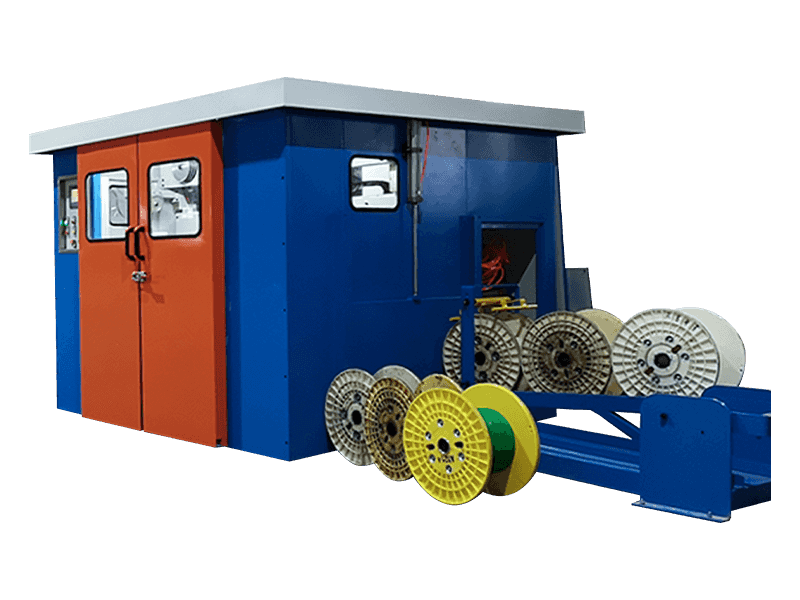

| Pay-off structure |

One head of the portal cradle shaftless active pay-off inside the stranding bow + One head of shaftless active pay-off outside the stranding bow |

| Take-up structure |

Horizontal portal cradle shaftless take-up, stranding bow double pitch pair twisting. |

| Overall machine structure |

Integrated upper and lower structure. Gantry crable shaftless active pay-off is placed on the top part of the inteagted machine. The shafless active pay-off is placed on the right part. The stranding take-up is placed on the bottom part of the integrated machine. |

| Suitable wire type |

Mainly used for LAN CABLE CAT5, CAT5E, CAT6A, etc.. |

| Core wire specification |

Range:Ø0.6-1.2mm, beyond this range, can be customized |

| Outer diameter of stranded wire |

range:Ø1.2-2.5mm, beyond this range can be customized. |

| Stranding die |

The standard mould OD size is 25 |

| Back twist method |

Achieve the twisting or pre-twisting, twisting means that the bows of the payoff machine and the twist pair rotate in opposite directions; pre-twisting refers to the same rotating direction of the payoff machine and pair twist, and can be selected on the touch screen. |

| Twisting/pre-twisting ratio |

0-100%, continuously and steplessly adjustable, set on the touch screen, PLC automatic control, automatic tracking of twisting/back twisting speed. At a twist rate of 33 percent, a single pitch is formed at pay-off, while two pitches are formed at take-off. Therefore, the total number of pitches is three. |

| Stranding direction |

S/Z |

| Pay-off rotation speed |

MAX1800 RPM (no load).

The actual startup speed is set according to the requirements of different wire grades. |

| Take-up rotation speed |

MAX1800RPM/5400TPM (no load).

The actual startup speed is set according to the requirements of different wire grades. |

| Wire-speed range |

The formula for calculating line speed: Bow-twister speed x 3 x pitch / 1000 = m/min. The maximum speed limit is 100 m/min. |

| Wire twisted pitch |

Optimal range:5.0-30.0mm, accurate to one decimal place, with a continuously adjustable level, selectable on the touchscreen. |

| Pitch accuracy |

Pitch accuracy ±0.3mm during fixed speed production, ±0.5mm during start-up/shutdown. |

| Stranding bow material |

The standard material used is a 65Mn steel strip with ceramic eyelets, which can be customized to a carbon fiber lightweight bow. |

| Pay-off bow power |

The standard configuration is a 5.5KW inverter motor that can also be customized for servo motors. |

| Take-up bow power |

The standard configuration is a 5.5KW inverter motor, which can also be customized for servo motors. |

| Stranding bow braking |

Electromagnetic brakes |

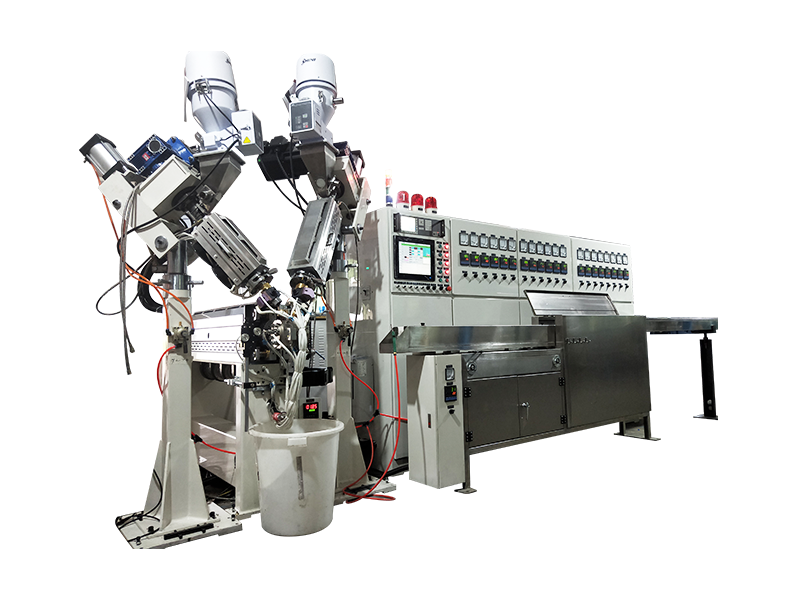

| Capstan type |

A double-wheel capstan is built into the portal cradle to take up |

| Capstan wheel diameter |

Ø185, 5-groove rubber-coated aluminium capstan roller + 5-groove split aluminium driven roller. |

