Product Category

Product Category

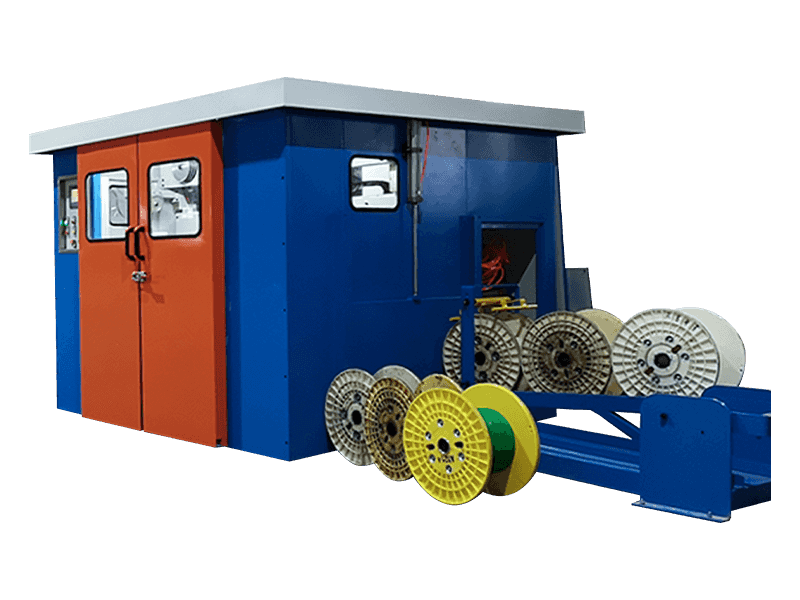

Core wire insulation extrusion is to cover the surface of the conductor with an insulating layer to insulate the conductor. According to the temperature level of the insulation material, it is divided into low-temperature extrusion and high-temperature extrusion; according to the density of the insulation layer, it is divided into solid extrusion and foam extrusion, and foam extrusion is divided into physical foaming and chemical foaming. According to the different solidization processes of the insulation layer, it is divided into water tank cooling molding and high-temperature drying tunnel cross-linking molding; According to the environmental protection level of the insulation layer, it is divided into environmentally friendly non-toxic material extrusion and non-environmental material extrusion; According to the insulation layer The fire-resistant and flame-retardant grades are different, which are divided into low smoke zero halogen flame-retardant extrusion and flammable material extrusion; according to different wire application fields, they are divided into electronic wire extrusion and signal wire extrusion; according to the extruder production line speed range is different, it is divided into the high-speed extrusion and low-speed extrusion.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

