Product Category

Product Category

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

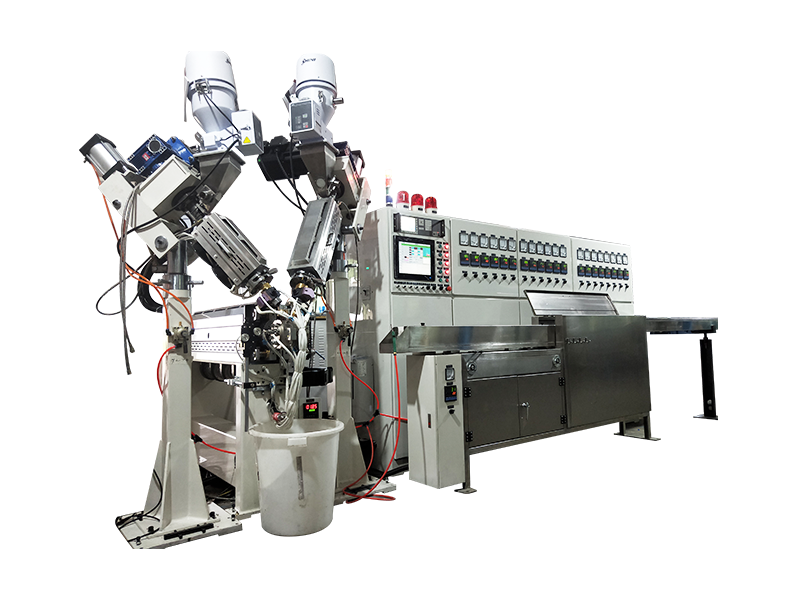

In today's rapidly developing network infrastructure, triple pitch pair twisting machines (TPPs) are core equipment in network cable manufacturing, and their performance directly impacts the quality and efficiency of data transmission. Gemwell Electrical Technology (Jiangsu) Co., Ltd. (hereinafter referred to as "Gemwell Electrical Technology") leverages its extensive experience in the electrical field to provide customers with targeted maintenance and optimization services, helping companies maximize equipment availability.

1. Question: What is a triple pitch pair twisting machine, and why is it indispensable in network cable production?

Answer: A triple pitch pair twisting machine is a type of equipment specifically designed for network cable manufacturing. Its core function is to precisely twist three pairs of independent wires at a specific pitch, creating a standardized cable structure. This twisting process effectively reduces electromagnetic interference (EMI) and signal crosstalk by controlling pitch variation (the difference in spacing between wire pairs), thereby ensuring the integrity and stability of data transmission. It is indispensable in network cable production because high-speed Ethernet (such as Cat6 or Cat7) cables require strict impedance matching and signal shielding. The triple pitch design optimizes the cable's electrical performance and minimizes bit error rates during data transmission. Gemwell Electrical Technology, through its professional team, can quickly assess the operating status of such machines, helping companies identify potential defects, ensuring production lines consistently meet industry standards, and avoiding communication quality issues caused by equipment failure.

2. Question: What are the key technical elements involved in the operating principle of a triple pitch pair twisting machine for network cable?

Answer: The machine's operating principle is based on precise mechanical control and materials engineering. Key elements include the pitch adjustment mechanism, tension control system, and twisting head design. The pitch adjustment mechanism allows the operator to dynamically adjust parameters based on cable specifications (such as twist length and angle), ensuring even distribution of twisting force across each pair of wires. The tension control system maintains stable wire tension during the twisting process, preventing cable deformation or breakage due to over-tightening or under-tightening. The twisting head design utilizes high-precision bearings and wear-resistant materials to achieve smooth rotation and reduce friction losses. These factors work together to ensure consistent electrical properties and physical durability in twisted cables. Gemwell Electrical Technology's experts thoroughly examine the wear of these components during service, for example, predicting bearing life through vibration analysis. They then provide targeted optimization recommendations to help companies extend equipment life and reduce maintenance costs.

3. Question: Why is triple pitch twisting critical to the signal quality of network cables?

Answer: Signal quality in network cables is directly dependent on twisting accuracy, as irregular pitches can lead to impedance imbalance, which in turn causes signal attenuation and crosstalk. triple pitch design, through differentiated pitches (for example, using different pitch lengths for each pair of wires), creates a "self-shielding" effect, effectively counteracting external electromagnetic interference. This is particularly critical at high-speed data transmission (e.g., above 10 Gbps), where even slight deviations can cause packet loss or delay. Furthermore, the twisting process must consider material properties, such as the purity of the copper conductor and the dielectric properties of the insulation, to ensure low signal transmission loss. Gemwell Electrical Technology's service team assesses the coordination of the entire stranding system, for example, using thermal imaging to detect local hot spots. They then provide reports to guide companies in optimizing process parameters, thereby improving cable transmission efficiency and reliability from the very beginning.

4. Question: How can unexpected failures of triple pitch twisting machine for network cables be prevented and their efficiency maintained during production line operation?

Answer: Preventive maintenance is a core strategy, involving regular calibration, component inspection, and environmental monitoring. Calibration ensures accurate pitch setting and tension control, preventing parameter drift from affecting stranding quality. Component inspection focuses on vulnerable parts such as the twisting head and drive system to detect signs of wear early. Environmental monitoring includes temperature and humidity control to reduce corrosion or static interference. Gemwell Electrical Technology's professional services play a key role in this: depending on the production line type (e.g., high-frequency or high-volume production), their technicians will thoroughly inspect every component, from the mechanical drive to the electrical control unit, within 1-3 days. The subsequent written report not only details the current status (e.g., gear backlash or motor efficiency) but also provides improvement recommendations, such as upgrading the lubrication system or adjusting maintenance intervals. This report serves as a valuable guide for maintenance teams, helping them plan preventative measures, significantly reduce unplanned downtime, and ensure continuous equipment operation at high efficiency.

5. Question: How does Gemwell Electrical Technology help companies optimize the overall availability of triple pitch twisting machine for network cables through its services?

Answer: Gemwell Electrical Technology's core strength lies in its customized maintenance solutions and expert insights. They focus not only on the machine itself but also analyze availability issues from a holistic production line perspective, for example, assessing the compatibility of the twisting process with other processes such as shielding or jacketing. The experienced team identifies potential bottlenecks, such as the compatibility of pitch settings with production speed, and provides data-driven optimization recommendations. For example, the report might emphasize regular analysis of machine data to predict failure probabilities and recommend preventative component replacement plans. This not only minimizes downtime risks (statistically, professional maintenance can reduce unplanned interruptions by up to 30%) but also improves capacity utilization. Through this collaborative approach, companies can transform the operational stability of their triple pitch twisting machine for network cables into a competitive advantage, such as faster delivery of high-quality cables, thus gaining a competitive advantage in a competitive market.

6. Question: What are the long-term benefits of choosing Gemwell Electric Technology's services for your company?

Answer: In the long term, this partnership offers multiple benefits: First, through preventative maintenance planning, the company can significantly reduce its total cost of ownership (TCO), avoiding costly downtime and emergency repairs. Second, Gemwell Electric Technology's reports provide actionable insights to help the maintenance team improve their skills, such as through recommended training modules to enhance their understanding of triple pitch technology. Finally, the service ensures that equipment is always operating at peak performance, supporting the company's adaptation to changing network standards (such as upgrading to Category 8 cable). Gemwell Electric Technology's professional approach not only optimizes the availability of its triple pitch twisting machine for network cables but also enhances production continuity by reducing unplanned downtime, allowing the company to focus on core innovation and market expansion. Ultimately, this partnership translates into sustainable productivity gains and competitive advantage.