Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

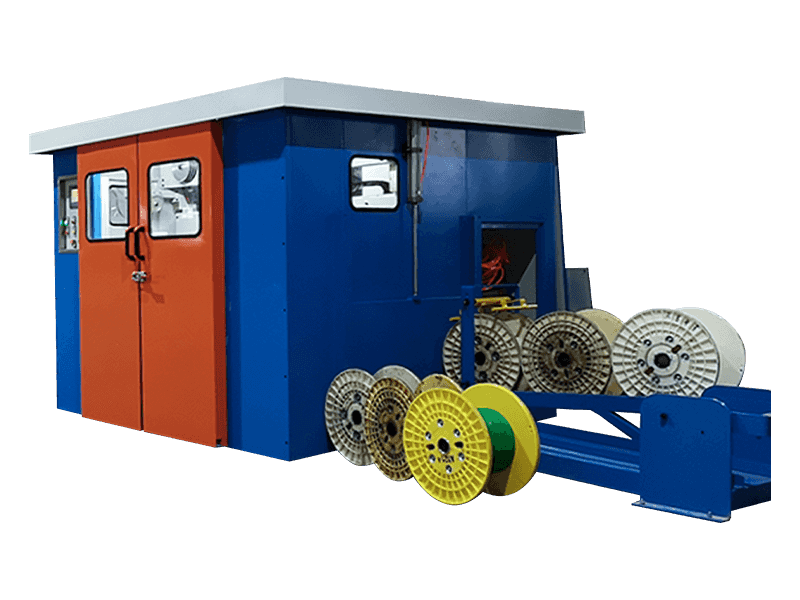

In today's high-speed information transmission landscape, network cable manufacturing technology is becoming increasingly sophisticated. back twist pair twisting machine for network cables, as key equipment, are driving breakthroughs in cable performance. Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) adheres to its vision of maintaining close partnerships with global manufacturers of high-end information transmission cables and wires. With continuous innovation at its core, Gemwell is committed to optimizing capacity utilization, improving product quality, and providing support in new product design and material processing.

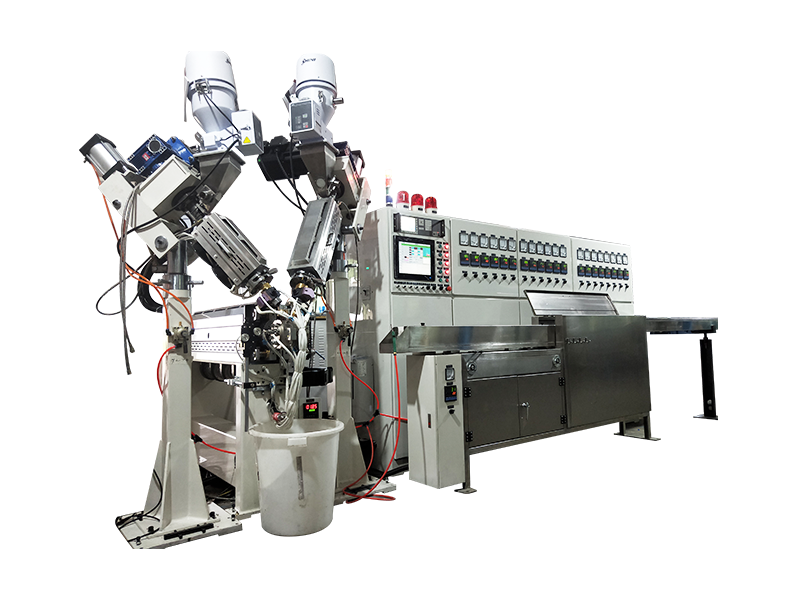

Q1: What is the basic operating principle of the back twist pair twisting machine for network cable? How does it play a key role in network cable manufacturing?

A1: The core of the back twist pair twisting machine for network cable lies in its unique twisting mechanism. This mechanism achieves uniform winding of twisted pairs by precisely controlling the reverse twisting process. Unlike traditional twisting methods, reverse twisting significantly reduces geometric asymmetry between conductors, thereby minimizing electromagnetic interference (EMI) and crosstalk during signal transmission. In network cable manufacturing, this technology ensures that copper wire pairs maintain stable impedance characteristics under high-frequency signals, providing the foundation for high-performance Ethernet cables such as Category 6 and Category 7. Through continuous innovation, Gemwell combines this mechanical principle with advanced control systems to help manufacturers optimize process parameters. For example, real-time tension monitoring and adaptive twisting algorithms ensure consistent electrical performance across mass production. This directly aligns with Gemwell's vision: to drive innovation and help partners improve product quality to meet the stringent requirements of high-speed data transmission.

Q2: Why is Back Twist technology so crucial in network cables? What are its significant advantages?

