Content

Direct Answer: What is Fish Tape and Its Primary Use?

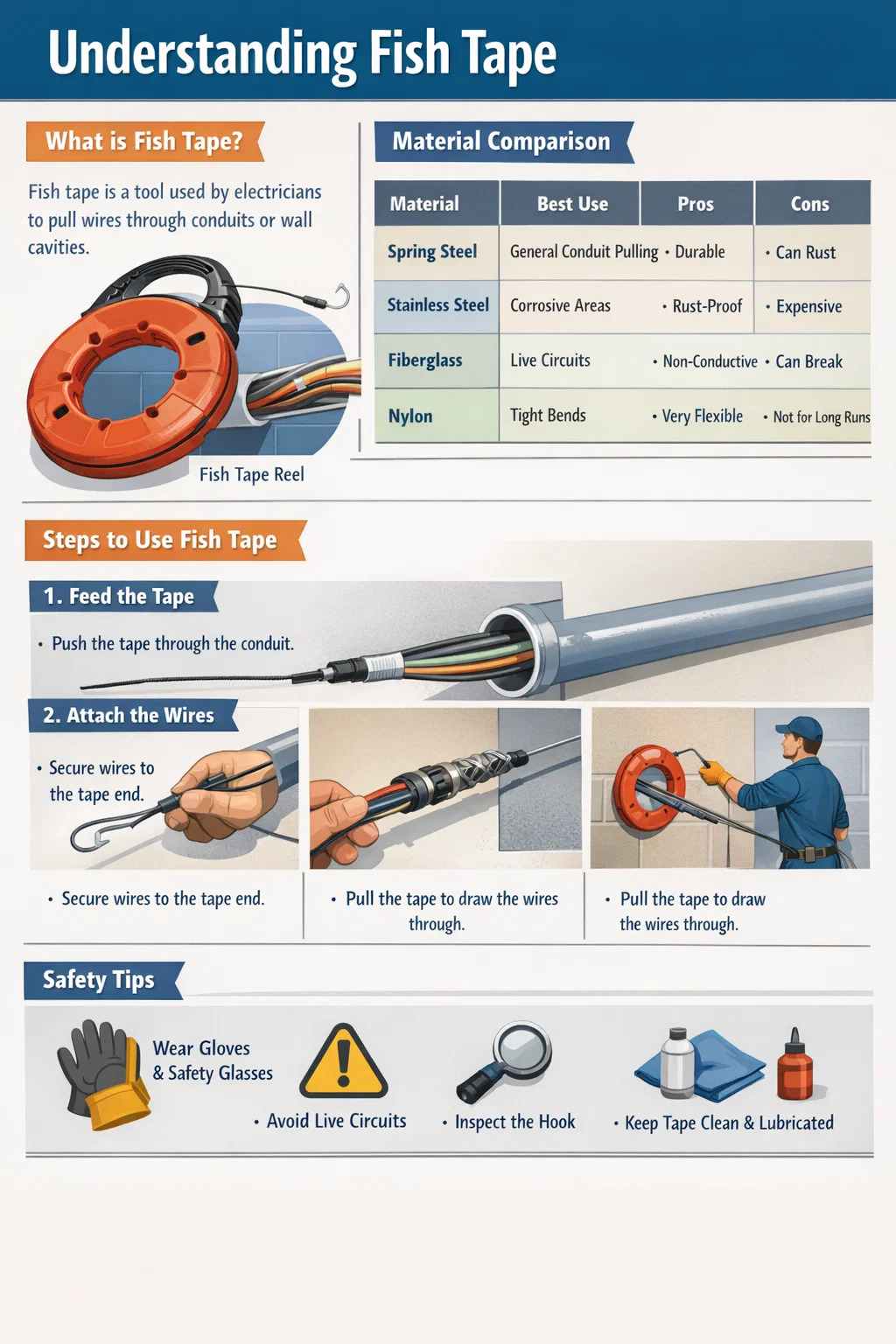

Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow openings, conduits, or wall cavities. It typically consists of a flat wire made of spring steel, stainless steel, or fiberglass, housed within a high-impact plastic reel. The primary purpose is to "fish" for a path through an obstructed area so that electrical conductors—often those high-quality wires produced by a wire and cable extruder—can be pulled back through the passage without damaging their insulation.

