Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

Q: What is the core concept of a foamed wire insulation extrusion line?

A: A foamed wire insulation extrusion line is an industrial system specifically designed for wire and cable manufacturing. Its core principle is to infuse a polymer material (such as polyethylene or polyvinyl chloride) with a foaming agent through an extrusion process to form a microporous insulation layer. This process involves melting the material, mixing the foaming agent, precisely extruding it, and cooling it to form a final shape. The result is a lightweight, highly insulating foam structure on the conductor surface. The key to this technology is controlling the foaming ratio (typically 30%-50%) to optimize electrical performance and mechanical strength. Gemwell Electrical Technology emphasizes rigorous design, ensuring that every step adheres to material science principles to avoid ineffective foaming or delamination defects, thus providing customers with a zero-defect foundation.

Q: How does a foamed wire insulation extrusion line work to ensure uniform and reliable insulation?

A: The operating principle begins with a metered feeding system for the polymer raw material. The material is melted through a twin-screw extruder and then injected with a chemical foaming agent (such as azodicarbonamide). High pressure and high temperature induce gas release, forming uniform micropores. The melt is then extruded through a precisely designed die, wrapped around the conductor, and solidified in a water bath or air cooling process. The entire process relies on real-time closed-loop feedback from temperature, pressure, and control systems to prevent uneven bubbles or density fluctuations. For example, in its rigorous manufacturing, Gemwell Electrical Technology uses advanced sensors and algorithms to optimize parameter settings, ensuring that insulation thickness tolerances are controlled to micron levels. This directly improves the cable's voltage resistance and service life, demonstrating the contribution of strict quality control to reliability.

Q: Why is foam insulation technology superior to traditional solid insulation in wire applications?

A: The core advantages of foam insulation lie in the physical properties of its microporous structure: lightweight (reducing overall cable weight by 20%-30%), high dielectric strength (dielectric constant reduced to 1.5-2.5), and excellent flexibility and thermal stability. These properties are achieved through a precise foaming ratio, effectively reducing signal attenuation and making it suitable for high-frequency communication cables (such as 5G or data center cabling). Traditional solid insulation is prone to material waste and electrical performance bottlenecks, while foam technology optimizes resource efficiency through innovation. Gemwell Electrical Technology continuously innovates to create value for its customers. For example, it develops low-foaming agent residual formulas to avoid environmental hazards and ensure zero-defect performance in harsh environments.

