COMPONENTS

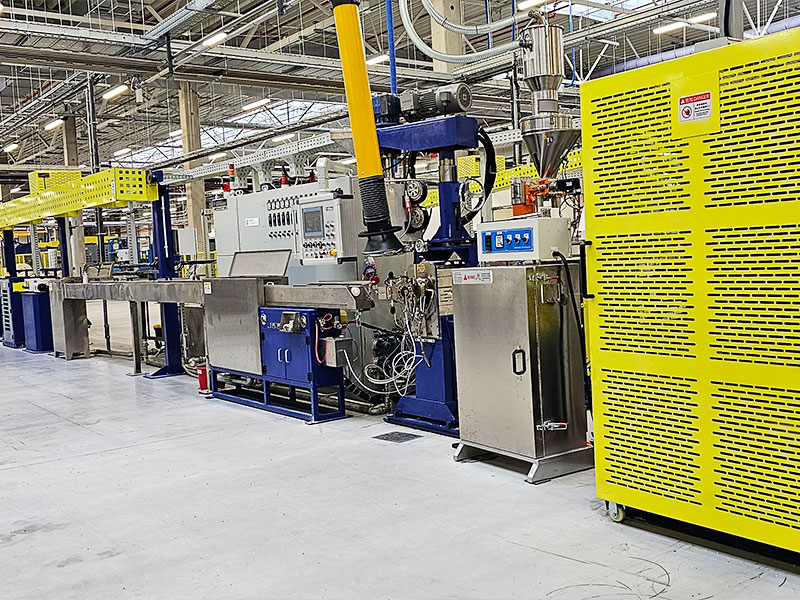

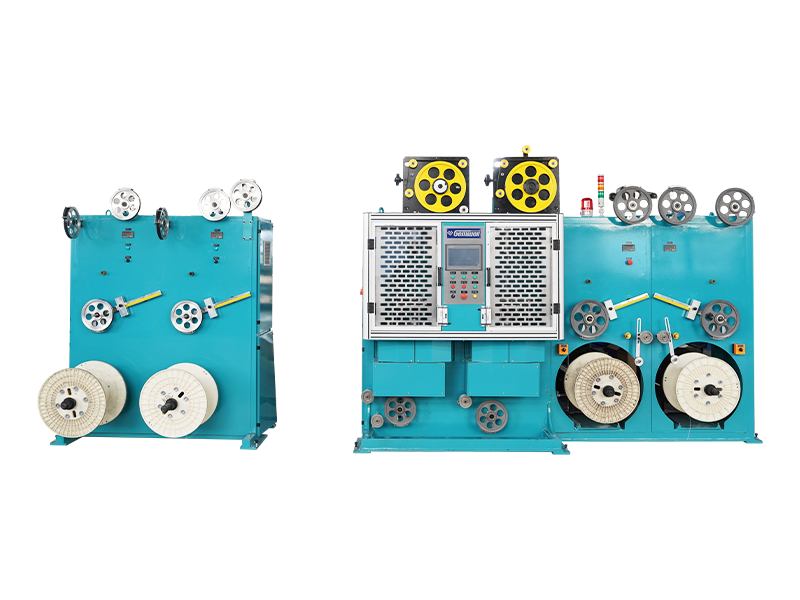

● Ø300 power pay-off stand 1 unit

● Tension stand 1 unit

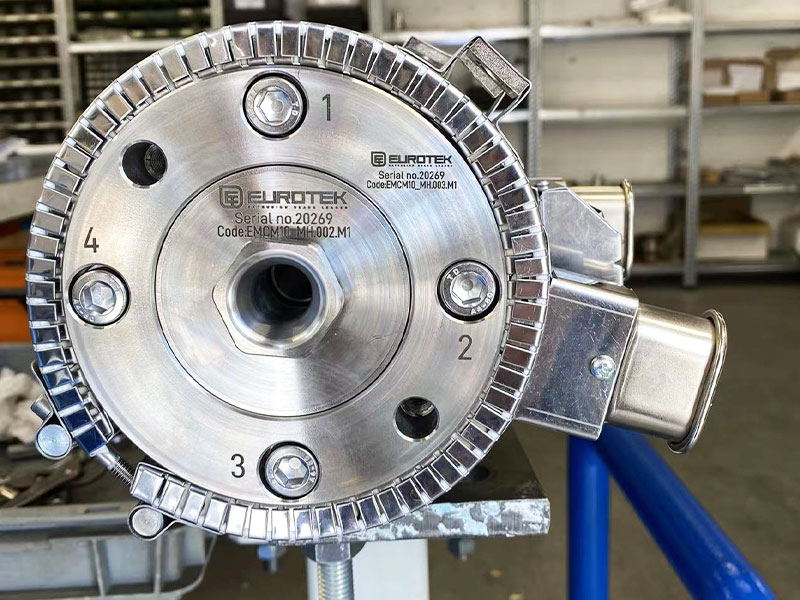

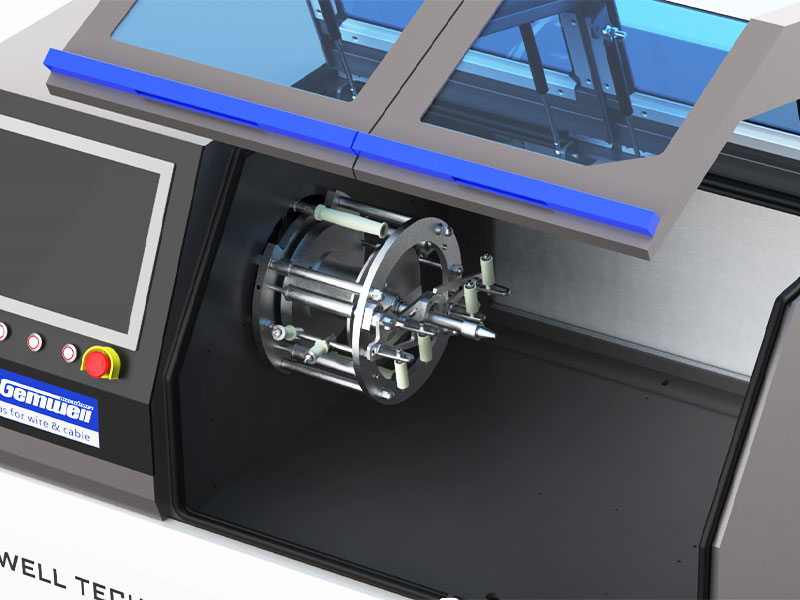

● Three-servo power wrapping machine taping head 1 1 unit

● Three-servo power wrapping machine taping head 2 1 unit

● Ø300 wheel type belt capstan 1 unit

● Spark Tester 1 unit

● Ø300 shaft type take-up machine 1 unit

● Control system 1 unit

TECHNICAL SPECIFICATIONS

| Structure type |

Three servo motion controller active type constant tension wrapping machine/power wrapping machine (Patent No. 202122403949.4A) |

| Suitable wire type |

Suitable for high-speed transmission lines, coaxial lines, control lines, special cables and other round wire winding and wrapping tape. |

| Applicable materials |

AL, MYLAR, COPPER FOIL, PTFE etc. |

| Applicable wire diameter |

Optimum range:Ø0.2-1.5mm |

| Product Specification |

Optimum range:Ø0.3-2.0mm |

| Maximum speed |

MAX2500RPM (no load), actual start-up speed is set according to the wire requirements |

| Wire speed range |

0.5-10m/min, the speed range is different according to the wire type. |

| Tape reel outer diameter |

Optimal range:Ø100*100 |

| Tape width |

1.5-15mm |

| Tape reel inner diameter |

25.4 |

| Wrapping pitch |

0.5-10mm, program setting |

| Tension range |

0.5N-30N/50g-3000g |

| Main motor power |

1.8KW servo motion motor |

| Taping power |

1.3KW servo motor |

| Wrapping tape tension |

0.4KW servo motor |

| Take-up power |

400 wheel belt type capstan, 0.4KW servo gear motor |

| Pay-off power |

0.4KW gear motor |

| Take-up power |

0.8KW servo motor |

| Winding displacement power |

0.4KW servo motion controller |

| Tape length |

300mm, without cutting the wire when changing reel |

| Tape inspection |

Automatic shutdown when the tape is about to be exhausted and broken. |

| Tape wrapping mould |

The inner mould of tape is fixed on the central conduit, the outer mould of the wire guide wheel is fixed on the tape storage tube. Both molds are extendable and movable. |

| Tape wrapping accuracy |

Pitch tolerance:± 1%, tension tolerance:± 1%. |

| Overlap rate |

0-80%, program setting |

| Formula management |

