Product Category

Product Category

Sheath extrusion is to cover the twisted wire with an annular sleeve. The sheath layer plays an important role in fixing the internal physical structure of multi-stranded core wires and providing external insulation protection. The outer sheath layer of cable is in direct contact with external objects. Its mechanical strength, electrical characteristics, environmental protection, fatigue resistance, weather resistance, etc. vary depending on the application field. In order to meet the need requirements, the commonly used sheath extrusion has the following types: according to the different environmental protection requirements of the sheath material, it is divided into environmentally friendly non-toxic material extrusion and non-environmental protection material extrusion; according to the different fire resistance and flame retardant requirements of the sheath layer, it is divided into low smoke halogen-free flame retardant extrusion and non-flame retardant material (i.e. conventional material) extrusion; according to different voltage levels, it is divided into small-sized low-voltage wire outer sheath extrusion, and large medium high-voltage power cable outer sheath extrusion. According to the different solidization molding processes of the sheath layer after extrusion, it is divided into ordinary water tank cooling molding and high-temperature drying tunnel irradiation cross-linking molding (or other cross-linking methods). According to different wire application fields, it is divided into wire sheath extrusion and cable sheath extrusion.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

2026-01-12

2026-01-12

Webmaster

Webmaster

Replacing the cables on a wire and cable extruder is a maintenance task that requires care and patience. Here, "cables" typically refers to the power

Read More +

2026-01-05

2026-01-05

Webmaster

Webmaster

In the wire and cable industry, there are numerous manufacturers of wire and cable extruders. Based on the size of the manufacturers, their technologi

Read More +

In the wire and cable manufacturing industry, sheath extruders play a central role, determining not only product quality and durability but also directly impacting production efficiency and cost control. As a leading company in this field, Gemwell Electrical Technology (Jiangsu) Co., Ltd. leverages its extensive technical expertise and reliable service commitment to provide comprehensive support to global customers.