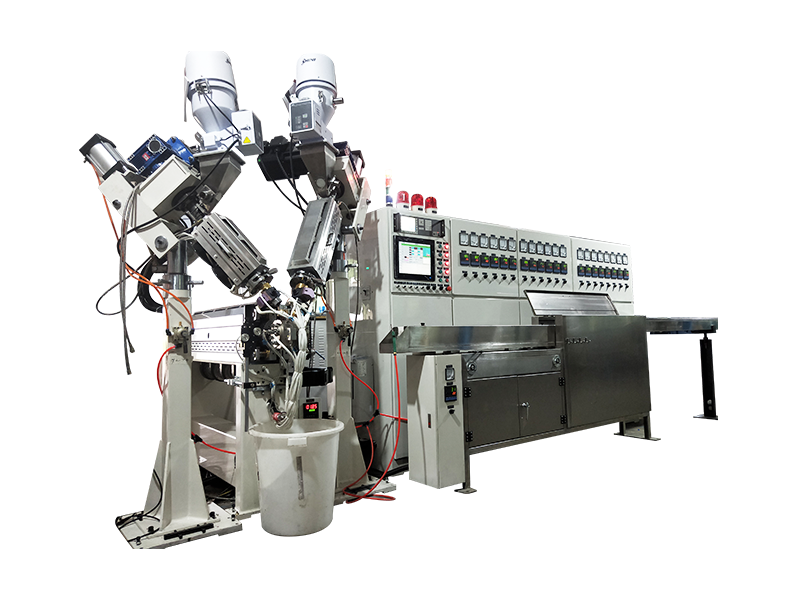

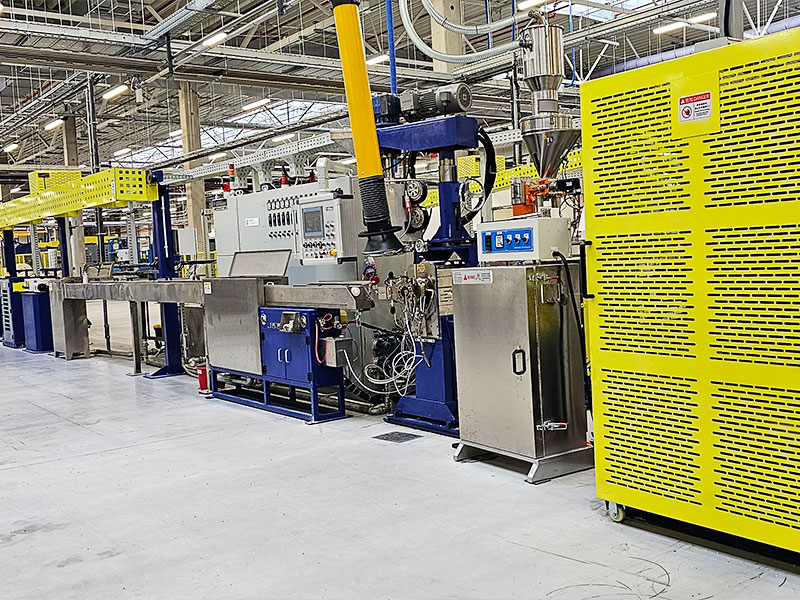

Q: How do the key components of a foam extrusion line work together to achieve efficient production?

A: The line consists of five main components: a feeding system (precisely metering polymer and foaming agent), an extruder (a twin-screw design ensures uniform mixing), a foaming die (customized geometry controls cell distribution), a cooling system (staged cooling to avoid thermal stress and deformation), and a take-up device (tension control ensures cable flatness). These components are interconnected via an integrated control system (such as a PLC or SCADA system) that monitors variables such as melt flow index and foam density in real time. Through rigorous design, Gemwell Electrical Technology optimizes component compatibility, such as by selecting corrosion-resistant materials and implementing redundant mechanisms, to reduce failure rates and ensure zero-defect shipments. This synergy increases production capacity by 30% while reducing energy consumption by 20%, demonstrating industry-leading efficiency.

Q: How is the quality control process used to ensure the consistent quality of foam insulation extrusion products?

A: Quality consistency stems from a comprehensive quality control strategy, including upstream raw material testing (foaming agent purity analysis), process monitoring (online X-ray or ultrasonic testing for cell uniformity), and finished product testing (such as high-voltage breakdown testing and mechanical stretching). Key indicators, such as foam density, must be controlled within ±5% to prevent insulation perforation or electrical shorts. Gemwell Electrical Technology implements a rigorous quality control system that integrates automated visual inspection and statistical process control (SPC) to identify potential sources of variation and ensure zero defects in every batch. This not only reduces customer returns but also drives innovative product iterations through continuous data feedback, solidifying its industry leadership.

Q: How are innovative trends in foaming technology for wire insulation aligned with customer value?

A: Innovation trends focus on sustainability and intelligence. For example, developing bio-based blowing agents to replace traditional chemicals to reduce carbon footprint, or integrating AI for predictive maintenance to optimize extrusion parameters and improve yield. These advancements directly create customer value, such as reducing production costs by over 20% and complying with stringent environmental regulations (such as RoHS). Driven by innovation, Gemwell Electrical Technology has invested in the research and development of supercritical foaming technology, achieving nanoscale cell structures and enhancing cable signal transmission efficiency. Through rigorous design, the company commercializes these cutting-edge solutions, ensuring zero-defect, long-term reliability in shipped products, giving customers an edge in the competitive market.

Q: In Gemwell Electrical Technology's practice, how does rigorous manufacturing impact the lifecycle management of foam extrusion lines?

A: Rigorous manufacturing emphasizes full lifecycle optimization: from equipment material selection (using high-wear-resistant alloys to extend extruder life) to maintenance strategies (predictive maintenance to reduce downtime), ensuring line efficiency exceeding 90%. Gemwell Electrical Technology's modular design simplifies upgrade paths, such as compatibility with new blowing agents or high-speed extruder heads, allowing customers to flexibly respond to market demands. This rigorous approach not only reduces total cost of ownership (TCO), but also ensures over 10 years of trouble-free operation through strict quality control, fulfilling its zero-defect commitment. Ultimately, customer value is reflected in improved long-term return on investment, underscoring the company's commitment to continuously providing leading products.

Q: In which industries and applications does foam insulation extrusion production line demonstrate strategic importance?

A: This technology is essential in several strategic sectors: communications (high-speed data cables require low-loss foam insulation), automotive electronics (lightweight wiring harnesses improve energy efficiency), and new energy (photovoltaic cables require high weather resistance). The key to these applications lies in customized design, such as adjusting the foaming ratio to match specific frequency band requirements. Gemwell Electrical Technology supports these applications with innovative products. Rigorous design ensures the insulation layer maintains integrity under extreme temperatures and vibration, providing customers with reliable solutions. This directly drives industry advancements, such as 5G deployment and the widespread adoption of electric vehicles, demonstrating the synergistic value of technological innovation and rigorous quality control.