Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

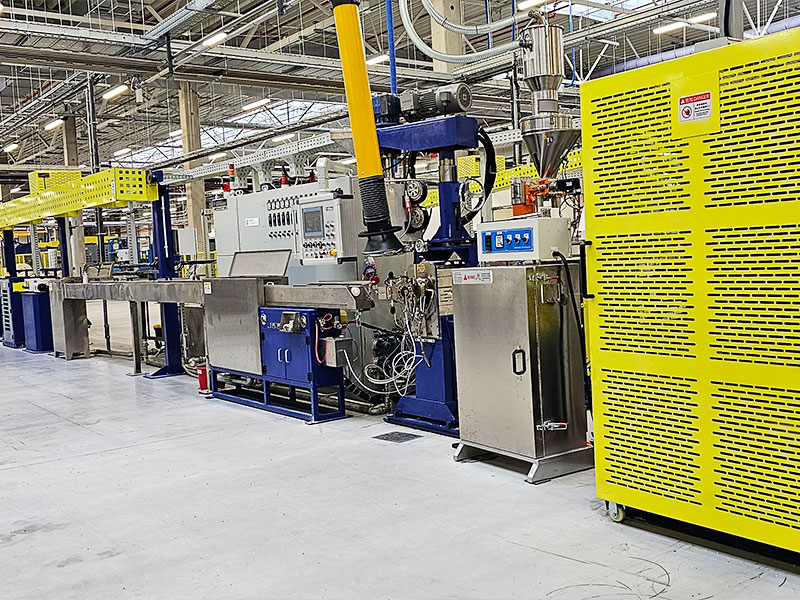

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

2026-01-12

2026-01-12

Webmaster

Webmaster

Replacing the cables on a wire and cable extruder is a maintenance task that requires care and patience. Here, "cables" typically refers to the power

Read More +

2026-01-05

2026-01-05

Webmaster

Webmaster

In the wire and cable industry, there are numerous manufacturers of wire and cable extruders. Based on the size of the manufacturers, their technologi

Read More +

2025-12-29

2025-12-29

Webmaster

Webmaster

Although an extruder machine looks like a bulky, heavy metal cabinet, its internal structure is very sophisticated. We can imagine it as a "superheate

Read More +

2025-12-22

2025-12-22

Webmaster

Webmaster

The working process of an extrusion machine is similar to squeezing toothpaste or using a piping bag to decorate a cake. It uses pressure to force sof

Read More +

In the wire and cable manufacturing industry, wire and cable machinery is core equipment. Its technological depth and breadth of application directly determine product quality and market competitiveness. As a company focused on technological innovation, consistent quality, precision manufacturing, and attentive service, how does Gemwell Electrical Technology (Jiangsu) Co., Ltd. incorporate its philosophy into equipment development?

What are the core functions of wire and cable machinery? What key role does it play in wire and cable production?

Wire and cable machinery broadly refers to specialized equipment used in wire and cable manufacturing, including extruders, stranding machines, testers, and sheathing equipment. The core function of this equipment is to transform raw materials (such as copper conductors and insulation) into finished cables, ensuring electrical performance, mechanical strength, and durability. During production, they precisely control parameters such as temperature, speed, and tension, achieving continuous, automated operation and improving efficiency and consistency. For example, within the industry, companies like Gemwell Electrical Technology have optimized equipment design through technological innovation, ensuring stable extruder output under high temperatures and pressures, thereby reducing scrap rates. This not only reflects a commitment to consistent quality but also reduces human error through precision manufacturing, ultimately delivering high quality to customers. After all, the depth of equipment functionality is directly linked to product reliability, which is the foundation of a company's value.

How does technological innovation drive industry progress in wire and cable machinery? What specific impact does it have on equipment performance?