Digital production, tension, outer diameter, pitch, S/Z, row distance, air pressure and other data can be stored into the PLC. |

| Tension setting |

Tension elements of wrapping tape/pay-off/take-up/wrapping are servo motors, SOP process is stored in PLC. |

| Safety protection |

Comply with CE standard, with temperature/vibration/noise/pressure automatic detection and prediction. |

PRODUCT FEATURES

● High productivity: The rotating body is statically balanced and dynamically balanced for testing and correction. When running, the machine has a small vibration and a low voice. The spindle does not generate heat during long-term continuous high-speed operation. It has high production efficiency and cost-effectiveness.

● Stable tension: Three servo motors provide power respectively to precisely control the movement of the rotating frame, tape material tray, and tension dancer.

Various influencing factors such as changes in matrial spool or pad diameter and wind resistance are eliminated, resulting in stable tension.

● Accurate pitch: Taking the main capstan as the movement benchmark, the main capstan, and each rotating frame adopt a servo motion controller for precise interlocking motion control so that an accurate wrapping pitch can be obtained at any speed.

● Labor saving: A clamping device is installed at the wire inlet end of each wrapping head. The clamping force can be adjusted without damaging the wire; the wire can be withdrawn in the reverse direction; Configuration mode management, one-click retrieval of SOP formula, one-click startup preparation, and one-click start; Stop and shut down when the tape is broken/finished/metered, intelligent control, saving manpower.

● Low failure rate: no collector ring, no carbon brush, except for the regular replacement of wearing parts - the tape guiding roller, low failure rate.

● Easy maintenance: Using Profinet bus control, fast signal transmission, low interference, remote fault detection cability. Troubleshooting and maintenance are available no matter the machine is in any country in the world, as long as there is a communication network, then rapid remote maintenance services can be provided.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

2026-01-26

2026-01-26 Webmaster

Webmaster