Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

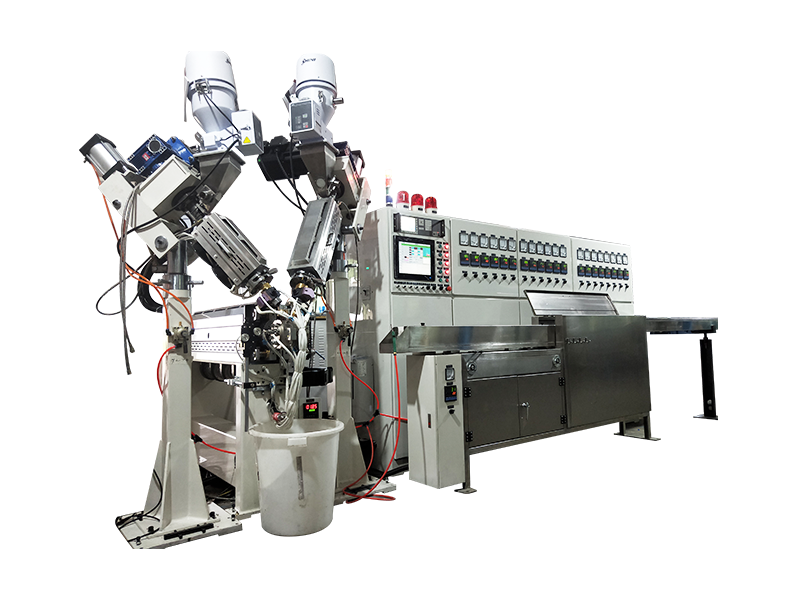

Q1: What defines the core value of the solid core wire insulation extrusion line?

A: This line uses molten polymer to form a continuous, uniform insulation layer on the conductor surface. Its core technology lies in achieving a dynamic balance between dielectric properties, mechanical strength, and production rate. Taking Gemwell's industrial practice as an example, its production line integrates material rheology control technology to ensure a stable insulation layer thickness tolerance within ±0.02mm, significantly exceeding the IEC 60227 standard requirement.

Q2: How does the extruder screw configuration affect insulation quality?

A: A barrier screw combined with a two-stage mixing section allows for precise control of the melt temperature profile. When processing XLPE (cross-linked polyethylene), Gemwell uses a 30:1 aspect ratio design, coupled with a shear heat optimization system, to achieve a melt temperature fluctuation of ≤±1.5°C, effectively preventing the surface sharkskin phenomenon caused by pre-crosslinking.

Q3: Why is conductor pretreatment critical to quality?

A: The oxide layer on the surface of copper conductors can cause electrical dendrites at the insulation interface. Gemwell's production lines are equipped with online electrolytic cleaning and an inert gas shielding system to keep the conductor's oxygen content below 5ppm. Laser diameter measurement provides real-time feedback on the conductor's ovality, ensuring insulation concentricity >98%.

Q4: What's the secret behind the ergonomic design of the cooling trough?

A: Gradient cooling technology is crucial. Taking PVC insulation as an example, Gemwell employs a three-stage cooling system: a first stage of 70°C water film cooling to eliminate internal stress, a second stage of 25°C turbulent cooling to set the shape, and a final stage of 15°C constant temperature to stabilize crystallinity, keeping the insulation's thermal shrinkage below 2%.

Q5: How does the online inspection system achieve zero-defect control?

A: It combines beta-ray thickness measurement (accuracy 0.001mm) with power-frequency spark testing (9kV/mm) and CCD visual inspection (50μm resolution). In Gemwell's intelligent production line, this data is connected to the MES system in real time, enabling traceability of process parameters for every meter of wire.

Q6: What technological advances have occurred in the cross-linking process?

A: Currently, the mainstream methods are silane warm water crosslinking (Sioplas) and electron irradiation crosslinking. Gemwell's Sioplas achieves a line speed of 300 m/min. Its quantum-level catalyst injection system stabilizes the crosslinking degree at 75%-85%, with a dielectric strength of 25 kV/mm.