Components and Material Varieties

Understanding the makeup of your fish tape is essential for selecting the right tool for the job. Not all tapes are suitable for every environment, especially when dealing with live circuits or long, winding conduit runs.

| Material Type | Best Use Case | Pros | Cons |

|---|---|---|---|

| Spring Steel | General Conduit Pulling | Very durable; rigid enough for long runs. | Conductive; potential rust issues. |

| Stainless Steel | Corrosive Environments | Rust-proof; very high tensile strength. | Most expensive option. |

| Fiberglass | Live Circuits / Finished Walls | Non-conductive; lightweight and flexible. | Can snap if bent too sharply. |

| Nylon | Short, Complex Conduit Runs | Extremely flexible; won't damage plastic pipes. | Too soft for very long distances. |

Step-by-Step Guide to Using Fish Tape Correctly

Using fish tape effectively is a two-person job that requires coordination. One person "feeds" the wire while the other person "pulls" the tape. This ensures that the outer jacket of the cable—carefully formed by a wire and cable extruder to precise thickness—remains intact and functional.

Step 1: Feeding the Tape

Unwind the fish tape from the reel and push the hooked end into the conduit or wall cavity. Use short, firm strokes. If you encounter an obstruction, pull back slightly and rotate the tape while pushing again. The goal is to get the hook to emerge at the target junction box or exit point.

Step 2: Attaching the Wires

Once the hook is visible at the other end, it is time to attach your wires. Do not simply tie a knot; knots are bulky and will snag. Strip about 3 to 5 inches of insulation from your wires. Loop the bare copper through the fish tape eyelet and twist it back onto itself. Wrap the entire connection tightly with high-quality electrical tape to create a smooth, tapered profile.

Step 3: The Pull-Back Process

The person at the reel end begins to wind the tape back in. The person at the wire end must "feed" the wires into the conduit, ensuring they do not tangle. For long runs with multiple bends, apply wire pulling lubricant to the wires to reduce friction. This prevents excessive tension that could stretch or deform the wire, which was manufactured to strict tolerances by a wire and cable extruder.

Critical Maintenance and Safety Tips

Fish tape is a rugged tool, but improper care can lead to accidents or tool failure. Steel tapes are excellent conductors of electricity; never use them near energized circuits or inside panels that have not been fully de-energized.

- Always wear safety glasses and heavy-duty gloves. Fish tape can "spring" out of the reel with significant force, and steel edges can be sharp.

- Inspect the hook regularly. If the steel hook shows signs of cracking or fatigue, cut it off and bend a new one using a propane torch to soften the metal first.

- Keep the tape clean. Wipe away excess dirt and lubricant after every use before winding it back into the reel to prevent jamming.

- For fiberglass tapes, avoid sharp 90-degree bends which can cause the internal fibers to splinter, ruining the tape's structural integrity.

Advanced Techniques: Using Pulling Socks and Leaders

When pulling a large bundle of wires, the simple "twist and tape" method might fail under high tension. Professionals use a wire pulling grip (also known as a "pulling sock"). This mesh device tightens around the cable bundle as tension increases, distributing the force evenly across the cable jackets. This is particularly important for high-performance data cables, where the internal geometry set by the wire and cable extruder must be preserved for signal integrity.

If you are working in a conduit already crowded with existing wires, use a flexible leader. A leader is a small, multi-strand steel cable attached to the end of the fish tape that can navigate around obstacles and existing cables much more easily than a standard stiff hook.

Conclusion: Why the Right Tool Matters

Successful electrical installation relies on the synergy between quality tools and quality materials. By using fish tape correctly, you ensure that the high-quality products produced by a wire and cable extruder are installed without nicks, tears, or internal damage. Whether you are a DIY homeowner or a professional electrician, mastering the fish tape will save you hours of frustration and ensure a safer, more reliable electrical system.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products