Product Category

Product Category

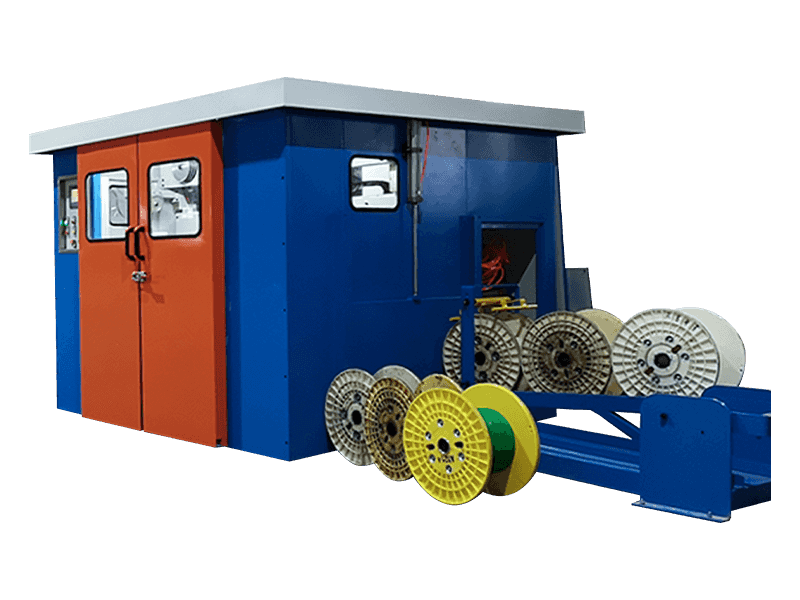

During taping process, the core wire and tape pay off separately. Then, tape material is wrapped around the core wire with stable tension to form a wire. For the ordinary taping machine, magnetic powder clutches are selected as tension elements. As the rotor of the clutch and the magnetic powder are of contact structure mechanism, the frictional heat energy generated during high-speed rotation causes the tension output of the magnetic powder clutch to be unstable. In addition, after the magnetic powder is used for a period of time, the magnetic force will decrease or even disapear, resulting in a smaller torque generated on the taping head and further influencing machine’s normal production. The magnetic powder needs to be replaced regularly, and it makes maintenance troublesome and costly. In order to solve such problems, this machine uses a hysteresis clutch as the tension element to replace the original magnetic powder clutch. The hysteresis clutch consists of a hysteresis stator and rotor. When the coil of the hysteresis stator is charged, an electromagnetic field is generated in the annular space of the hysteresis stator. When the hysteresis rotor rotates, it cuts the electromagnetic field to generate resistance (torque). This torque acts on the strip material as the tape tension. Since the hysteresis rotor does not have a mechanical contact with the hysteresis stator when rotating, no mechanical friction heat energy is generated, thereby achieving stable tape tension output. By adjusting the hysteresis stator current, different torques can be outputted, thereby achieving tension adjustment with simple, compact and durable structure.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

In the field of electrical equipment manufacturing, hysteresis tension type wire taping machines represent the cutting edge of winding precision. Gemwell Electrical Technology (Jiangsu) Co., Ltd., leveraging its deep integration of electromagnetic technology and precision mechanics, has developed this equipment as a core process enabler.

I. What is the core principle of hysteresis tension control? Why is it the cornerstone of precision winding?

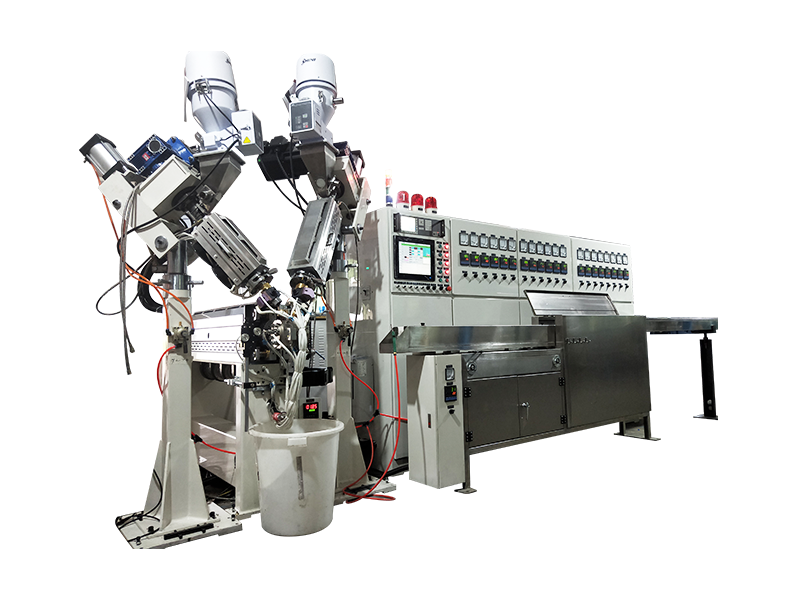

This tension control system is based on the unique physical properties of hysteresis materials. When a wire passes through a specially designed hysteresis brake, the system doesn't rely on simple friction or mechanical pressure, but instead utilizes the inherent energy loss characteristics (hysteresis loss) of hysteresis materials in an alternating magnetic field to generate a stable, slip-free braking torque. Gemwell Electrical Technology, with a deep understanding of this principle, uses precise material selection and magnetic field structure design to ensure that tension output is unaffected by wire speed fluctuations. This fundamentally eliminates the "slippage" or "overtightening" issues common with traditional mechanical brakes, laying the physical foundation for lossless winding of sensitive materials such as enameled wire and ultra-fine wire.

