Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

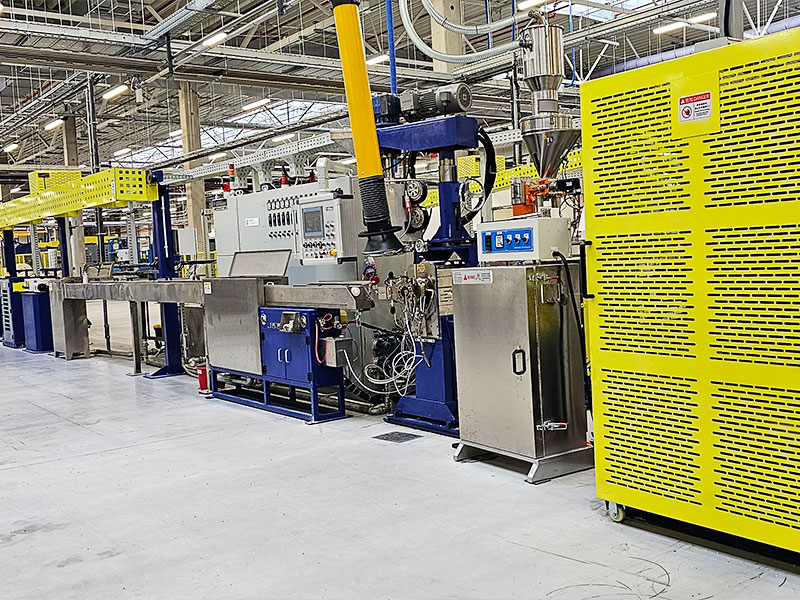

Q: What is the core functional objective of a high temperature wire insulation extrusion line?

A: Its core objective is to enable precise overmolding of specialty engineering polymers (such as cross-linked polyethylene (XLPE), polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), and silicone rubber) under high temperature conditions (typically 200°C to 400°C and above). The line must ensure the insulation layer has uniform thickness, a defect-free, dense structure, stable dielectric properties, and long-term thermal aging resistance. Serving high-end clients in sectors such as new energy and aerospace, Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) is particularly focused on the ability of this line to exploit the extreme performance of materials.

Q: What are the unique technical challenges of high temperature extrusion?

A: The key challenges focus on controlling material rheological behavior, managing the thermal history, and interfacial bonding strength:

high temperature melt rheology control: Specialty polymers experience a sharp drop in melt strength at high temperatures, making them susceptible to sag or cracking. Maintaining melt stability requires precise screw configuration design (such as barrier screws and optimized shear elements) and coordinated multi-temperature zone control (±1°C accuracy). Gemwell's extrusion system utilizes a modular temperature control strategy to specifically adapt to the viscosity-temperature sensitivity of different materials.

Mitigating Thermal Degradation Risks: High temperatures exacerbate material oxidation/decomposition. Solutions include a nitrogen protection system in the melt channel, ultra-short melt residence time design, and a high-efficiency vacuum degassing device. The Gemwell production line optimizes flow channels through fluid dynamics simulation, significantly reducing the formation of degradation byproducts.

Conductor-Insulation Bond Reliability: high temperature applications (such as motor winding wire) require that the insulation and conductor maintain a bond despite differences in thermal expansion coefficients. Inline plasma/flame treatment systems and specialized adhesive layer co-extrusion technology are core technology modules in Gemwell's integrated solution.

Q: How does the production line ensure the long-term reliability of high temperature insulated cables?

A: Reliability stems from closed-loop quality control throughout the entire process:

Online measurement and control systems: Laser outer diameter measuring instruments and X-ray eccentricity detectors provide real-time feedback on thickness deviations, and linked extruder speed control enables µ-level closed-loop control. Infrared thermal imaging cameras monitor cooling gradients to avoid internal stress concentrations.

Crosslinking process integration: For materials like XLPE, production lines must integrate high-pressure silane crosslinking (Sioplas) or electron irradiation (E-beam) units to precisely control the degree of crosslinking and increase the heat deflection temperature (HDT). Gemwell's tandem crosslinking system enables continuous production and avoids secondary processing damage.

Cooling process optimization: high temperature insulation layer cooling requires multi-stage gradient cooling water tanks (water temperature zones can be adjusted to ±0.5°C). Combined with turbulent flow design, this system suppresses micropore formation and ensures uniform crystal structure. Gemwell's cooling system consumes 30% less energy than traditional designs, aligning with its sustainability goals.

Q: How does high temperature insulation extrusion meet the industry's demand for sustainable development?

A: Sustainability is reflected in improved energy efficiency, reduced material consumption, and greener processes:

High-efficiency drive solutions: Permanent magnet synchronous motors (PMSMs) and servo control systems replace asynchronous motors, achieving energy savings of 25%-40%. Gemwell's production lines are equipped with energy recovery modules as standard, feeding braking energy back into the grid.

Micro-extrusion technology: Through high-precision gear pump metering and die flow optimization, insulation layer eccentricity is controlled to ≤3%, increasing material utilization to over 99.2% and reducing polymer waste.

Non-toxic process substitution: Perfluorooctanoic acid (PFOA) additives are eliminated from fluoropolymer processing, and environmentally friendly lubrication systems are adopted. Gemwell's R&D center has verified the industrial extrusion parameters for several bio-based high temperature polymers, promoting emission reduction at the source.

Q: What are the differentiated capabilities of Gemwell Electrical Technology in the high-end extrusion production line sector?

A: Its core competitiveness lies in its ability to customize technology based on a deep understanding of end-use scenarios:

Specialty Materials Database: We have accumulated rheological-process mapping models for over 100 high temperature polymers (including ceramic refractory materials and polyimide compounds), enabling precise prediction of processing windows.

Digital Twin System: Through extrusion process simulation, we can virtually debug process parameters, shortening customers' new formulation introduction cycles by over 50%.

Full Lifecycle Service: From conductor pay-off tension control to anti-sticking solutions for finished product rewinding, Gemwell provides a closed-loop technology offering, including corona resistance life testing and failure analysis, supporting customers in achieving stringent certifications such as UL 758 and IEC 60811.

Q: How does the evolution of high temperature insulation extrusion production lines align with industrial transformation?

A: Gemwell Electric Technology (Jiangsu) Co., Ltd. is advancing this technology towards ultra-high speeds (>2000 m/min), ultra-thin insulation (<50 µm), and multi-material co-extrusion, while simultaneously deepening carbon emission monitoring (ISO 14067) and green factory practices. Its production line has enabled clean energy scenarios such as wind power torsion-resistant cables, high-voltage wire harnesses for new energy vehicles, and heat-resistant cables for solar thermal power generation, demonstrating the deep compatibility of high-end equipment manufacturing and sustainable development goals.