Wire and cable stranding is a manufacturing process that bundles multiple wires or strands into a unified conductor.

Content

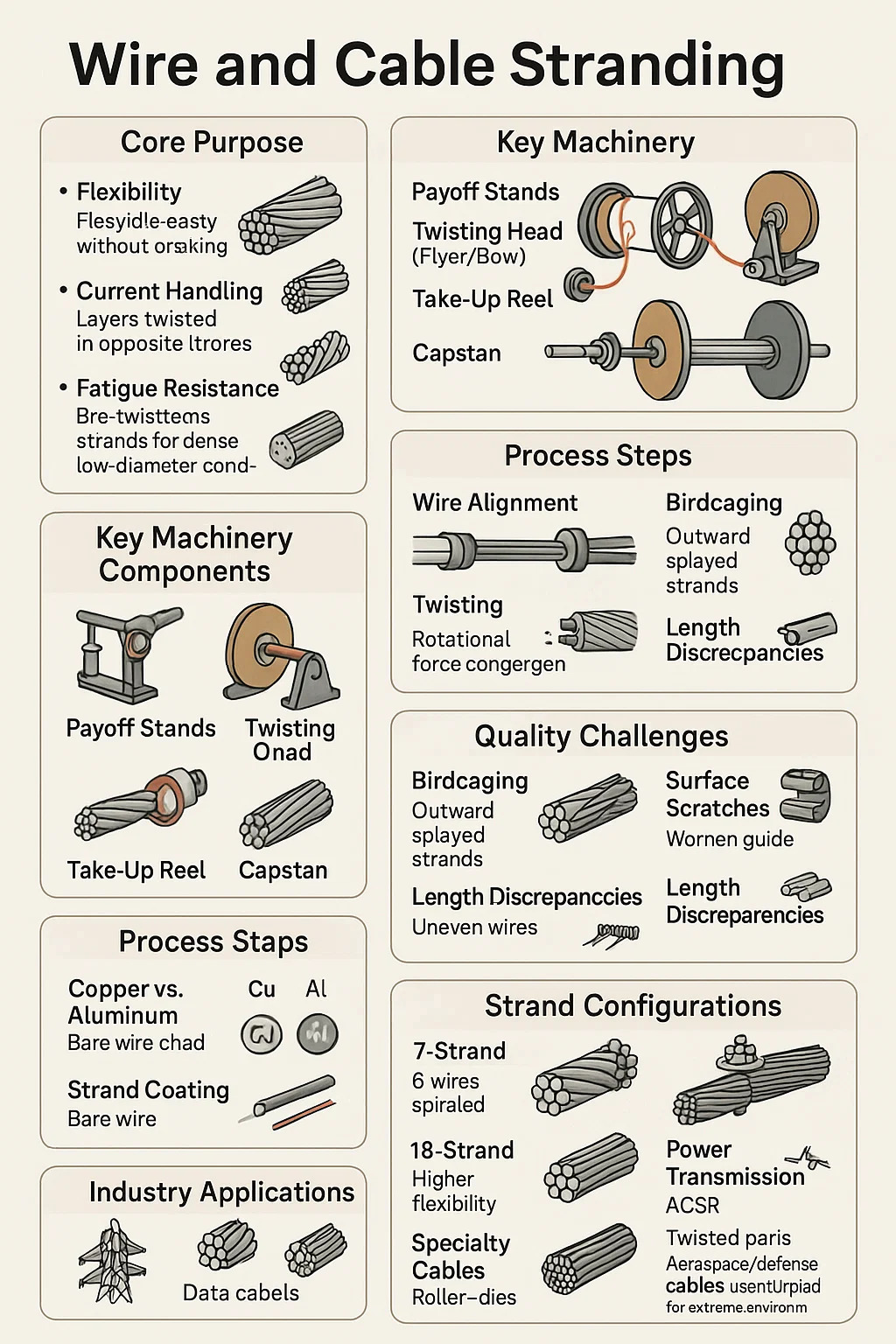

■Core Purpose

Flexibility — Stranded conductors bend easily without breaking, unlike rigid solid wires.

Current Handling — Multiple thin strands collectively carry higher currents than a single thick wire of equivalent cross-section.

Fatigue Resistance — Stranded designs withstand vibration (e.g., in vehicles/machinery) without fracturing.

■Stranding Methods

Bunch Stranding — Wires randomly grouped for basic flexibility (e.g., appliance cords).

Concentric Stranding — Layers twisted in opposite directions around a central core (e.g., power cables).

Rope Stranding — Groups of pre-twisted strands re-twisted together (e.g., crane cables, elevator ropes).

■Key Machinery Components

Payoff Stands — Hold individual wire spools, feeding them at controlled tension.

Twisting Head (Flyer/Bow) — Rotates to impart twist; bow-types suit larger cables.

Take-Up Reel — Collects stranded conductor, maintaining consistent tension.

Capstan — Pulls wires through the system without slippage.

■Process Steps

Wire Alignment — Strands guided through ceramic or PTFE tubes to prevent tangling.

Twisting — Rotational force applied as wires converge.

Lay Length Control — Adjusts twist tightness (e.g., tight for flexibility, loose for rigidity).

Closing Die — Compacts strands into final shape/size.

■Material Considerations

Copper vs. Aluminum — Copper strands easily; aluminum requires softer alloys to avoid brittleness.

Strand Coating — Bare metal for conductivity, or tinned/enameled for corrosion resistance.

■Quality Challenges

Birdcaging — Strands splay outward if tension is unbalanced—solved with backtwist mechanisms.

Surface Scratches — Abrasive guides damage wires; polished ceramics prevent this.

Length Discrepancies — Uneven payoffs cause "bunching" defects.

■Strand Configurations

7-Strand — 6 wires spiraled around 1 core (common in automotive wiring).

19-Strand — Higher flexibility for robotics/medical cables.

Compact Strands — Roller-dies compress strands for dense, low-diameter conductors.

■Industry Applications

Power Transmission — ACSR (aluminum conductor steel-reinforced) for overhead lines.

Data Cables — Twisted pairs reduce electromagnetic interference.

Specialty Cables — Aerospace/defense cables use nickel-plated strands for extreme environments.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products