A2: Back Twist technology is crucial because it significantly impacts the cable's signal integrity. This technology offers three key advantages: First, it effectively balances the capacitance and inductance distribution between conductors through a reverse twisting motion, significantly reducing near-end crosstalk (NEXT) and far-end crosstalk (FEXT), which is crucial for high-frequency applications such as 10GbE networks. Second, this technology enhances the mechanical durability of the cable, reducing performance degradation during installation or flexing, ensuring long-term reliability. Third, it can accommodate a wide range of materials, such as high-purity copper or alloy conductors, improving the cable's bandwidth and transmission efficiency. Gemwell's involvement in this field is based on its innovation-focused business development strategy: through technological collaboration, the company helps customers transform these advantages into practical productivity. For example, Gemwell provides material processing support, helping manufacturers customize twisting parameters to match new composite materials, thereby achieving a leap in product quality while optimizing capacity utilization and reducing waste.

Q3: How does Gemwell drive industry innovation with its back twist pair twisting machine for network cable? What is unique about its partnership model?

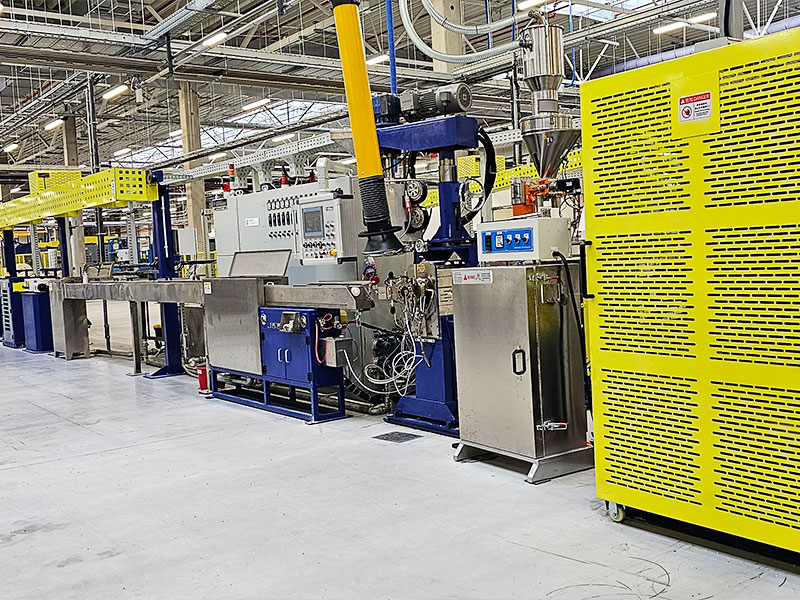

A3: Gemwell's involvement goes beyond simple equipment supply; rather, it drives innovation across the entire supply chain through deep partnerships. The company's role in the back twist pair twisting machine for network cable (BTM) is reflected in the integration of mechanical engineering and materials science. They develop intelligent feedback systems that adjust the twisting angle and speed in real time to accommodate varying cable specifications. They also support customers in integrating reverse twisting technology into new product designs to address the challenges of emerging applications such as 5G and IoT. This partnership model is unique in that Gemwell emphasizes collaborative R&D—sharing data insights with global manufacturers to jointly address technical bottlenecks, such as maintaining twisting accuracy in high-throughput production. This directly embodies Gemwell's vision: to help partners maximize capacity utilization through continuous innovation and ensure that every cable meets high-end transmission standards. For example, when processing new materials (such as low-smoke, halogen-free, and flame-retardant materials), Gemwell provides process optimization solutions to ensure that the reverse twisting process does not compromise environmental performance or signal quality.

Q4: How does the back twist pair twisting machine for network cable impact production line capacity utilization? How does Gemwell help customers achieve efficient optimization?

A4: This equipment impacts capacity utilization in multiple ways: its efficient twisting mechanism shortens process cycles and increases output per unit time. At the same time, its precise control reduces defective products, avoiding material waste and rework losses. In large-scale network cable production, this directly translates into higher OEE (Overall Equipment Effectiveness). Gemwell's contribution to this lies in its customer support system. Through innovative design and data analysis, the company helps manufacturers calibrate equipment parameters, such as optimizing twisting speed and tension settings, to match the throughput requirements of specific production lines. This not only improves utilization but also ensures consistent product quality. In line with Gemwell's core mission, they provide end-to-end services, from machine commissioning to adapting to new materials, enabling customers to quickly respond to changing demands in a dynamic market and maximize resource utilization.

Q5: What challenges does Back Twist technology face when processing new materials? How does Gemwell provide support to overcome these obstacles?

A5: The challenge of processing new materials (such as high-strength alloys or environmentally friendly polymers) lies mainly in the adverse effects of material properties on the torsion process: for example, changes in hardness may lead to uneven torsion, increasing the risk of breakage; or heat-sensitive materials may cause torque fluctuations, affecting signal stability. Back Twist technology requires adaptive adjustment of the torsion curve to maintain uniformity. Gemwell's support in this area reflects its innovation orientation - the company provides engineering consulting services to help customers develop customized torsion solutions, such as predicting material behavior through simulation software and integrating sensor systems for real-time correction. This strengthens Gemwell's commitment to partners: when developing new products, they not only provide technical resources, but also share global experience to ensure that the processing of new materials does not affect the core performance of the cable, ultimately driving the industry's transformation to green and efficient.