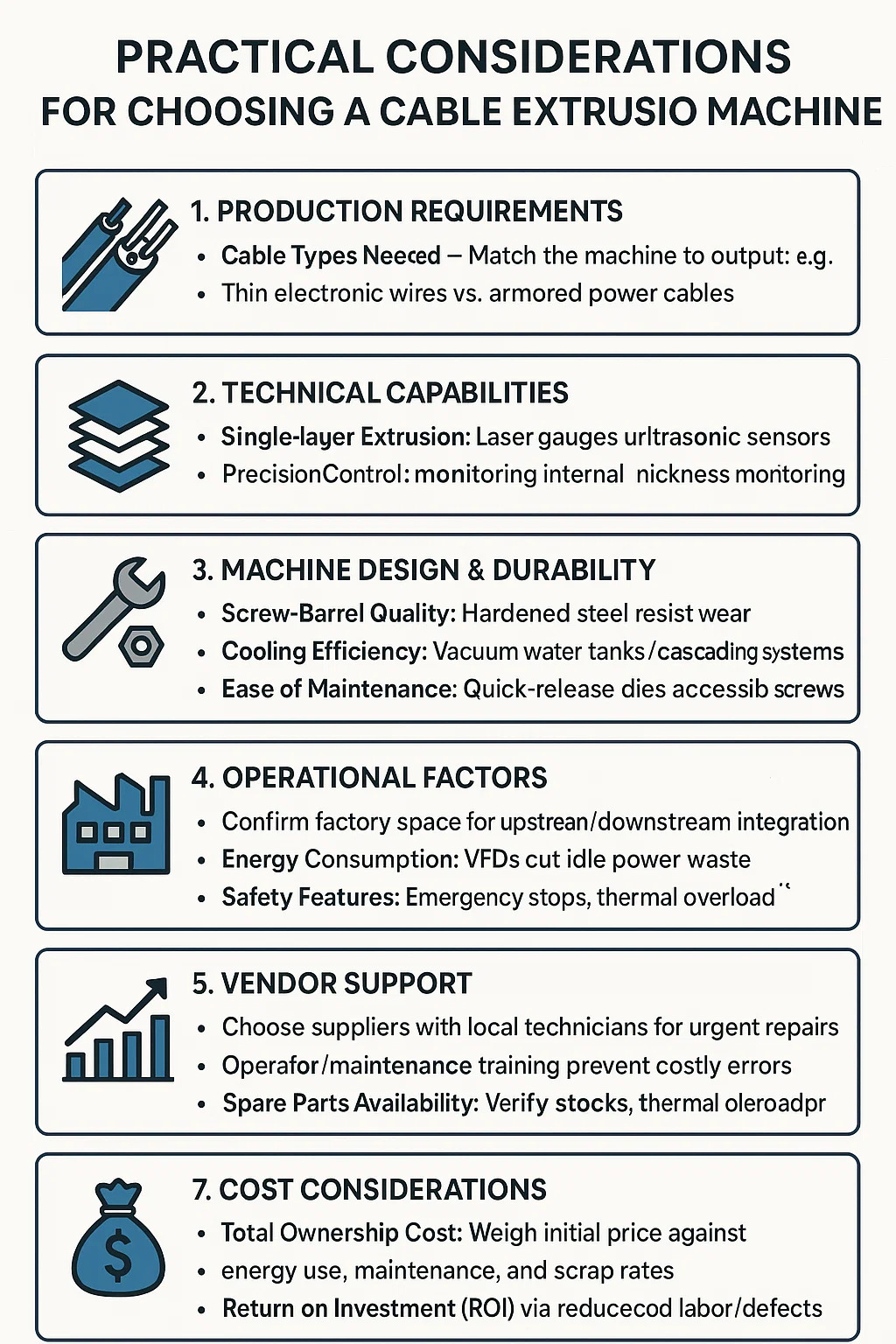

When selecting a cable extrusion machine, prioritize these practical considerations based on industry experience:

1. Production Requirements

Cable Types Needed — Match the machine to your output: e.g., thin electronic wires vs. armored power cables.

Output Volume — High-volume lines need automated, continuous systems; small batches suit modular setups.

Material Compatibility — Ensure the machine processes your polymers (e.g., PVC, XLPE, TPE) without degradation.

2. Technical Capabilities

Extrusion Layers — Single-layer for basic wires; dual/triple extrusion for complex cables (shielding + jacket).

Precision Control — Laser gauges or ultrasonic sensors for real-time thickness monitoring.

Line Speed — Balance throughput with stability—high speeds risk defects if cooling/tension falters.

3. Machine Design & Durability

Screw-Barrel Quality — Hardened steel resists wear from abrasive compounds (e.g., silica-filled XLPE).

Cooling Efficiency — Vacuum water tanks or cascading systems prevent bubbles/voids in thick insulation.

Ease of Maintenance — Quick-release dies and accessible screws reduce downtime during changeovers.

4. Operational Factors

Footprint & Layout — Confirm factory space for upstream/downstream integration (e.g., stranding → extrusion → coiling).

Energy Consumption — Variable-frequency drives (VFDs) cut idle power waste.

Safety Features — Emergency stops, thermal overload protection, and guarded moving parts.

5. Vendor Support

Technical Service — Choose suppliers with local technicians for urgent repairs.

Training — Operator/maintenance training prevents costly errors.

Spare Parts Availability — Verify stocks of critical components (heaters, screws, dies).

6. Future-Proofing

Modular Upgrades — Can the machine add IoT monitoring or automation later?

Material Flexibility — Adaptability to newer polymers (e.g., halogen-free flame retardants).

Compliance — Meets evolving safety/environmental standards (RoHS, REACH).

7. Cost Considerations

Total Ownership Cost — Weigh initial price against energy use, maintenance, and scrap rates.

Return on Investment (ROI) — Higher automation may justify cost via reduced labor/defects.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products