| Main technical parameters |

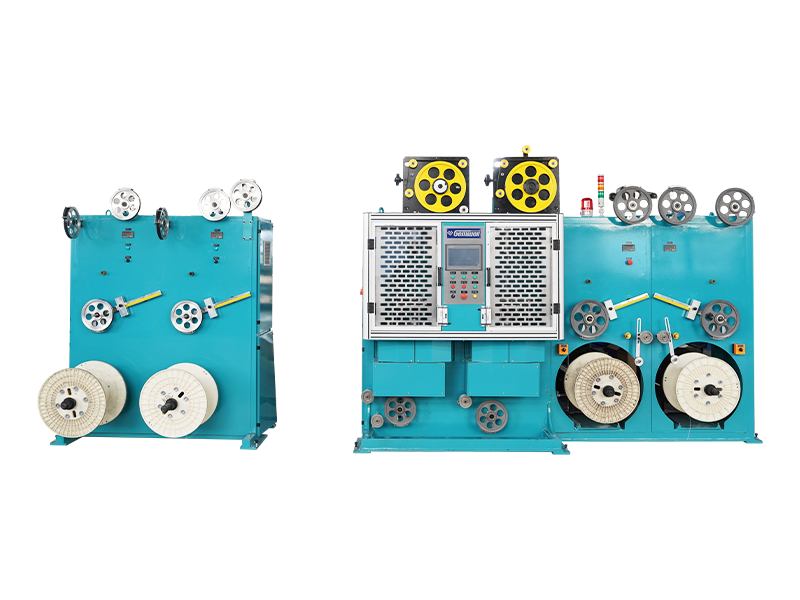

800 type |

1000 type |

| Suitable wire type |

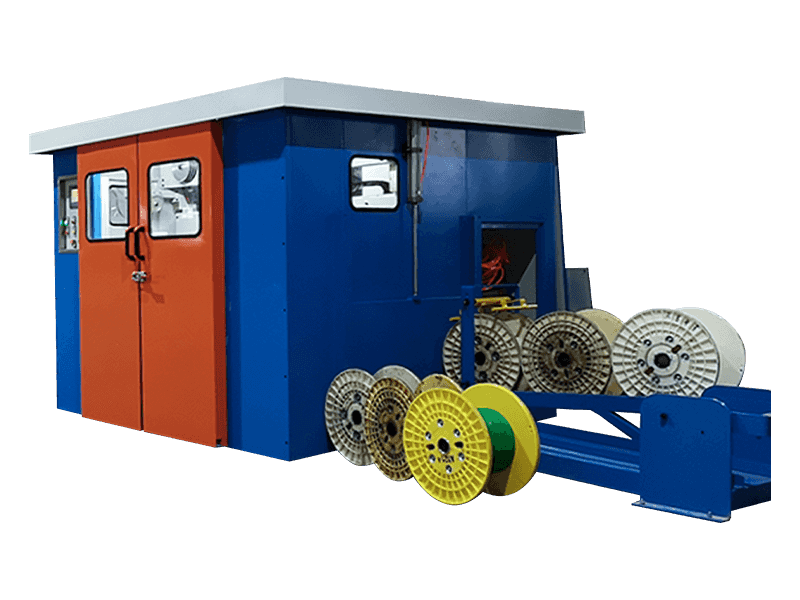

Mainly suitable for UTP, FTP and other multi core wires stranded cable, also for small-size high-frequency wire, drag chain wire, control cable and other cable stranding. |

| Core wire specification |

Ø1.5-3.0 |

| Outer diameter of stranded wire |

Ø4-9 |

| Pay-off specifications |

400-500 |

400-630 |

| Pay-off type |

It can be configured with various power or passive pay-off stands such as shaft type, shaftless type, back twist type, etc |

| Take-up specifications |

800x600 |

1000x750 |

| Inner hole of coil |

Ø80 |

Ø127 |

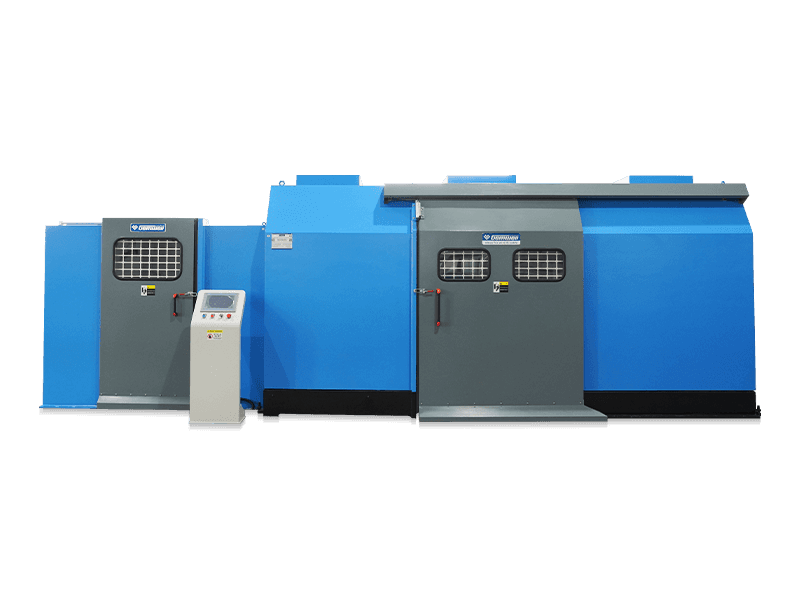

| Overall machine structure |

Take the center line of single twist main model as an axis, the production line from pay-off to take-up is linearly distributed in split type structure. |

