Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

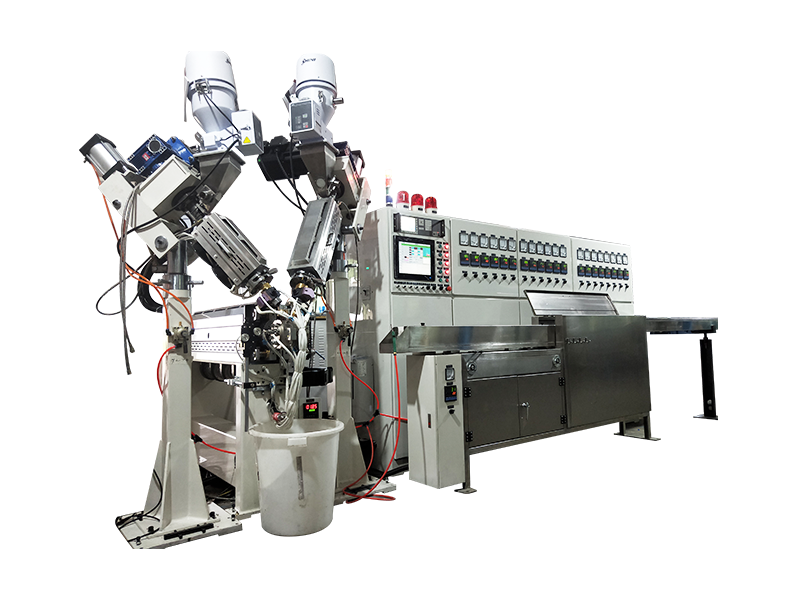

Q1: Why is the backtwist twisted-pair process essential for automotive data cables? What is the physical principle behind this?

A: In high-frequency signal transmission, the pitch accuracy and pair symmetry of twisted-pair cables directly determine impedance stability. Traditional twisting processes cause wire pair deformation due to residual stress in the conductors, leading to signal crosstalk and delay skew. Backtwist technology actively releases internal torsional stress in the conductors, maintaining a "zero torque" state at the twist points. This ensures:

No distortion in the conductor insulation geometry

Pitch error controlled within ±0.1mm

Phase delay difference ≤5ps/m. Based on 20 years of automotive cable process database, Gemwell Electric Technology's backtwist mechanism utilizes a dynamic inertia compensation algorithm, adapting to zero-tension fluctuation production of conductors from 0.08mm² to 2.5mm² at line speeds of 800m/min.

Q2: How is micron-level conductor synchronization achieved during high-speed twisting?

A: The core lies in the coordinated efforts of three key elements:

Active backtwist unit: Gemwell utilizes a dual-servo closed-loop system. Real-time encoder feedback is used to monitor spindle rotation and backtwist angular displacement, achieving an angular tracking accuracy of ≤0.05°.

Low-inertia guide pulley assembly: A ceramic guide pulley assembly with air bearings reduces the moment of inertia to 1/8 that of traditional steel pulleys, preventing the transmission of micro-vibrations.

Tension waveguide technology: Using a laser diameter gauge and hysteresis brake for millisecond-level response, conductor tension fluctuations are controlled to ±2cN (the Category 6a standard is ±15cN). This technology has been deployed in over 10,000 units delivered by Gemwell, maintaining a 99.3% UTP yield even with 48AWG conductor stranding.

Q3: What special environmental tolerances does the back twist pair twisting machine for automotive data cable need to meet?

A: Unlike ordinary communication cables, automotive cables must pass the following tests:

Thermomechanical fatigue testing: Maintaining pitch stability during cycling at -40°C to 150°C (ISO 6722 standard);

Chemical corrosion resistance: Maintaining insulation adhesion even under penetration of transmission oil, brake fluid, and other substances;

Vibration spectrum compatibility: Signal integrity under random vibration conditions from 20Hz to 2000Hz. Gemwell's solution includes: titanium alloy coating on the twisting heads (acid and alkali corrosion resistance), a temperature-compensated lay controller (±0.5% temperature differential compensation), and a library of over 200 automotive cable-specific process formulas developed in collaboration with Tier 1 suppliers.

Q4: How do you address the challenges of multi-layer composite twisting for autonomous driving domain control cables?

A: For FAKRA/Ethernet composite cables (such as 2Pair+4Dataline) for ADAS systems:

Hierarchical Phase Management: A differential lay length algorithm (Gemwell's patented TW-ART® 3.0) is used to maintain the pitch of different pairs in a golden ratio, suppressing inter-layer crosstalk.

Dielectric Isolation Technology: An in-line integrated foam barrier layer maintains a stable dielectric constant of 1.8±0.05 (100MHz).

Real-time ODD Monitoring: A machine vision system detects concentricity deviations >5μm and automatically corrects them. Based on practical data from over 300 cable manufacturers worldwide, Gemwell's composite twisting solution reduces high-frequency attenuation to ≤3.2dB/100m at 600MHz.

Q5: How does Gemwell's engineering collaboration model improve the overall efficiency of equipment?

A: Unlike standard equipment delivery, Gemwell implements:

Process-Equipment Twin Development: IoT sensors are deployed in customer factories to collect over 100,000 sets of vibration, temperature, and tension data to train equipment control models.

Predictive Maintenance Engine: By analyzing the harmonic characteristics of spindle bearings, failure risks are predicted 300 hours in advance.

Dynamic Efficiency Optimization: Back-twist gain parameters are automatically adjusted based on raw material batch differences, reducing changeover time by 37%. A typical case study: A US automaker's 48Gbps transmission line project reduced the transmission bit error rate from 10⁻¹² to 10⁻¹⁵ through Gemwell's customized twisting solution, improving the production line's OEE to 92.1%.

Q6: What new requirements does the next generation of automotive Ethernet cables place on twisting equipment?

A: To meet 28Gbps+ transmission rates (IEEE 802.3ch):

Nano-level surface treatment: The guide pulley surface roughness must reach Ra ≤ 0.05μm (mirror-grade).

UHF impedance control: Impedance tolerance of ±1Ω at 40GHz requires a lay-length dynamic compensation response of <5ms.

AI-driven process optimization: Utilizing deep learning to predict stress relaxation curves for different insulating materials (such as PFA/FEP). Gemwell is currently verifying a quantum annealing algorithm that can reduce the computational time for multi-objective optimization (pitch/tension/speed) from hours to seconds, paving the way for the mass production of automotive Terabit Ethernet cables.