| Capstan power |

The standard configuration is a 1.5KW inverter motor, which can also be customized for a servo motor. |

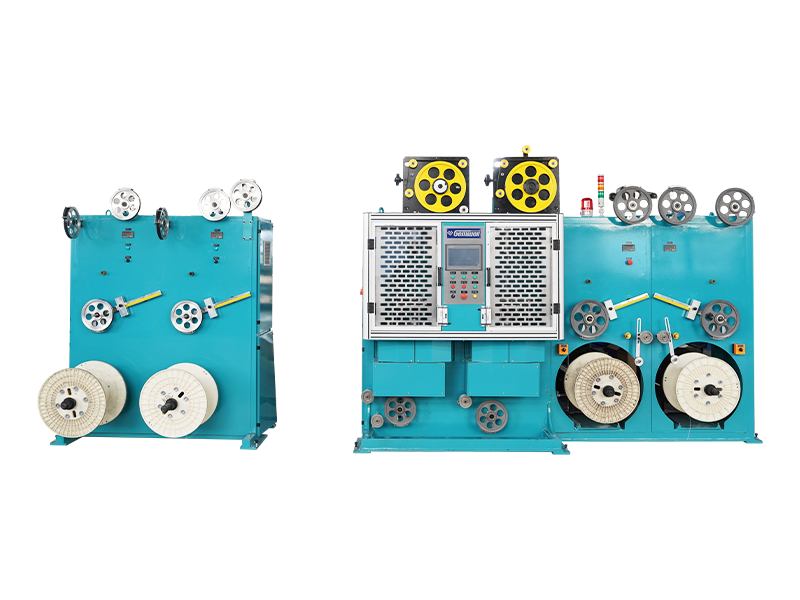

| Pay-off specification |

Ø500 ABS tool wheels. |

| Take-up specification |

Ø500 ABS tool wheels. 630 take-up wheels can be customized. |

| The inner hole of the reel |

The standard is Ø56mm, other sizes can be customized. |

| Reel Spindle lifting |

Electric lifting, skateboard loading, and unloading spool. |

| Reel tightening method |

Powerful elastic cylinder assembly tightening spool, tightening force>200KG, with self-locking protection, pneumatic release spool |

| Reel Loading weight |

MAX300KG |

| Pay-off reel power |

The standard configuration is a 2-0.75KW gear reducer motor, which also can be customized for a servo motor. |

| Take-up reel power |

The standard configuration is a 0.75KW gear reducer motor, which also can be customized for a servo motor. |

| Take-up wire position arrangement |

The standard is 30 polished rod traverse shaft units, which can be customized for servo motion controller rows. |

| Pay-off material run-out detection |

Alarm and automatic stop when the core wire is about to run out/alarm and automatic stop when the wire is broken. |

| Tension-type |

The standard is to adjust the tension by moving or adding balancing weights, PID controls the speed of pay-off or take-up or customizes it to adjust the tension with a servo motor. |

| Pay-off tension range |

3N-30N/0.3kg-3kg/300g-3000g |

| Take-up tension range |

5N-50N/0.5kg-5kg/500g-5000g |

| Tension accuracy |

±25g |

| Tension display |

Communication type digital display pressure sensor, tension overrun alarm, and automatic shutdown. |

| Formula management |

A custom formulation management system enables data such as tension, temperature, extrinsic diameter, pitch, S/Z, wire winding distance, and barometric pressure to be fed into the PLC, supporting data collection and import for digital production. |

| Safety protection |

Automatic detection and prediction of temperature /vibration /noise /pressure can be customized according to CE/CSA/UL standard design. |

| Spark detection |

Can be customized to add a spark tester |

| Power Standards |

The standard is 3-phase 380V/50Hz and the power supply can be customized for different countries and regions. |

| Intelligent software |

Customisable to add "the best production speed automatic matching function" software, to achieve production efficiency and product quality at the same time. |

| Core wire over-oil device |

A core wire oiling device can be customed and added. The insulating core wire is coated with a volatile lubricating oil to reduce friction during wire pair twisting. |

E-mail: info@gem-cablesolution.com

E-mail: info@gem-cablesolution.com Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China.

Address: No.8 Yuefeng Rd, High Tech Zone, Dongtai, Jiangsu, China | No.109 Qilin East Rd, Daning, Humen, Dongguan, Guangdong, China. English

English  English

English русский

русский 日本語

日本語 Español

Español عربى

عربى 中文简体

中文简体

2026-02-16

2026-02-16 Webmaster

Webmaster