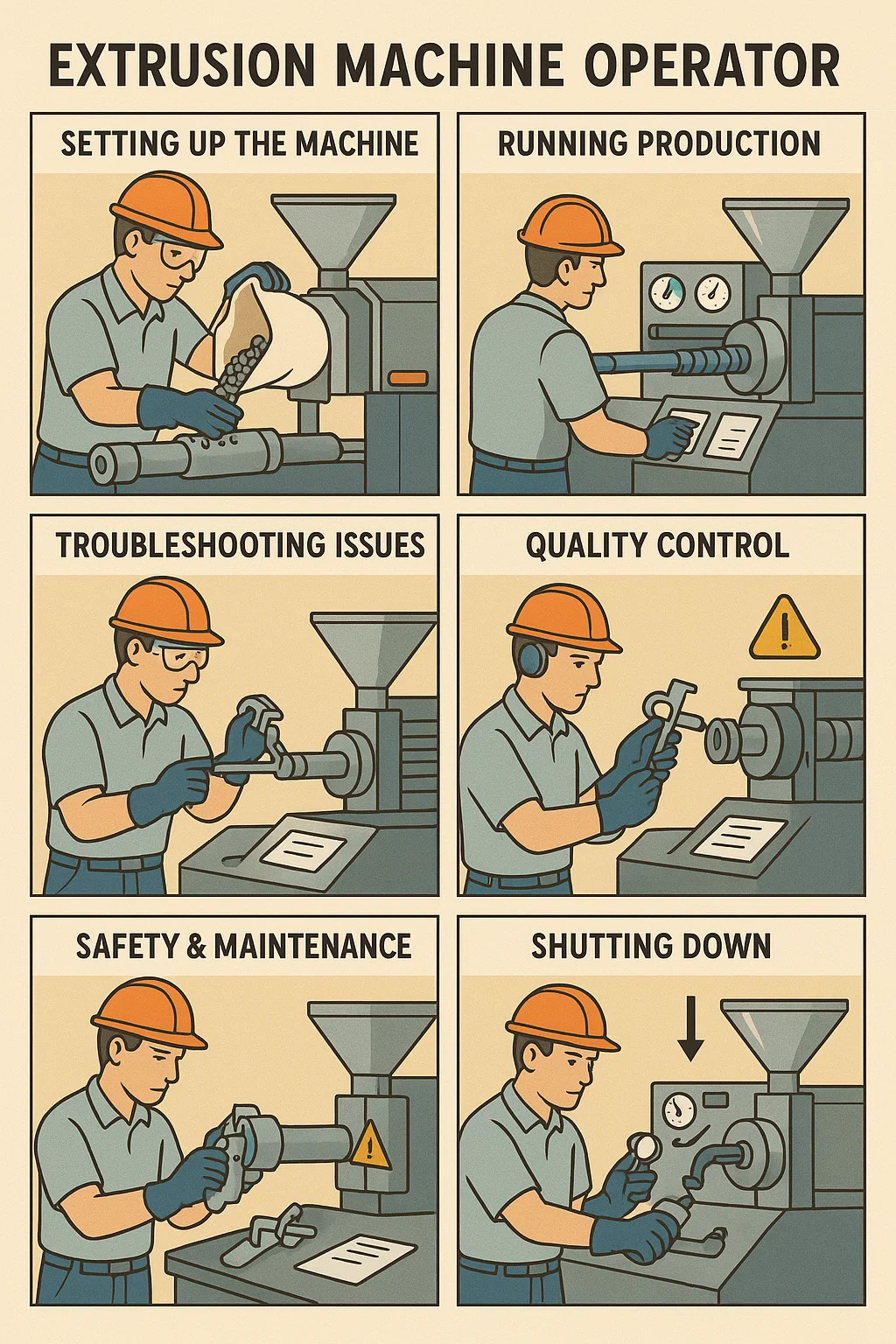

Here's what an extrusion machine operator does daily:

Content

1. Setting Up the Machine

Prepares materials: Loads plastic pellets, rubber, or powders into the hopper.

Installs tools: Swaps out dies or screws to match the product being made (e.g., pipe, wire coating).

Heats the barrel: Adjusts barrel temperatures to melt materials properly.

2. Running Production

Starts the line: Powers up the extruder, conveyor, and cooling systems.

Monitors gauges: Watches temperature, pressure, and speed readouts to catch problems early.

Feeds material: Keeps the hopper filled to avoid interruptions.

3. Troubleshooting Issues

Fixes jams: Clears clogs in the die or screw when material sticks.

Adjusts settings: Tweaks heat, screw speed, or puller tension if the product looks wrong (e.g., bubbly coating, uneven shapes).

Checks quality: Spots flaws like scratches, lumps, or size errors.

4. Quality Control

Measures products: Uses calipers or gauges to check thickness/diameter.

Tests samples: Cuts small pieces to verify strength or flexibility.

Keeps records: Logs production amounts, defects, and machine settings.

5. Safety & Maintenance

Wears gear: Uses gloves, goggles, and ear protection near hot/noisy machines.

Cleans regularly: Wipes down screws, dies, and hoppers to prevent contamination.

Lubricates parts: Oils moving components to reduce wear.

6. Shutting Down

Cools the machine: Gradually lowers temperatures before stopping.

Purges residue: Runs cleaning pellets through to flush out leftover material.

Inspects equipment: Looks for worn screws, leaks, or electrical issues.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products