1. What is the basic working principle of a wire and cable sheath extrusion machine?

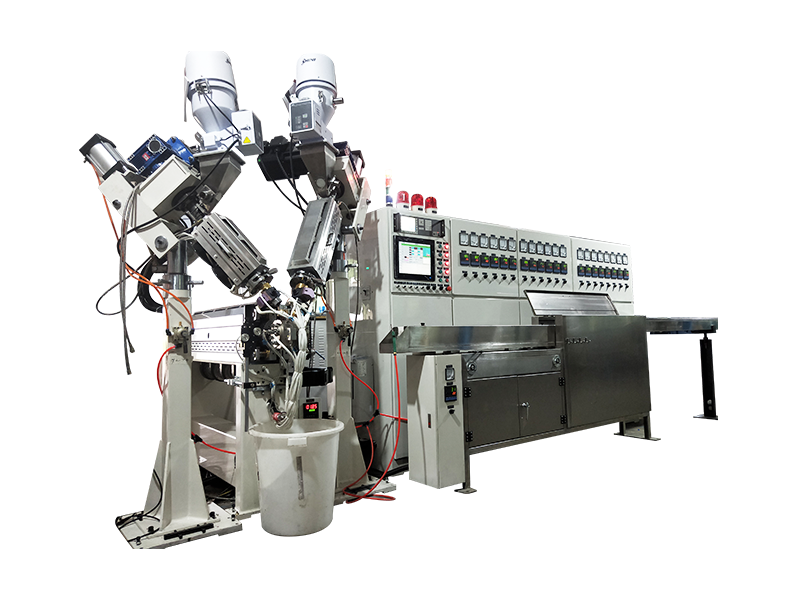

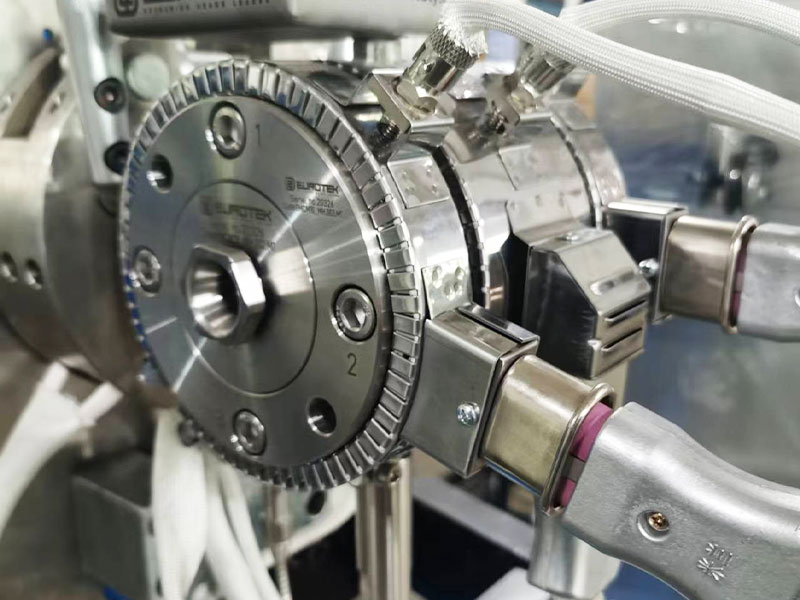

A wire and cable sheath extrusion machine is a specialized machine that melts and extrudes thermoplastics to form a uniform protective layer on the surface of wires or cables. Its core mechanism involves a feed system, a screw extrusion unit, and a cooling and shaping section. Raw material (such as polyethylene or polyvinyl chloride) is fed into a hopper and heated to a molten state by the rotating screw. The melt is then extruded through a die head, forming a continuous sheath layer. Finally, the sheath is rapidly solidified by a water or air cooling system. This process requires precise temperature and pressure control to ensure the sheath's thickness, density, and surface finish meet industry standards. When providing this type of machine, Gemwell Electrical Technology emphasizes its intelligent temperature control system, which ensures efficient and stable operation. Furthermore, its 24-hour rapid response service ensures immediate technical support for customers in the event of any operational anomalies, avoiding production interruptions.

2. What materials are commonly used in wire and cable sheath extrusion machine? How does the choice of these materials affect the performance of the final product?

Wire and cable sheath extrusion machines commonly process thermoplastic materials such as polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), and specialty rubbers. Material selection directly impacts the sheath's mechanical strength, weather resistance, insulation properties, and environmental performance. For example, PE is often used in outdoor cables due to its excellent chemical resistance and low-temperature toughness, while PVC is widely used in building cables for its cost-effectiveness and flame retardancy. Mismatched material melt indexes or improper additive ratios can lead to bubbles, cracks, or uneven shrinkage in the sheath, reducing the cable's service life. Gemwell Electrical Technology incorporates material compatibility optimization technology into its machine design to help customers avoid these defects. Furthermore, thanks to the company's one-year quality assurance, customers can receive timely professional diagnosis and solutions if they encounter performance fluctuations during the material application phase, ensuring their products consistently meet standards.

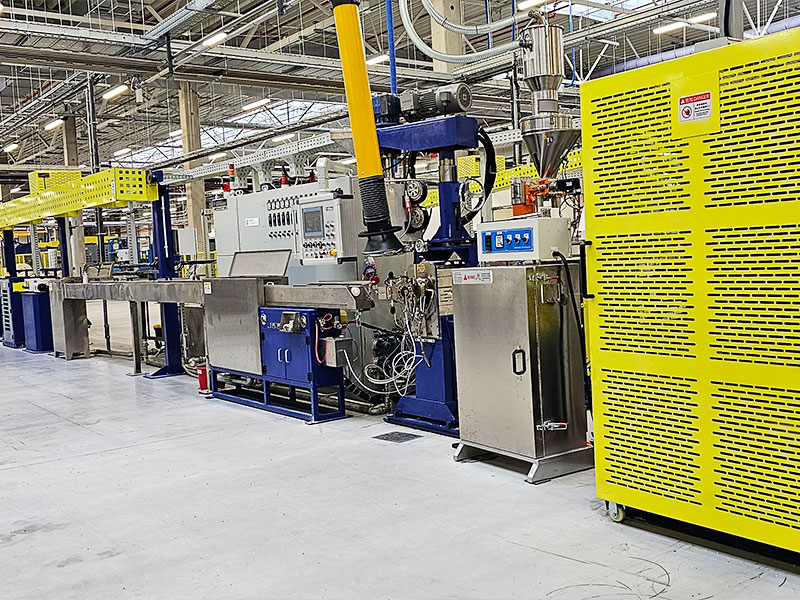

3. What are the main application areas for wire and cable sheath extrusion machines? How do their technological advantages drive industry development?

