An automatic cable taping machine applies adhesive-backed tapes or films precisely onto cables during production. Here's a breakdown of its function and features:

Content

●Core Purpose

▸Insulation/Barrier Layer ulation/Barrier Layer — Wraps tapes (e.g., polyester, PVC, aluminum.g., polyester, PVC, aluminum foil) around conductors to provide electrical insulation, moisture resistance, or EMI shielding.

▸Conductor Binding — Secures stranded wires into a compact shape before jacketing.

▸Fire Protection — Applies flame-retardant mica tapes for fire-survival cables.

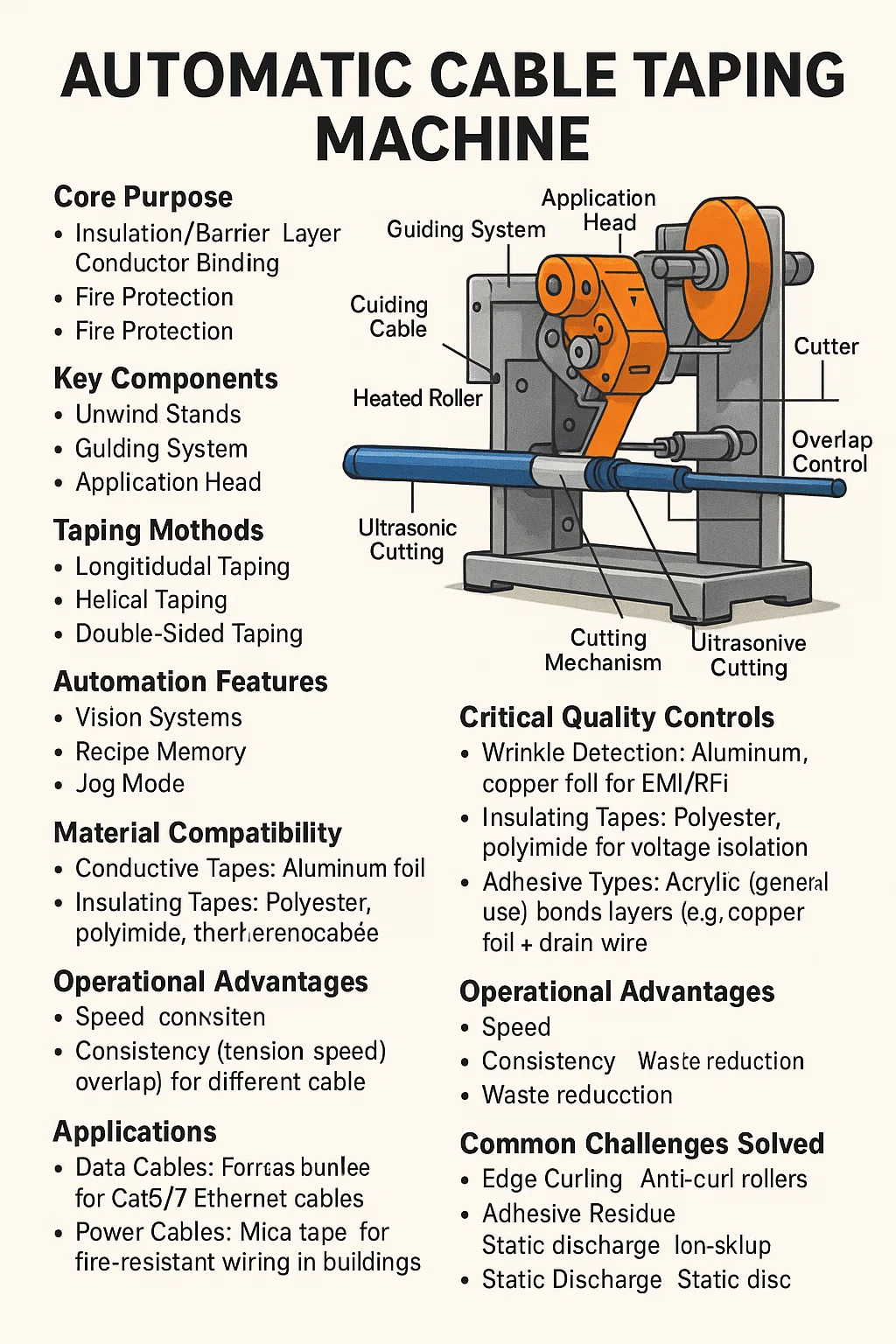

●Key Components

▸Unwind Stands — Holds tape reels with tension control to prevent slack or tearing.

▸Guiding System — Aligns tape and cable using laser sensors or servo-controlled rollers.

▸Application Head — Presses tape onto the cable via heated rollers (for adhesives) or cold pressure.

▸Cutting Mechanism — Trims tape at cable ends or during splicing; ultrasonic during splicing; ultrasonic cutters avoid fraying.

▸Overlap Control — Adjusts tape edge alignment for consistent coverage (e.g., 25% overlap).

●Taping Methods

▸Longitudinal Taping — Tape runs parallel to the cable length (common for shielding).

▸Helical Taping — Tape spirals around the cable (flexible for curved paths).

▸Double-Sided Taping — Adhesive on both sides bonds layers (e.g., copper foil + drain wire).

●Automation Features

▸Vision Systems —- Vision Systems — Cameras detect tape gaps/misalignment, triggering auto-correction.

▸Recipe Memory — Stores settings (tension, speed, overlap) for different cable diameters.

▸Jog Mode — Slow-motion adjustment during setup to minimize tape waste.

●Material Compatibility

▸Conductive Tapes — Aluminum, copper foil for EMI/RFI shielding.

▸Insulating Tapes — Polyester, polyimide for voltage isolation.

▸Adhesive Types — Acrylic (general use), thermosetting (high-temp cables), or pressure-sensitive.

●Critical Quality Controls

▸Wrinkle Detection — Sensors halt production if tape folds or bubbles form.

▸Tension Feedback Loops — Prevents tape stretching or breakage during speed changes.

▸Adhesive Activation Monitoring — Infrared sensors verify proper bonding temperature.

●Applications

▸Data Cables — Foil shielding for Cat6/7 Ethernet cables.

▸Power Cables — Mica tape for fire-resistant wiring in buildings.

▸Coaxial Cables — Aluminum tape + braid for signal integrity.

▸Automotive Harnesses — Tapes bundle wires before — Tapes bundle wires before overmolding.

●Operational Advantages

▸Speed — Processes cables continuously at line speeds >100 m/min.

▸Consistency — Eliminates human error in tape alignment/adhesion.

▸Waste Reduction — Precision cutting minimizes tape scraps.

●Common Challenges Solved

▸Edge Curling — Anti-curl rollers flatten tape during application.

▸Adhesive Residue — Non-stick rollers and cleaning cycles prevent buildup.

▸Static Discharge — Ionizing bars neutralize static on non-conductive tapes.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products