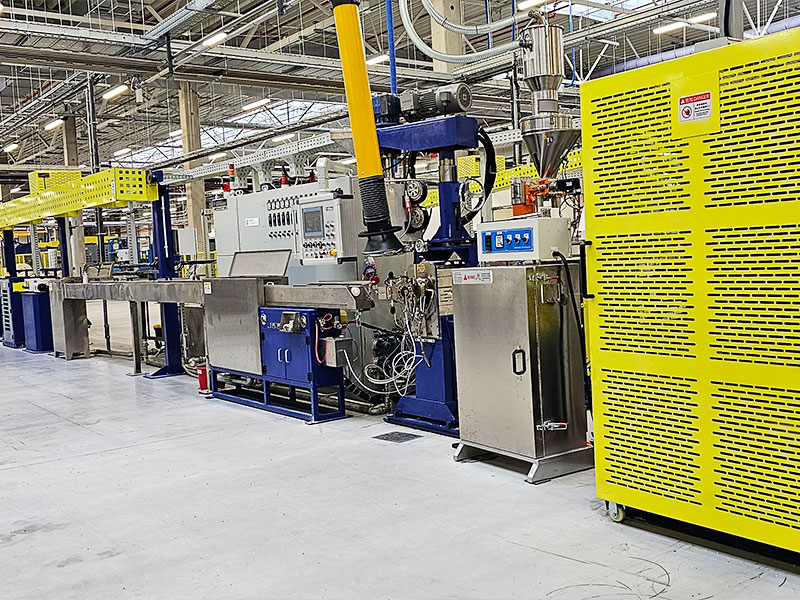

In the wire and cable manufacturing industry, cable extrusion machines are core equipment. Their technological sophistication and widespread application directly impact the efficiency and quality of the global supply chain. As a professional wire and cable equipment solutions provider founded in 2005, Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) leverages its extensive experience and service experience in over 40 countries worldwide (including the United States, Canada, Germany, and India). Adhering to the motto "Customer success is our goal," Gemwell is committed to driving industry progress through innovative design, reliable manufacturing, and customized support.

Q1: What is the basic definition of a cable extrusion machine? How has it become a core piece of equipment in wire and cable manufacturing?

A cable extrusion machine is an industrial machine specifically designed for melting, plasticizing, and extruding plastic or rubber materials. Its core function is to transform polymer raw materials (such as PVC, PE, or XLPE) through high temperature and high pressure into a continuous, uniform insulation layer or jacket, which is then applied to conductors (such as copper or aluminum wire) to create wire and cable products of various specifications. Key to this process is precise control of temperature, pressure, and extrusion speed to ensure consistent electrical properties and mechanical strength in the final product. In the global wire and cable industry, cable extrusion machines are not only the heart of the production process but also the cornerstone for improving efficiency and reliability. As an industry leader, Gemwell Electrical Technology (Jiangsu) Co., Ltd. has been dedicated to the research, development, and optimization of this type of equipment since 2005. Through its international design team, Gemwell has helped global customers, such as manufacturers in Germany and Mexico, solve extrusion challenges under complex conditions, ensuring stable operation at high outputs. This not only demonstrates the technical essence of this equipment but also highlights how specialized suppliers like Gemwell, leveraging their accumulated knowledge, translate theoretical knowledge into practical solutions to achieve precise forming and mass production of cable products.

Q2: What are the key steps involved in the operating principle of a cable extrusion machine? How do these steps affect the quality of the final product?

The operating principle of a cable extrusion machine is primarily divided into three sequential stages: raw material delivery, melt plasticization, and extrusion. First, polymer pellets are fed into the machine via a feeding system (such as a screw feeder). Next, within the heated barrel, the screw's rotation generates shear heat and external heating, melting the material into a uniform fluid. Finally, the melt is extruded through a precision die to form the desired insulation layer or jacket, where it rapidly solidifies in a cooling system. Quality control at each step is crucial. For example, screw design directly affects melt uniformity, die accuracy determines insulation thickness tolerance, and cooling rate impacts the product's mechanical durability and electrical properties. Temperature fluctuations or unstable pressures can lead to bubbles, uneven thickness, and even insulation defects, compromising the cable's withstand voltage performance and service life. Gemwell Electrical Technology (Jiangsu) Co., Ltd. deeply understands the fundamental challenges of these mechanisms when designing its cable extrusion machine solutions. Through advanced thermodynamic modeling and material rheology analysis, Gemwell optimizes screw geometry and temperature zoning. This enables Gemwell equipment to maintain high reliability in diverse global production environments, such as India's tropical climate or Russia's freezing temperatures, helping customers, such as cable manufacturers in Italy, reduce scrap and improve output quality. This in-depth knowledge, combining theory and practice, is the core strength of Gemwell Electrical Technology.