These machines are widely used in power transmission, communications networks, automotive electronics, and building infrastructure. For example, in high-voltage transmission cable manufacturing, extruders ensure the sheaths have high insulation and UV resistance. In fiber optic cable production, sheaths must be thin, lightweight, and flexible to protect the fiber core. Their technological advantages lie in high-precision extrusion control. For example, a closed-loop feedback system can adjust the extrusion speed in real time to accommodate cables of varying diameters and complex structures, thereby improving production efficiency and product consistency. With the rise of renewable energy and 5G technology, sheath extruders are driving the industry towards lightweight and environmentally friendly manufacturing. Gemwell Electrical Technology supports these innovative applications with its equipment. Combined with lifetime service support, customers receive ongoing upgrade recommendations as they expand into new areas, ensuring their machines remain future-proof.

4. Why is maintenance and calibration of wire and cable sheath extrusion machines so crucial? What are common failure points?

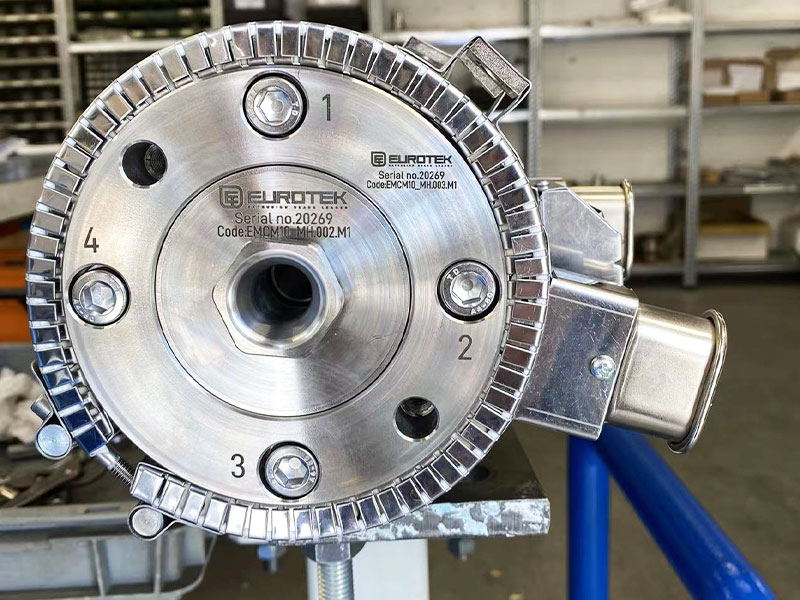

Extruder maintenance and calibration are key to ensuring long-term, efficient operation. Screw wear, aging heating elements, or control system deviations can lead to production defects such as uneven sheath thickness or unstable extrusion rate. Common failure points include metal fatigue in the screw and barrel, temperature sensor failure, and die blockage. If not addressed promptly, these issues not only increase scrap rates but can also cause safety incidents. Regular calibration involves pressure testing, temperature calibration, and screw cleaning to maintain extrusion accuracy. Gemwell Electric Technology emphasizes the core value of its Gemwell service: through a 24-hour rapid response mechanism, customers receive immediate on-site or remote assistance in the event of a failure, avoiding costly downtime. In addition, a one-year quality warranty covers all critical components, ensuring maintenance costs are manageable.

5. What technical and service factors should be considered when selecting a wire and cable sheath extrusion machine supplier?

Supplier selection requires a comprehensive evaluation of the machine's technical parameters (such as extrusion accuracy, energy efficiency, and automation level) as well as its after-sales support system. Technical factors include whether the screw design optimizes material flow and whether the control system supports multi-stage temperature control. Service factors emphasize response speed, training resources, and long-term support. For example, high-capacity environments require suppliers to provide rapid spare parts supply and preventive maintenance plans. Gemwell Electrical Technology stands out with its professional team and Gemwell promise: any operational questions are resolved within 24 hours, a one-year warranty ensures defect-free operation of new machines, and lifetime service support covers the entire life cycle of the equipment, from installation and commissioning to technical upgrades, providing customers with seamless solutions. This not only reduces total cost of ownership but also helps customers maintain their advantage in a highly competitive market.