Technological innovation is the driving force behind the development of wire and cable machinery, primarily in the areas of intelligent control, energy-saving design, and material compatibility. By incorporating PLC (Programmable Logic Controller) and IoT (Internet of Things) technology, equipment can monitor production parameters in real time and automatically adjust extrusion rate and stranding tension to avoid cable defects such as bubbles or deformation. This not only increases production capacity but also reduces energy consumption. For example, the new extruder utilizes variable frequency drive technology, achieving energy savings of up to 20%. As the industry progresses, this innovation ensures that equipment can adapt to diverse needs, such as the production of high-voltage cables or specialty cables. Companies like Gemwell Electrical Technology, through continuous research and development, integrate innovation into the core of their equipment, emphasizing the optimization of every detail—for example, precision manufacturing ensures component tolerances are controlled to the micron level—to provide customers with efficient solutions. Customer success often stems from this, as stable and advanced equipment directly enhances their market competitiveness, which is a reflection of corporate value.

Why is stable quality so crucial in wire and cable machinery? How do equipment manufacturers ensure product reliability through quality control?

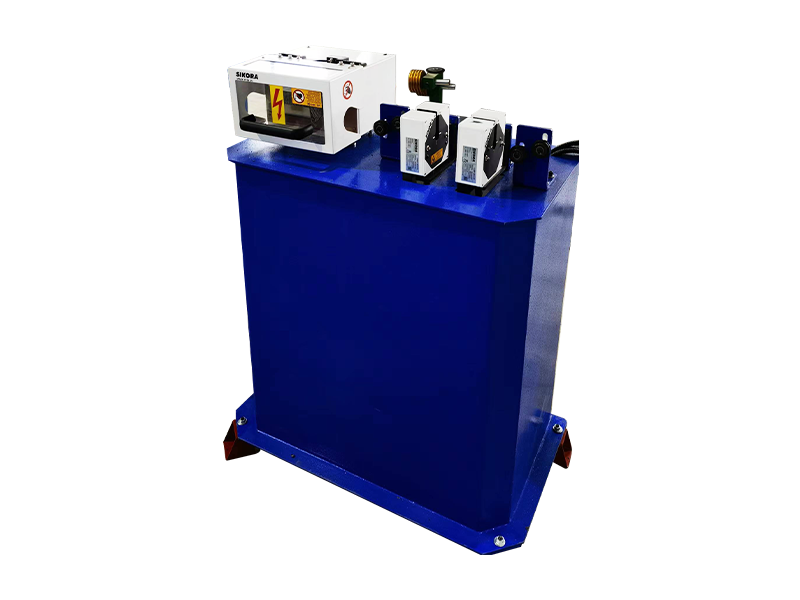

Stable quality is the lifeblood of wire and cable equipment, as it directly impacts the safety and lifespan of finished cables. Equipment must ensure consistent parameters, such as uniform insulation thickness or stable conductor resistance; otherwise, cable overheating, short circuits, or failure can occur. Quality control measures include online inspection systems (such as X-ray or laser thickness gauges) and regular calibration to identify and correct deviations. For example, in sheathing equipment, temperature fluctuations exceeding ±1°C can cause material degradation, so manufacturers maintain stability through redundant control and feedback mechanisms. Gemwell Electrical Technology emphasizes precision manufacturing, focusing on every detail—from material selection to assembly accuracy—to ensure trouble-free equipment operation over the long term. This not only meets customer demand for reliability but also provides attentive service and preventive maintenance, prioritizing customer success as a core component of corporate value.

