The working process of an extrusion machine is similar to squeezing toothpaste or using a piping bag to decorate a cake. It uses pressure to force softened material through a specifically shaped opening, creating a long, continuous product.

Content

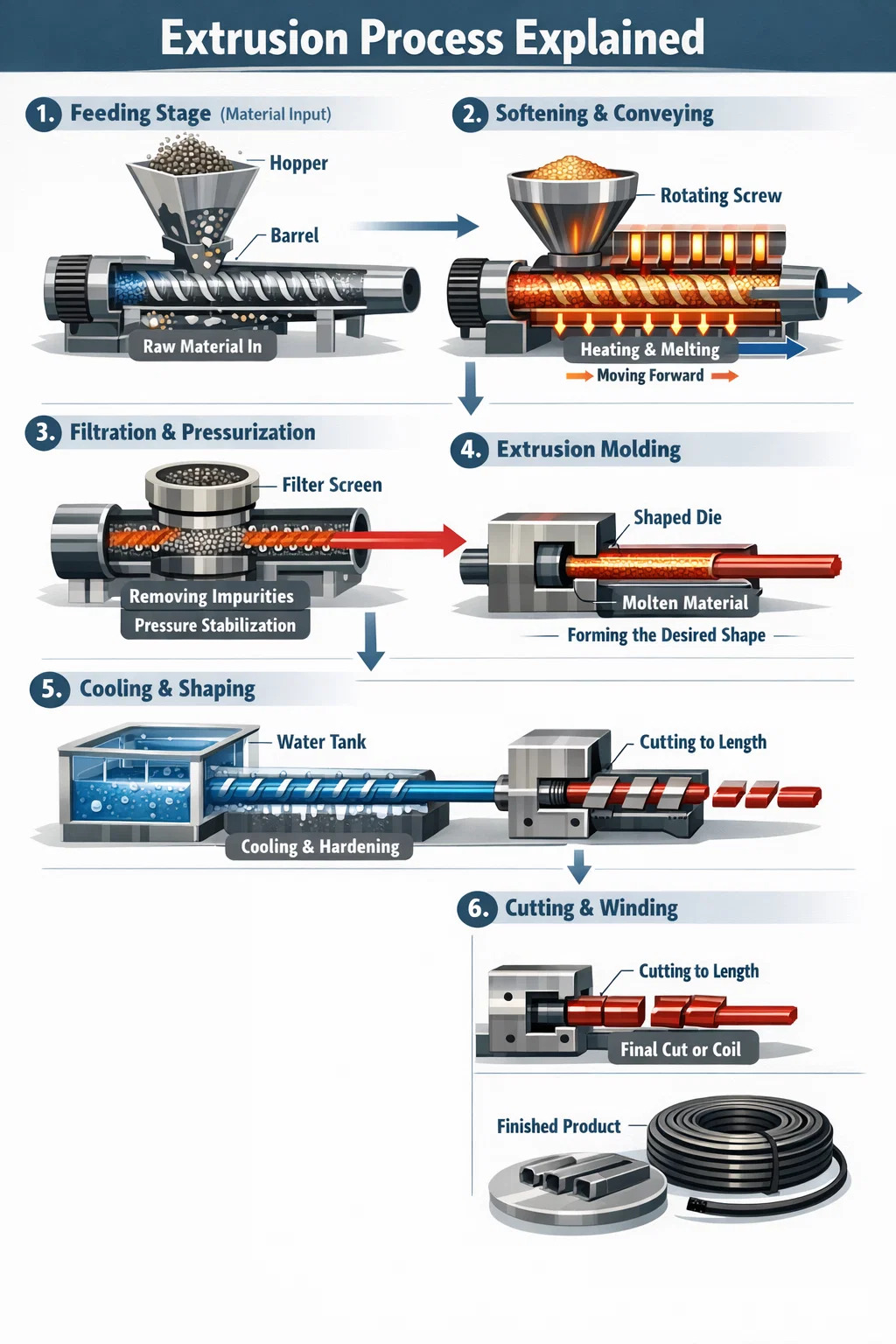

Here are the specific steps of how an extrusion machine works:

1. Feeding Stage (Material Input)

First, the raw materials (usually small granules of plastic, powder, or metal pieces) are poured into a "hopper" at the top of the machine. These materials fall into the machine's long cylinder (barrel) due to gravity.

2. Softening and Conveying (Transport and Plasticization)

Inside the barrel, a "screw" resembling a giant screw rotates continuously.

Conveying: As the screw rotates, it acts like a screw conveyor, pushing the raw materials towards the outlet.

Softening: During this process, heaters on the outside of the barrel heat the raw materials. Simultaneously, the friction and compression generated by the rotating screw cause the materials to gradually heat up, melt, and become a viscous, paste-like substance.

3. Filtration and Pressurization (Homogenization)

Once the raw materials have completely turned into a "paste," they are pushed towards a filter screen.

Removing Impurities: The filter screen blocks any unmelted lumps or impurities in the raw materials.

Pressure Stabilization: After this stage, the material pressure becomes very uniform, ensuring that the extruded product has a consistent thickness.

4. Extrusion Molding (Die Forming)

This is the most crucial step. The raw material is forcefully pushed into a metal part called a "die."

The die's outlet is a hole with a specific shape (e.g., a circular hole, a square hole, or a complex window frame shape).

As the material passes through this hole, it takes on the exact shape of the hole, forming a long, continuous strip.

5. Cooling and Shaping

The newly extruded strip is still soft and hot, making it prone to deformation.

The machine usually has a large water tank or a device that blows cold air at the end.

The strip passes through the water or cold air, rapidly cooling and hardening, fixing it into the desired shape. 6. Cutting and Winding

Finally, the hardened finished product is automatically cut into sections or wound into a coil, similar to electrical wire, thus completing one full cycle of the extrusion machine's operation.

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

Related Products

Related Products