II. Why is constant tension so crucial to the performance of electrical components? How does Gemwell achieve this?

The electrical consistency (e.g., inductance and Q factor) and mechanical stability (resistance to vibration and thermal expansion and contraction) of winding coils are critically dependent on constant wire tension. Tension fluctuations can lead to: uneven tension between coil layers, causing abnormal distributed capacitance; microscopic deformation accumulation, reducing long-term reliability; loose windings or excessive embedding, which can affect heat dissipation and even cause inter-turn shorts. Gemwell's solution is a closed-loop tension control system: a real-time, high-precision sensor monitors actual tension, compares it to the preset value, and then dynamically adjusts it within milliseconds using a high-speed hysteresis brake/drive unit. This "sense-feedback-actuate" closed-loop logic ensures micron-level tension stability from the start to the end of winding, providing significant advantages under high-speed or rapid start-stop conditions.

III. How do precision wire routing and tension control work together? What is Gemwell's unique feature?

The ultimate goal of a winding machine is to achieve tight, uniform, and gap-free wire routing. This requires that the precise displacement of the wire-traversing mechanism (with guide wheels or leadscrews typically achieving micron-level accuracy) be perfectly synchronized with the spool's rotation and tension control. Gemwell engineers deeply integrated the tension control unit with a high-resolution servo wire-traversing system, developing a unique collaborative algorithm. This system dynamically compensates for wire-traversing pitch errors caused by subtle variations in wire diameter and increased spool diameter (the "taper effect"), while also counteracting inertial tension disturbances caused by acceleration changes. This enables stringent process requirements such as the ultra-tight spacing required for high-frequency transformer coils or multi-layer precision random winding.

IV. How to overcome the challenges of high-speed operation? What are Gemwell's technological breakthroughs in dynamic response?

While increasing wire speed improves efficiency, it also exacerbates the difficulty of tension control—factors such as inertia, vibration, and air resistance intensify their impact. Traditional mechanical or pneumatic tensioners exhibit significant response lag. Gemwell's hysteresis tension system, thanks to its non-contact operating principle and the inherently rapid electromagnetic response, offers excellent dynamic performance. The key lies in its core hysteresis drive module, which adjusts the excitation current within milliseconds, instantly changing the output torque and rapidly suppressing high-speed wire "jitter" or "surge." This ensures that tension ripple remains strictly within process tolerances even at winding speeds of several kilometers per minute.

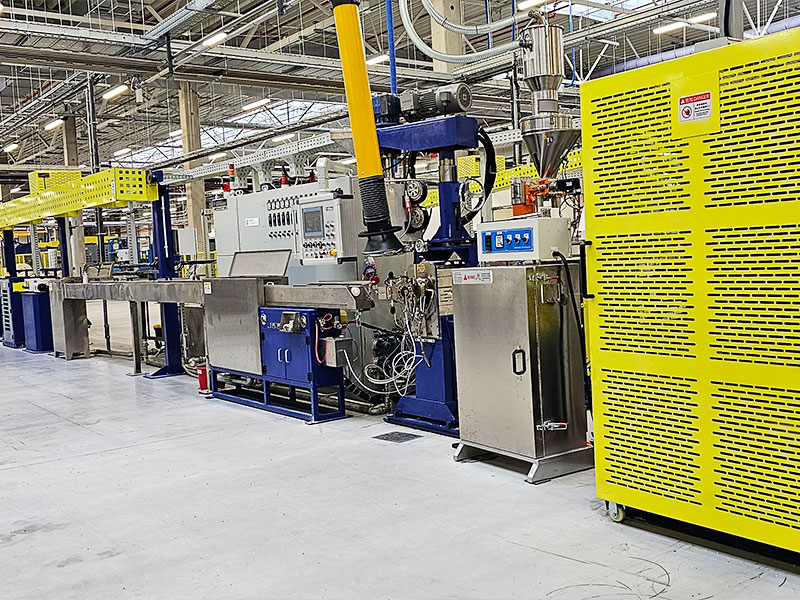

V. How does intelligent operation and maintenance enhance equipment value? What is the practical significance of Gemwell remote diagnostics?

Modern high-end winding machines are no longer isolated machines but deeply integrated mechatronic systems. The remote diagnostic technology embedded in the Gemwell platform serves as the "nerve center" for equipment health management. An embedded sensor network continuously collects key parameters such as tension fluctuation spectrum, motor current harmonics, and bearing vibration, and combines them with big data models for status analysis and fault warning. If the system detects abnormal deviations in the tension feedback curve or a trend of declining brake unit efficiency, Gemwell engineers can remotely access the system to retrieve operation logs, perform software parameter calibration, and even provide on-site maintenance guidance, avoiding unplanned downtime. This capability is particularly valuable in the context of a globalized supply chain (such as during logistics disruptions during the pandemic), enabling customers to receive near-zero-wait technical support and maximizing production continuity.

The hysteresis tension type winding machine is not only a tool for forming wires but also a technological culmination of electromagnetics, material mechanics, and precision control engineering. By continuously exploring the application boundaries of hysteresis materials, optimizing closed-loop control algorithms, and integrating intelligent operations and maintenance systems, Gemwell Electrical Technology (Jiangsu) Co., Ltd. is unleashing the full potential of this precision equipment, making it a key enabler for ensuring the consistent performance and reliability of high-end electromagnetic components. Its technological evolution continues to set new standards for winding process precision.