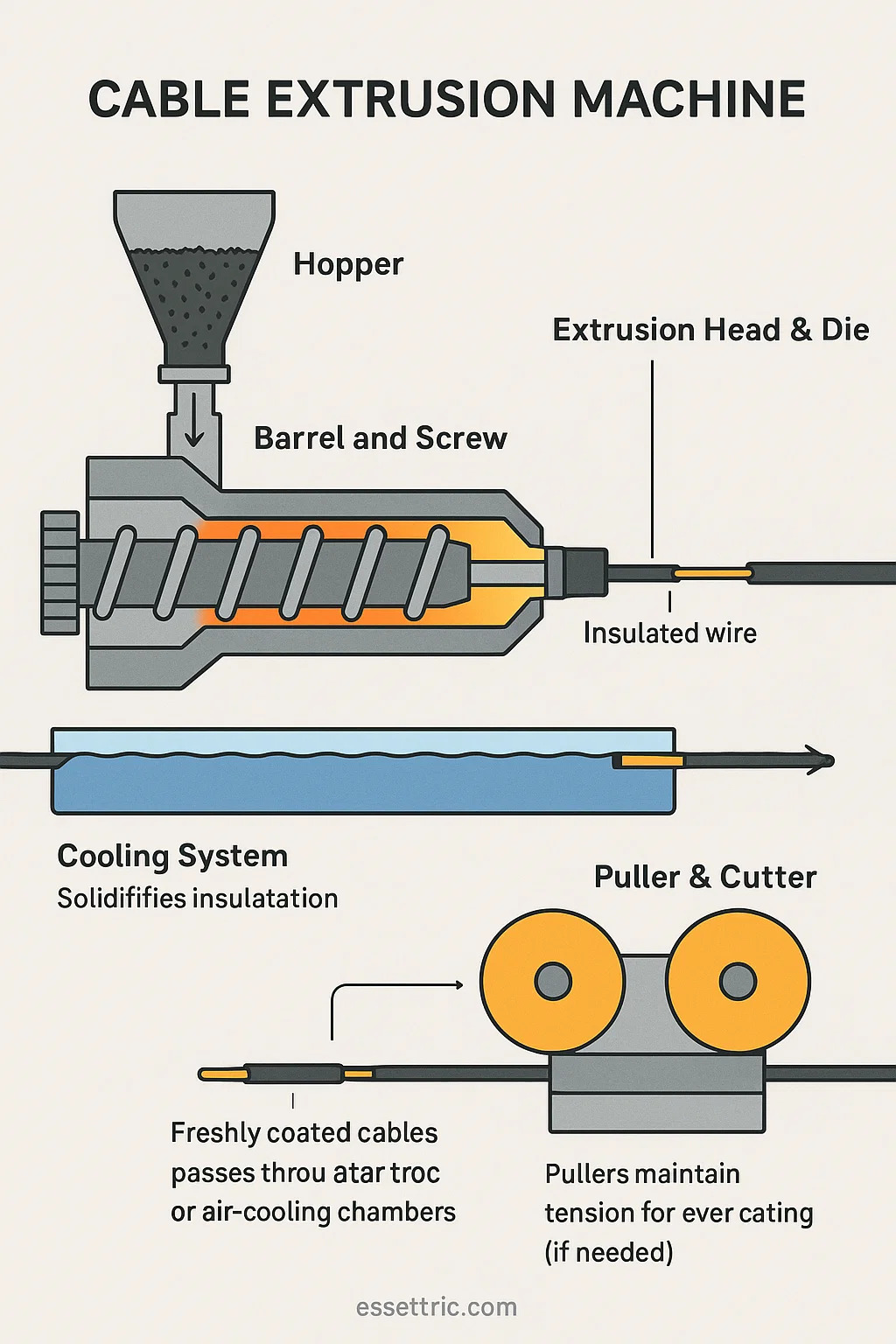

A cable extrusion machine is central to wire and cable manufacturing. It applies protective or functional layers—like insulation or outer sheathing—onto conductors. Here’s how it works in practice:

●Core Function

Material Coating — Melts raw plastic or rubber compounds (e.g., PVC, XLPE) into a fluid state. — Uniformly coats wires or cable cores as they pass through the machine.

●Key Components

▸Hopper

— Raw material (pellets/powder) is fed here. Gravity moves it into the barrel.

▸Barrel and Screw

— The barrel heats material while a rotating screw mixes and pushes it forward.

— Gradually melts the material into a viscous fluid.

▸Extrusion Head & Die

— Molten material is forced through the head.

— A precisely shaped die molds it around the moving conductor.

▸Cooling System

— Freshly coated cables pass through water troughs or air-cooling chambers.

— Solidifies the insulation/sheathing quickly to retain shape.

▸Puller & Cutter

— Pullers maintain tension for even coating.

— Cutters trim cables to preset lengths (if needed).

| Aspect | Description |

| Primary Function | Applies insulation, sheathing, or functional layers onto wires/cable cores. |

| Core Components | - Hopper: Feeds raw material (e.g., PVC, XLPE pellets). - Barrel & Screw: Heats, melts, and mixes material. - Die: Shapes molten material around the conductor. - Cooling System: Solidifies coating (water/air). - Puller: Maintains tension during extrusion. |

| Process Flow | 1. Conductor fed into machine. 2. Material melted in barrel. 3. Die coats conductor. 4. Cooling sets the layer. 5. Cable wound onto reels. |

| Key Outputs | - Insulated wires. - Jacketed multi-core cables. - Shielding/semi-conductive layers. |

| Specialized Features | - Dual extrusion: Applies two layers simultaneously. - Cross-linking: Enhances material strength (e.g., XLPE). - Color striping: Adds identification lines. |

| Material Flexibility | Works with thermoplastics (PVC, PE), rubber, and cross-linked polymers. |

| Customization | Adjusts for coating thickness, diameter, and material via interchangeable dies. |

| Quality Control | Sensors monitor thickness uniformity; auto-adjusts temperature/speed. |

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products