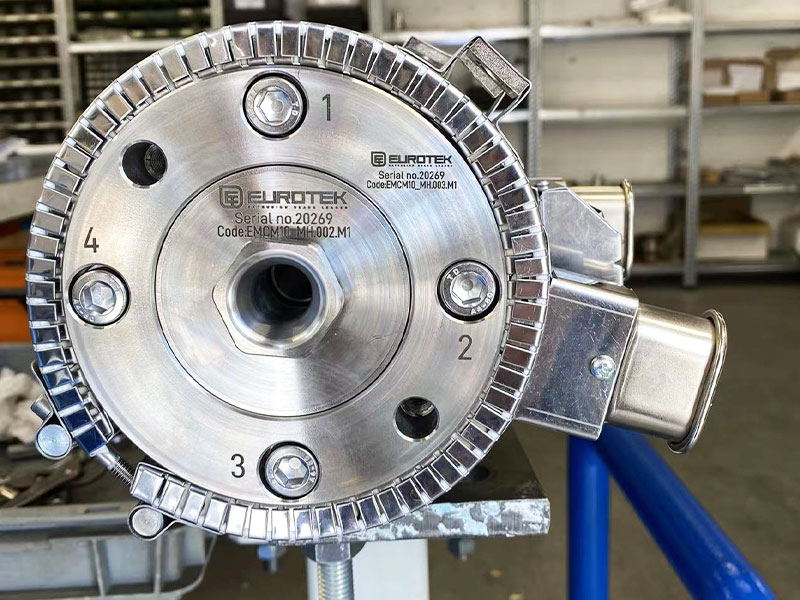

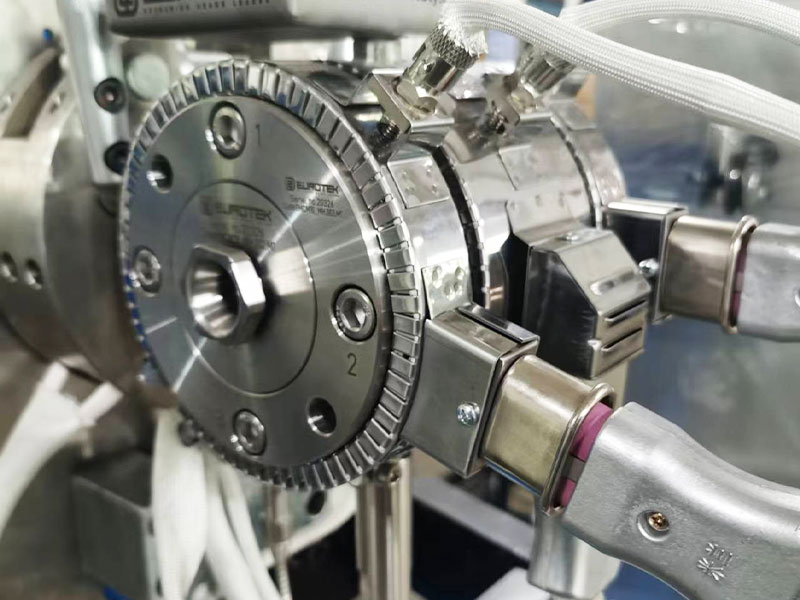

What role does precision manufacturing play in the design and production of wire and cable machinery? How does it enhance the overall performance of the equipment?