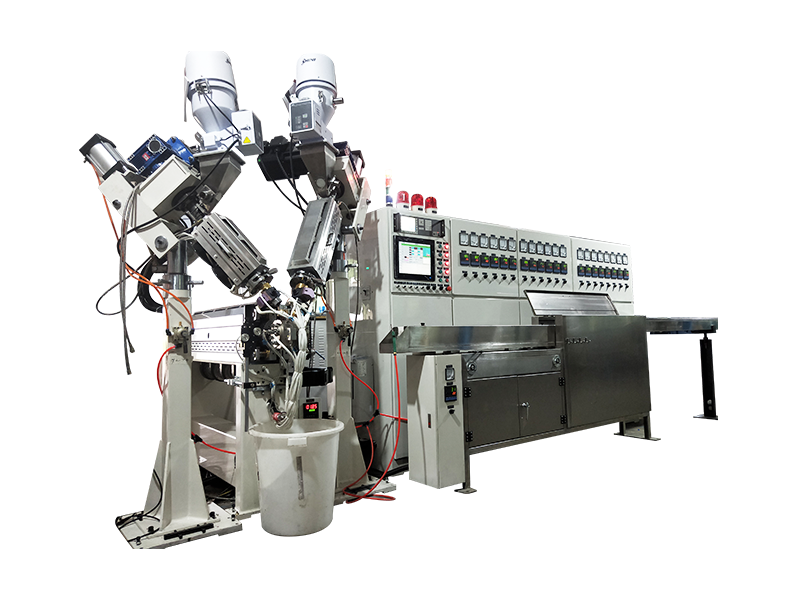

Q3: What are the main components of a cable extrusion machine? What engineering considerations should be taken into account when designing each component?

A cable extrusion machine consists of several key subsystems, including the feeding device, extrusion screw, heating and cooling systems, die head, traction device, and control system. The feeding device ensures a continuous supply of raw materials, and its design must consider material flow properties (such as moisture content or particle size) to avoid blockage. The extrusion screw is a core component, typically divided into a feed section, a compression section, and a metering section. The geometric parameters of each section (such as the L/D ratio and screw groove depth) directly affect melting efficiency and mixing uniformity. Engineering requires a balance between shear force and heat conduction to prevent material degradation. The heating and cooling system uses zoned control to precisely manage temperature gradients (for example, low temperature in the feed zone and high temperature in the compression zone) to maintain material rheological properties. The die head is responsible for forming the material, and its aperture and flow channel design must be matched to the cable specifications to avoid stress concentration. The pulling device provides continuous pulling force to ensure synchronization between extrusion speed and cooling. Finally, modern PLC or HMI control systems integrate sensors to monitor parameters in real time and automatically adjust them. The coordinated operation of these components requires a highly modular and scalable design to accommodate different cable types (such as high-voltage power cables or data communication cables). When manufacturing equipment, Gemwell Electrical Technology (Jiangsu) Co., Ltd. incorporates these engineering considerations into its overall approach. For example, through its global R&D network (serving customers in Thailand and the United States), it customizes screw materials (such as nitrided steel) for enhanced wear resistance, or optimizes control system algorithms to minimize energy consumption. Gemwell's solutions not only deepen component knowledge but also demonstrate how system integration can address practical bottlenecks faced by customers in diverse production scenarios.

Q4: Why are cable extrusion machines considered an indispensable link in the wire and cable manufacturing process? How does their efficiency impact the overall industry chain?

cable extrusion machines serve as the "molding engine" in the manufacturing chain, as the extrusion process of insulation and jacketing determines the cable's core performance indicators, such as insulation resistance, weather resistance, and fire rating. Without efficient extrusion, the conductors cannot be uniformly protected, potentially leading to failures such as short circuits, overheating, or signal interference. Specifically, extrusion efficiency (measured in meters per minute) directly impacts production capacity and costs: high-speed extrusion can shorten cycle times, but this must be balanced with quality (for example, avoiding embrittlement caused by excessive cooling); conversely, low-speed extrusion improves precision but can increase energy consumption. Optimizing this process directly impacts the reliability of downstream applications, such as building wiring, automotive wiring harnesses, or submarine cables. Within the global supply chain, as demand grows (for example, driven by renewable energy projects for high-voltage cables), extruder efficiency has become a key competitive focus. Gemwell Electrical Technology (Jiangsu) Co., Ltd. has a deep understanding of this key point and, leveraging its international service experience (covering automotive cable plants in Mexico and energy projects in Canada), provides clients with energy-efficiency-oriented designs. For example, Gemwell's equipment utilizes variable frequency drives and heat recovery systems to reduce energy consumption by over 20%. Its modular design enables rapid die changeovers, helping clients (such as OEMs in India) cope with order fluctuations. This strategy of transforming efficiency knowledge into practical value embodies Gemwell Electrical Technology's commitment to customer success.

