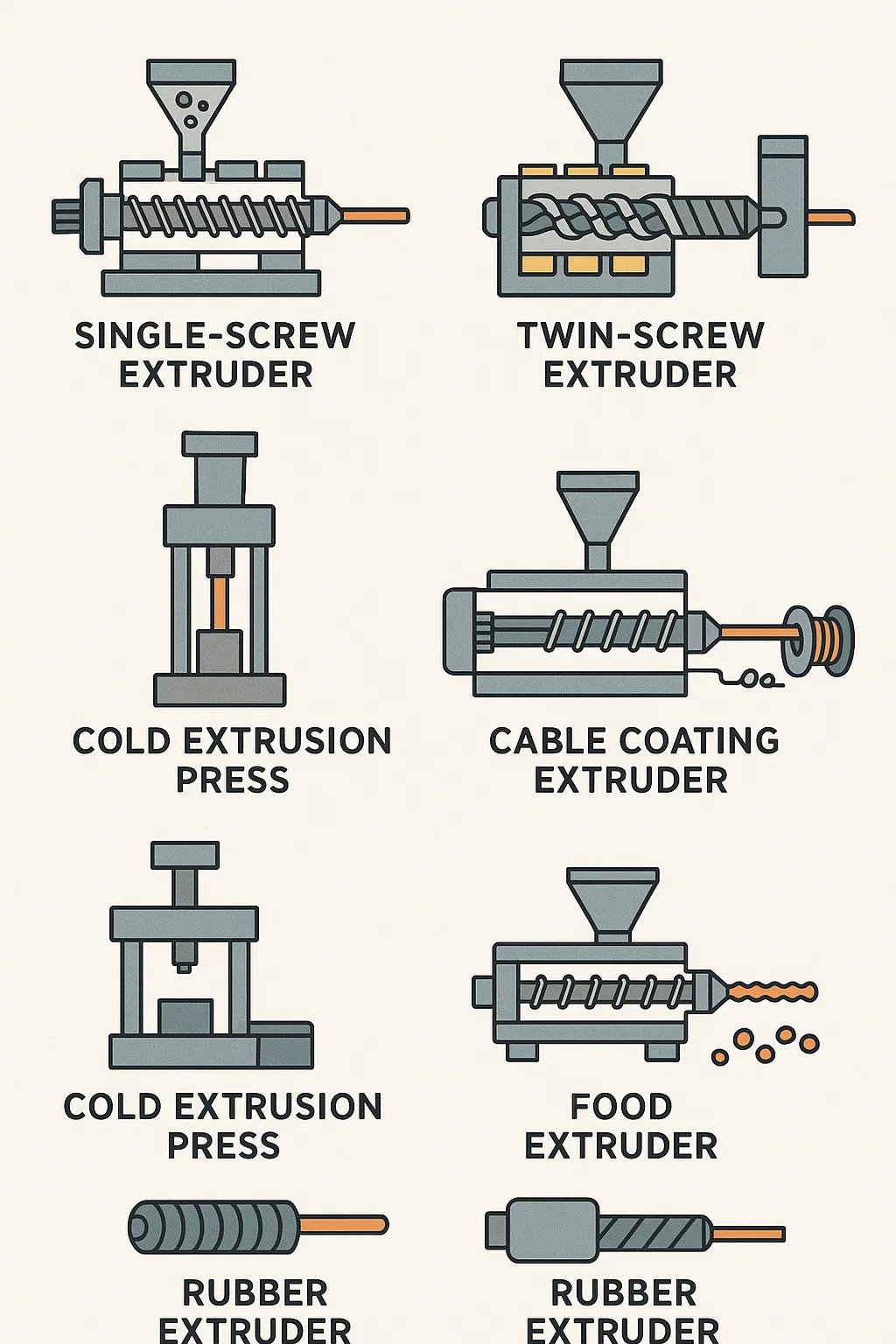

Here's a plain-English breakdown of common extrusion machine types used in factories:

Content

1. Single-Screw Extruder

How it works: A rotating screw pushes material (like plastic pellets) through a heated barrel, melting it.

Everyday uses: Making pipes, plastic sheets, or basic wire insulation.

Key trait: Simple design, good for straightforward jobs.

2. Twin-Screw Extruder

How it works: Two screws interlock inside the barrel, mixing materials thoroughly.

Everyday uses: Blending recycled plastics, making wood-plastic decking, or medical tubing.

Key trait: Handles sticky or tricky materials better than single-screw machines.

3. Ram Extruder

How it works: A piston rams material through a die (like a giant cookie press).

Everyday uses: Shaping clay bricks, ceramic tubes, or soft metals like lead.

Key trait: Good for thick, heavy pastes that can't be screw-pushed.

4. Cold Extrusion Press

How it works: Squeezes metals without heating – just brute force.

Everyday uses: Crafting aluminum cans, copper wiring, or steel bolts.

Key trait: Saves energy; keeps metal stronger than hot methods.

5. Cable Coating Extruder

How it works: Wraps melted plastic/rubber around wires as they feed through.

Everyday uses: Insulating electrical wires, adding waterproof jackets to cables.

Key trait: Precision dies ensure no gaps or bubbles in the coating.

6. Food Extruder

How it works: Pushes dough through shaped dies, then cooks it instantly.

Everyday uses: Making breakfast cereals, pasta shapes, or pet kibble.

Key trait: Combines shaping and cooking in one machine.

7. Rubber Extruder

How it works: Special screws handle sticky raw rubber without clogging.

Everyday uses: Car tire treads, seals for windows, or hoses.

Key trait: Tackles rubber's stretchiness better than plastic extruders.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products