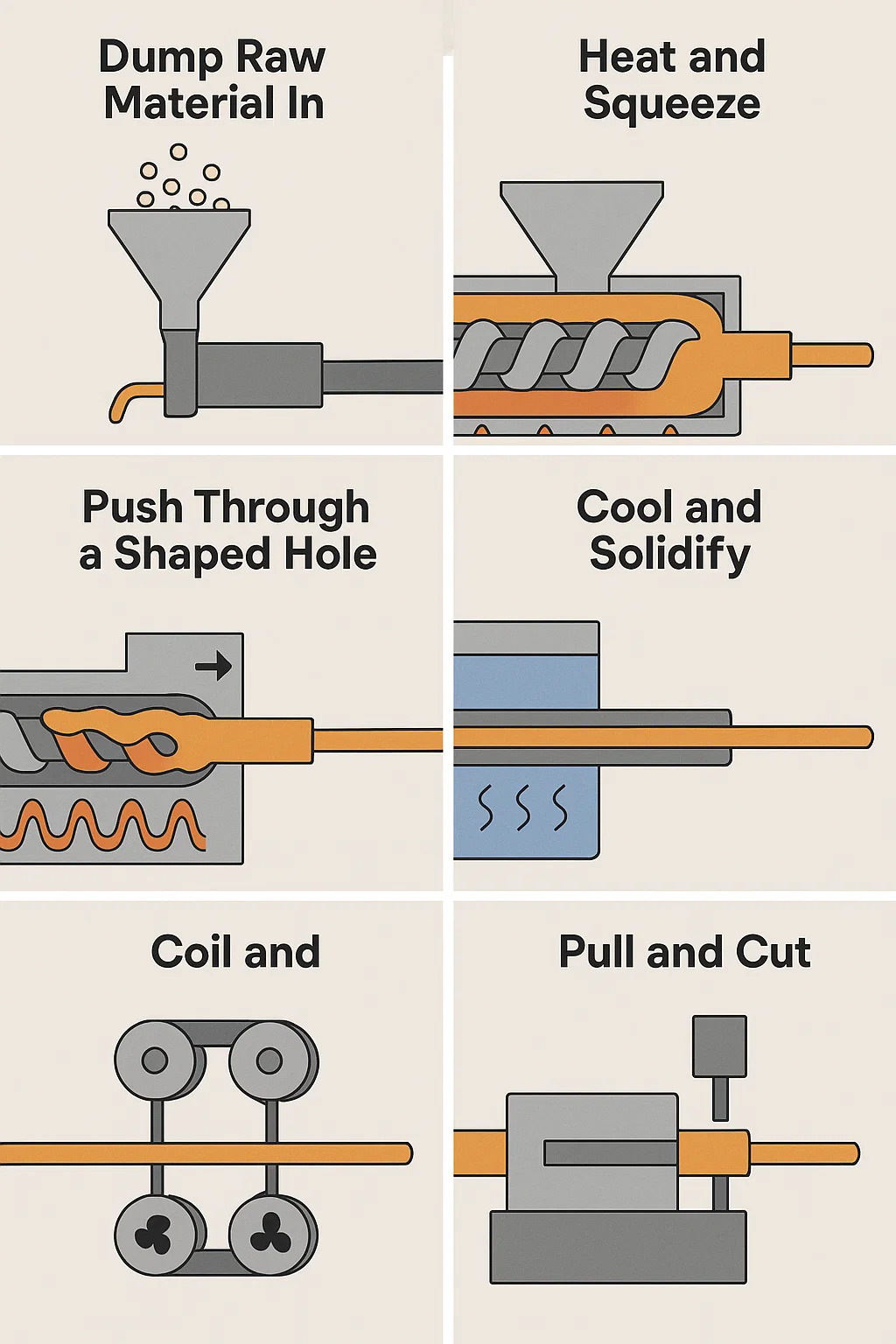

Here's how an extruder machine works, broken down simply:

Content

1. Dump Raw Material In

Plastic pellets, rubber crumbs, or food dough get poured into a hopper (funnel-like container) at the machine’s start.

2. Heat and Squeeze

A rotating screw inside a heated barrel churns the material like a dough mixer.

Friction and heaters melt solids into a soft, sticky paste.

3. Push Through a Shaped Hole

The spinning screw forces the melted goo forward into a die – a custom metal mold with an opening shaped like the final product (e.g., tube, wire coating, pasta strand).

Think of squeezing playdough through a toy mold: the die shapes the goo instantly.

4. Cool and Solidify

The warm, shaped material exits the die and moves through cooling zones:

Water tanks (like dunking hot metal in water)

Air blowers (like cooling baked cookies with a fan)

This hardens the material so it keeps its new shape.

5. Pull and Cut

A puller grips the cooled product gently, dragging it forward at steady speed.

Cutters or winders then trim or spool the finished lengths (pipes, cables, etc.).

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products