Q5: What are the main application areas for cable extrusion machines in modern industry? How do these applications drive technological innovation?

cable extrusion machines have a wide range of applications, encompassing power transmission (such as high-voltage transmission cables), communications (such as optical fiber jacketing), construction (such as fire-resistant cables), automotive (such as wiring harness insulation), and emerging industries (such as cables for charging stations for new energy vehicles). Each sector places distinct demands on extrusion: power cables require thick insulation to withstand high voltages, communications cables require thin, uniform jackets to ensure signal integrity, and automotive cables emphasize flexibility and temperature resistance. These differentiated demands are driving technological innovation, such as the development of multi-layer co-extrusion technology (simultaneously extruding different materials) to enhance functional integration, or the introduction of nanocomposites to enhance flame retardancy. Technological advancements also include automation upgrades, such as online monitoring systems that detect thickness deviations in real time, reducing manual intervention. In its global practice (serving Industry 4.0 factories in Germany and infrastructure projects in Thailand), Gemwell Electrical Technology (Jiangsu) Co., Ltd. has deeply integrated this application knowledge with customer needs, providing customized solutions (such as low-temperature adaptability for Russia's harsh climate) to promote the intelligence and versatility of its extruders. Gemwell's involvement not only expands the boundaries of equipment knowledge but also helps customers (such as US technology companies) seize opportunities in emerging fields.

Q6: What are the technological trends in cable extrusion machines? How do global market dynamics influence these innovations?

Current technological trends focus on intelligence, greenness, and high performance. Intelligence is reflected in AI-driven predictive maintenance systems that use big data to analyze screw wear or temperature anomalies to avoid downtime. Greenness involves the use of environmentally friendly materials (such as halogen-free flame retardants) and energy optimization to comply with global regulations (such as EU RoHS). High performance includes high-speed extrusion (>1000m/min) and precision control to meet the stringent requirements of 5G and electric vehicles. Global market dynamics, such as supply chain localization (re-shoring of manufacturing in the US) or the growth of emerging economies (industrialization in India), are accelerating these innovations and driving the evolution of extruders toward modular and compact designs. As an international supplier, Gemwell Electrical Technology (Jiangsu) Co., Ltd. is actively integrating these trends through its cross-continental R&D efforts (such as the Italian collaboration project) to develop adaptive control systems and sustainable solutions. Gemwell's accumulated knowledge ensures its equipment provides forward-thinking support in volatile markets, such as Mexico's automotive industry transformation, helping customers achieve technological upgrades.

Q7: Why does choosing a specialized supplier like Gemwell Electric Technology significantly improve the operational efficiency of cable extrusion machines?

The value of a specialized supplier lies in transforming deep technical knowledge into reliable equipment: they understand key extruder parameters (such as melt index matching) and failure modes (such as screw wear mechanisms) and can provide comprehensive support (design, installation, and training). Gemwell Electric Technology (Jiangsu) Co., Ltd.'s strength stems from its global experience (serving over 40 countries since 2005). For example, through its localized service team, it can quickly respond to customers (such as urgent maintenance needs in Canada) to ensure continued equipment efficiency. Gemwell's customer success focus means knowledge sharing and customized optimization to help users maximize their return on investment.

Q8: How does Gemwell Electric Technology's knowledge base of cable extrusion machines align with its mission to drive industry progress?

cable extrusion machine knowledge encompasses materials science, mechanical engineering, and control theory. Its essence lies in ensuring cable performance through precision engineering. With customer success as its goal, Gemwell Electrical Technology (Jiangsu) Co., Ltd. integrates this knowledge into global practices and drives innovative solutions. This synergy not only improves equipment efficiency but also strengthens the resilience of the entire supply chain. As demonstrated by Gemwell projects in India and Russia, knowledge-driven development is the core engine of sustainable growth.