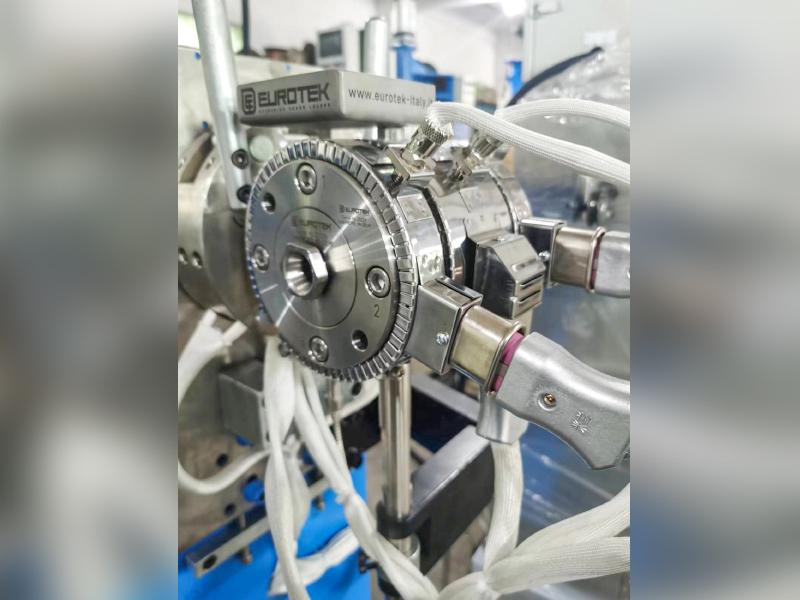

Precision manufacturing emphasizes high-precision machining and strict process control, and is the cornerstone of high-performance equipment. Within the design, this involves the precision manufacturing of key components, such as the wear-resistant coating on the extrusion screw or the gear drive system of the stranding machine, to ensure smooth movement and minimize wear. This improves the durability and efficiency of the equipment. For example, through CNC (computer numerical control) machining, component tolerances can be controlled to within 0.01mm, reducing vibration and noise, thereby extending the equipment life. This overall performance improvement is reflected in production consistency—precision manufacturing prevents the accumulation of minor defects, such as uneven wire diameter, which can degrade cable performance. Companies like Gemwell Electrical Technology adhere to this philosophy, paying attention to every detail, from raw material inspection to final testing, to ensure high-quality output. This focus not only strengthens quality consistency but also achieves cost optimization through technological innovation, ultimately prioritizing customer success as the company's core value.

How is attentive service reflected in Wire and Cable Machinery's customer relationships? What is its significance for long-term partnerships? Thorough service, encompassing pre-sales consultation, installation and commissioning, training, and maintenance support, is key to building trust between equipment manufacturers and customers. Within customer relationships, this manifests itself in rapid response to faults, customized solutions, and regular upgrade recommendations. For example, remote diagnostic systems can resolve equipment issues in real time, minimizing downtime. This is crucial for long-term relationships – timely service prevents production interruptions, improves customer operational efficiency, and fosters a strong partnership. Gemwell Electrical Technology values customer success as its core value and emphasizes attentive service, such as providing 24/7 technical support and operator training, to ensure equipment operates at its maximum potential. This not only reaps customer investment but also ensures seamless integration of service and equipment performance through precision manufacturing, translating technological innovation into tangible benefits.

Why is attention to detail essential in the manufacturing process of wire and cable machinery? How does it impact end-product quality?

Attention to detail is central to equipment reliability, as wire and cable production involves micron-level control. During the manufacturing process, details like the finish of the extrusion die or the fine-tuning of strand tension directly impact the cable's insulation uniformity and flexibility. Ignoring these details can lead to product defects, such as localized overheating or the risk of breakage. Therefore, equipment manufacturers implement strict process management to ensure precision at every step. Gemwell Electrical Technology adheres to meticulous attention to detail, from component assembly to system integration, emphasizing precision manufacturing. This not only ensures consistent quality but also optimizes detailed processes through technological innovation, such as using AI-assisted simulation to reduce human error. Ultimately, this delivers high quality to customers, ensuring cable products meet international standards and internalizing customer success as corporate value.

How does customer success tie into the corporate value of wire and cable machinery manufacturers? How does it drive industry innovation?

Customer success is core to the value proposition of equipment manufacturers because it reflects the actual effectiveness of equipment performance and service. When customers increase production or reduce scrap rates through efficient equipment, the manufacturer's corporate value is realized—incentivizing continuous innovation, such as developing environmentally friendly equipment or highly compatible systems. Within the industry, this connection drives manufacturers like Gemwell Electrical Technology to integrate technological innovation, consistent quality, and attentive service to ensure their equipment not only meets current needs but also anticipates future challenges. For example, precision manufacturing reduces maintenance requirements, allowing customers to focus on their core business, resulting in a win-win situation for both parties. Ultimately, the value of the company lies in helping customers stand out in a highly competitive market, which is the result of attention to detail and precision manufacturing.