| Stranding die |

The mold is fixed at the mold hole behind the wire concentrator, with a standard mold outer diameter of 25. |

| Back twist method |

The standard configuration does not have a back-twist function, but a back-twist pay-off can be customized to achieve torsion free and flexibility during cabling. |

| Back twisting ratio |

The standard configuration does not have a back twist ratio and the product has internal stresses. A back-twist pay-off can be customized with a back-twist ratio ranging from 0% to 120% |

| Stranding direction |

S/Z |

| Single twisting machine rotation speed |

MAX800RPM |

MAX700RPM |

| Wire-speed range |

30-150 |

| Wire twisted pitch |

50-300 |

| Pitch accuracy |

When operating at a constant speed, the pitch accuracy is within ±1.5mm. During the start/stop process, the pitch accuracy is within ±3mm. |

| Cantilever material |

Lightweight and low air resistance aluminum alloy cylindrical spiral arm structure. |

| Cantilever power |

30KW |

45KW |

| Main engine brake |

Hydraulic disc brake |

| Capstan type |

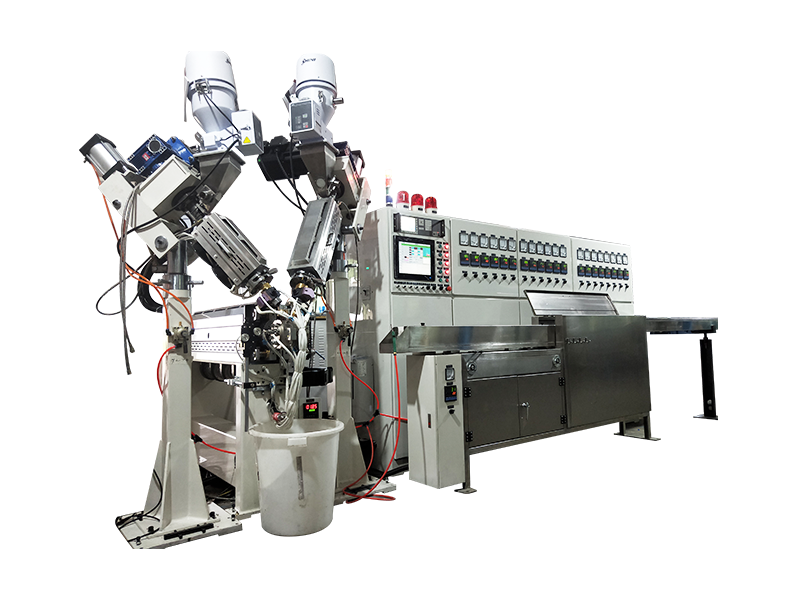

Single-groove double-wheel capstan.The rotating body and the mainframe wire spindle are directly connected through the tyre flexible coupling. The capstan wheel is a fixed wheel, and the external motor power drives the rotation of the capstan wheel through the mechanical structure. The driven wheel is a free wheel, capable of linear reciprocating motion. The external servo motor transmits constant tension to the driven wheel through mechanical transmission. |

| Capstan wheel diameter |

Ø320 |

| Capstan power |

7.5KW |

| Driven wheel tension motor |

3.7KW servo motor |

| Host reel lifting |

Hydraulic pallet electric lifting |

| Reel tightening method |

Top cone nut tightening take-up reel |

| Reel Loading weight |

MAX600KG |

MAX1000KG |

| Take-up reel power |

30KW |

45KW |

| Take-up wire position arrangement |

1.5KW |

| Pay-off material run-out detection |

Alarm and automatic stop when the core wire is about to run out/alarm and automatic stop when the wire is broken. |

| Pay-off tension type |

The standard is to adjust the tension by moving or adding/removing weight blocks, and it can also be customized to adjust the tension by using a servo motor. |

| Take-up tension type |

The driven wheel of the rotary capstan and the tension servo motor generate tension through the belt transmission. The driven wheel outputs a voltage signal when pulled by the wire displacement and controls and sends feedback of the PID speed of the take-up motor. |

| Taping material |

AL, MYLAR, Cotton tape, Non-woven fabric |

| The outer diameter of a tape reel |

MAXØ400 |

| Tape width |

5-35mm |

| Hole of the tape reel |

50.8/76 Universal |

| Taping power |

2.2KW |

| Taping speed |

MAX1800RPM |

| Taping tension units |

Standard to use magnetic powder clutch, hysteresis clutch can be customized. |

| Taping strip storage length |

400mm, strip change without cutting the wire. |

| Strip breakage inspection |

Automatic stop when the strip is about to be exhausted and broken |

| Overlap rate |

0-50%, programme setting |

| Longitudinal taping tension units |

Standard to use magnetic powder clutch, hysteresis clutch can be customized. |

| Longitudinal taping mould |

Seam wrapping tubes other types can be customized. |

| Tension display |

Standard is without tension display. Communication type digital pressure sensor, tension overrun alarm, and automatic shutdown can be customized. |

| Formula management |

A custom formulation management system enables data such as tension, temperature, extrinsic diameter, pitch, S/Z, line winding distance, and barometric pressure to be fed into the PLC, supporting data collection and import for digital production. |

| Safety protection |

Automatic detection and prediction of temperature /vibration /noise /pressure can be customized according to CE/CSA/UL standard design. |

| Spark detection |

Spark tester can be customized. |

| Power standards |

Standard is 3-phase 380V/50Hz and the power supply can be customised for different countries and regions. |

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

2026-02-16

2026-02-16 Webmaster

Webmaster