Q7: What challenges does the application of new materials pose to production lines?

A: For example, TPE (thermoplastic elastomer) requires a screw compression ratio of 2.5:1 and precise control of the melt temperature at 170 ± 3°C. Gemwell's modular extrusion system enables complete switching between PP/PE/TPE materials within 2 hours, with a scrap rate of less than 0.8%.

Q8: How are energy-saving technologies integrated into modern production lines?

A: The focus is on energy recovery. Gemwell's production lines utilize permanent magnet synchronous motors (IE4 efficiency rating) and an extruder barrel waste heat recovery system, reducing energy consumption per ton of wire to 280 kWh, a 35% energy saving compared to traditional equipment.

Q9: How is tension control achieved during high-speed production?

A: We utilize a fully closed-loop servo traction system, with real-time torque adjustment via a coil diameter adaptive algorithm. In Gemwell's 0.5mm² cable production, tension fluctuations are controlled to ±0.2N at a line speed of 1200m/min, ensuring no slub deformation in the insulation layer.

Q10: Where will future technological breakthroughs lie?

A: We are focusing on online modification technology for nanocomposite insulation materials. Gemwell is developing an in-situ nano-Al₂O₃ dispersion system that can achieve filler dispersion >95% during the extrusion process, increasing the insulation material's temperature resistance to 150°C.

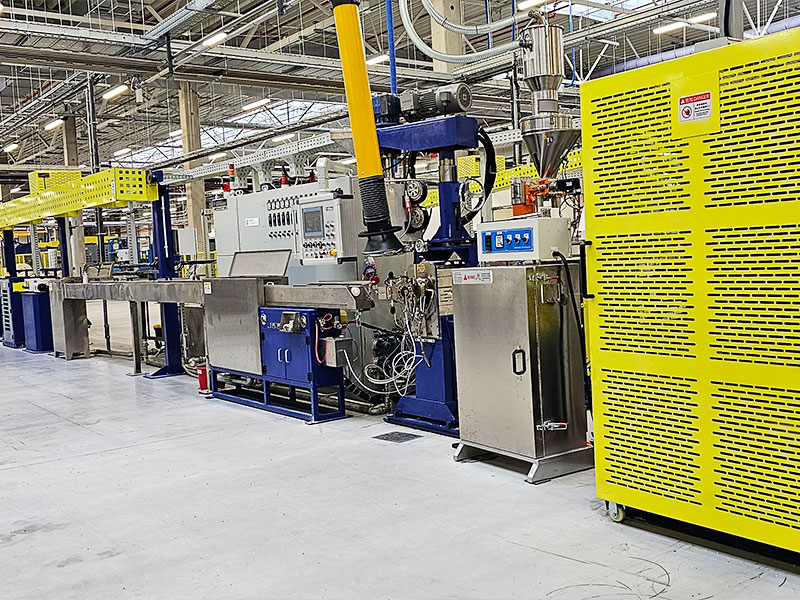

A fusion of industrial practice and technological philosophy

Gemwell engineers adhere to the principle of "thermal homogenization" during production line commissioning: from material plasticization to cooling and setting, every thermodynamic parameter must meet the time-temperature equivalence principle. This meticulous pursuit of process control has enabled its 105°C flame-retardant cables to pass the UL 758 2000-hour aging test.

While the industry is still discussing traditional three-layer co-extrusion technology, Gemwell has already achieved mass production of a five-layer nano-barrier insulation structure. This technology suppresses partial discharge to below 1pC. This is the engineering expression of the company's "Enterprise and Exploration" spirit—translating breakthroughs in materials science into exponential improvements in cable performance.

In the central control room of the Jiangsu production base, 200 sets of process parameters collected every microsecond are not only production data but also a digital reflection of the molecular chain arrangement in the insulation medium. This precise control of the microscopic world enables Gemwell's insulated cables to demonstrate astonishing performance consistency in environments ranging from the humid Brazilian rainforest to the scorching deserts of the Middle East, demonstrating the technological leap from "Made in China" to "Made in China with Precision."