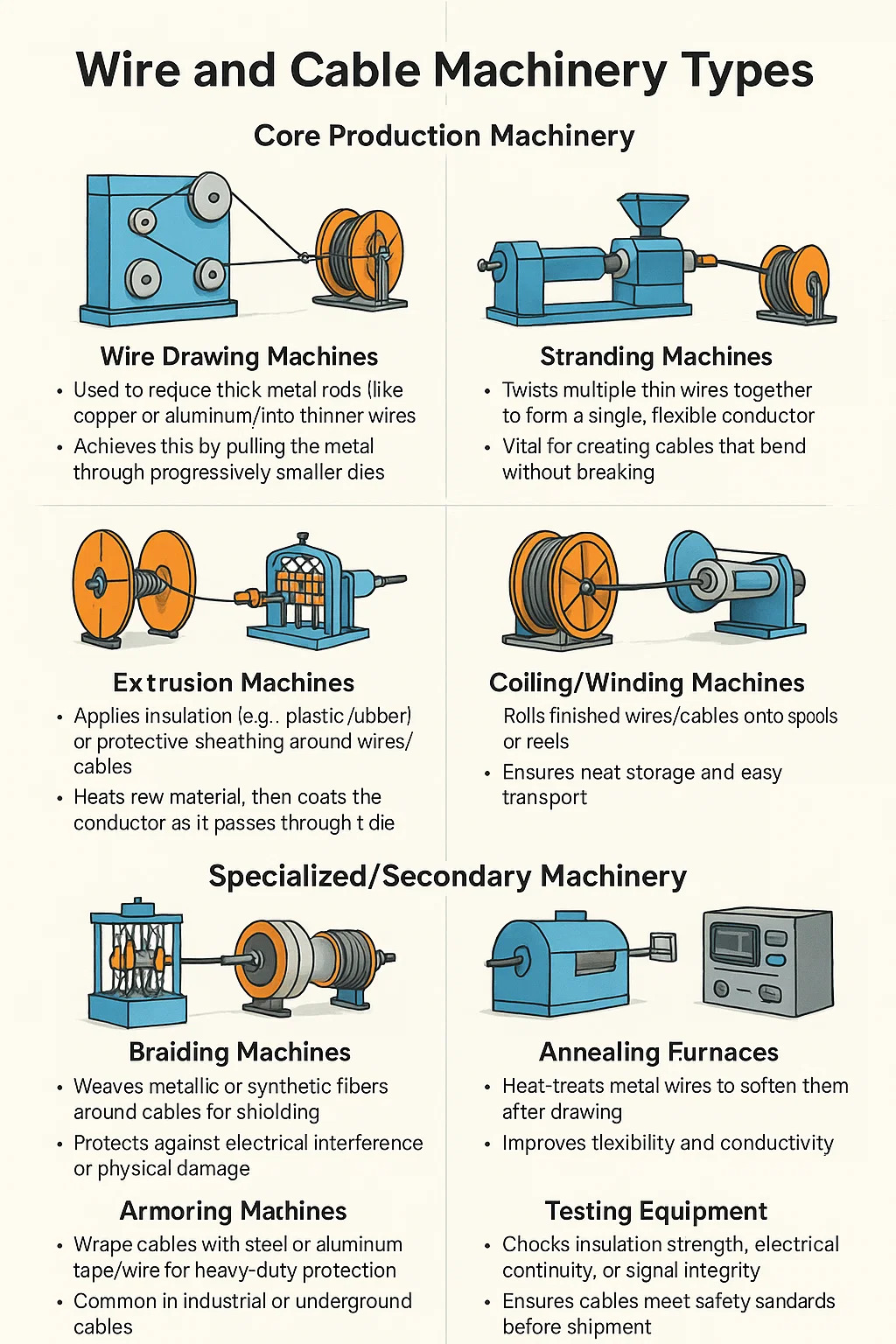

Based on common industry knowledge, here's a breakdown of wire and cable machinery types:

●Core Production Machinery

Wire Drawing Machines

— Used to reduce thick metal rods (like copper or aluminum) into thinner wires.

— Achieves this by pulling the metal through progressively smaller dies.

●Stranding Machines

— Twists multiple thin wires together to form a single, flexible conductor.

— Vital for creating cables that bend without breaking.

●Extrusion Machines

— Applies insulation (e.g., plastic, rubber) or protective sheathing around wires/cables.

— Heats raw material, then coats the conductor as it passes through a die.

●Coiling/Winding Machines

— Rolls finished wires/cables onto spools or reels.

— Ensures neat storage and easy transport.

●Specialized/Secondary Machinery

Braiding Machines

— Weaves metallic or synthetic fibers around cables for shielding.

— Protects against electrical interference or physical damage.

●Armoring Machines

— Wraps cables with steel or aluminum tape/wire for heavy-duty protection.

— Common in industrial or underground cables.

●Annealing Furnaces

— Heat-treats metal wires to soften them after drawing.

— Improves flexibility and conductivity.

●Testing Equipment

— Checks insulation strength, electrical continuity, or signal integrity.

— Ensures cables meet safety standards before shipment.

●Support Machinery

Wire Cleaning/Treatment Lines

— Removes oxides, oils, or residues from metal surfaces before insulation.

— Ensures strong adhesion of coatings.

●Marking Machines

— Prints text (e.g., specs, brand names) directly onto cable sheaths.

— Uses ink jets or embossing.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products