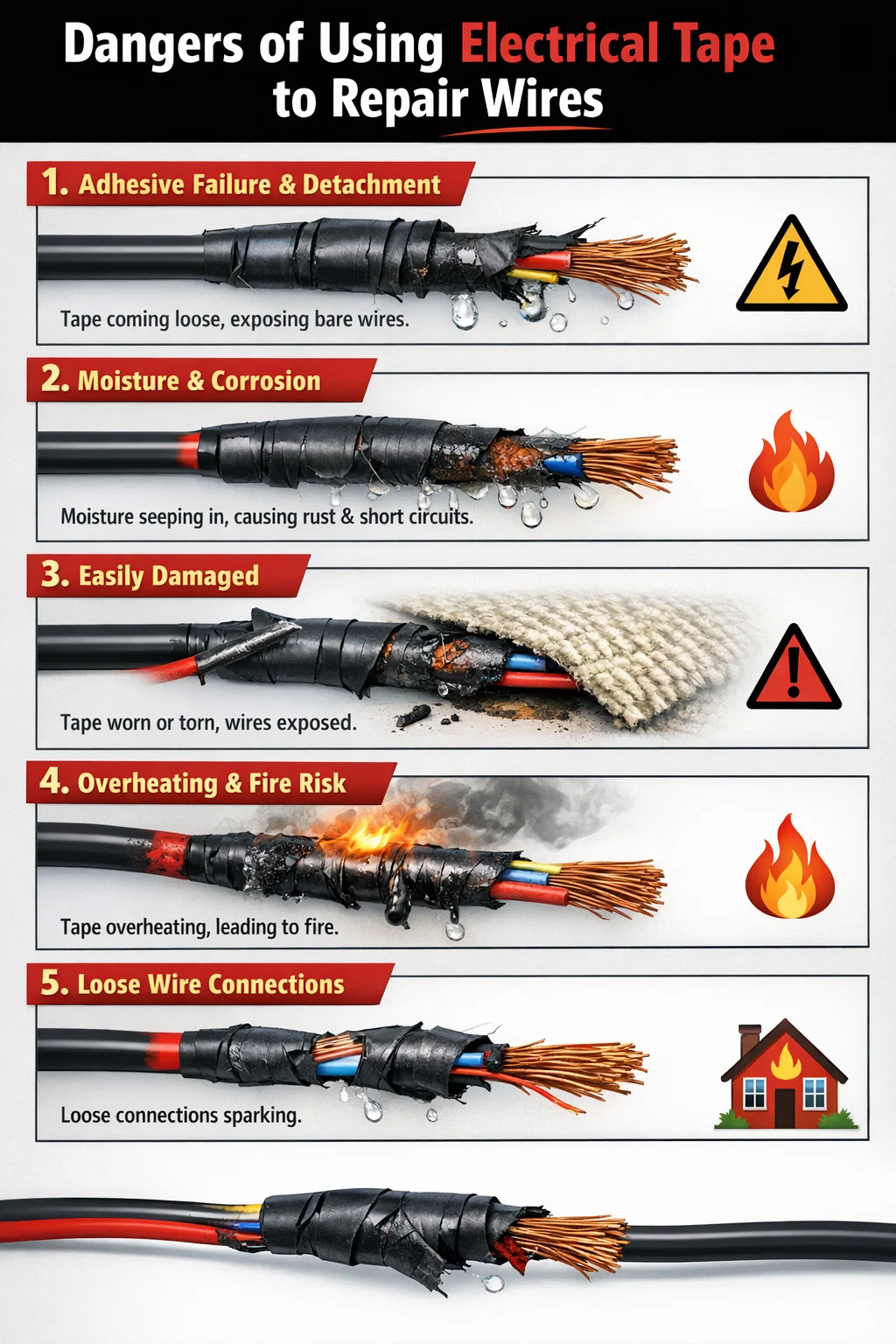

Here are some common risks associated with using electrical tape to repair wires:

1. Adhesive failure and detachment

Electrical tape is held in place by the adhesive on its back.

Temperature effects: Over time, changes in ambient temperature can cause the adhesive to dry out, harden, or become runny.

Consequences: Once the tape loses its adhesiveness, it will gradually peel off or detach completely. The exposed metal core will then be directly exposed to the air, which is very dangerous.

2. Inability to block moisture and humidity

The outer sheath of professional cables is tightly wrapped and sealed around the inner core during the wire and cable extruder manufacturing process.

Gap issues: No matter how tightly you wrap it, there will always be tiny gaps between the layers of tape.

Consequences: If the environment is humid, moisture will seep through the gaps, causing the metal wires to rust and corrode, or even cause a short circuit and fire.

3. Insufficient mechanical strength

The insulation layer of original wires is extruded under high pressure by a wire and cable extruder, giving it strong toughness and wear resistance.

Easily damaged: Electrical tape is thin and easily scratched by sharp objects or cracked under pressure from furniture.

Consequences: If you hide the repaired wire behind furniture or under a carpet, prolonged friction may cause the tape to fail, creating a safety hazard.

4. Risk of overheating and spontaneous combustion

When the wire carries high-power appliances, the metal core will heat up.

Uneven heat dissipation: Wrapping the wire with thick tape will affect heat dissipation.

Consequences: Low-quality electrical tape is not only not heat-resistant, but can even fuel a fire when exposed to electrical sparks. This is completely different from the professional flame-retardant materials used in wire and cable extruder manufacturing.

Many people twist two broken wires together and then wrap them with electrical tape, which is actually very unreliable.

Poor contact: Electrical tape does not have the strength to secure the metal wires. If pulled, the wire ends inside may become loose.

Consequences: Poor contact can cause a rapid increase in local temperature, which is a direct cause of many household electrical fires.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products