Product Category

Product Category

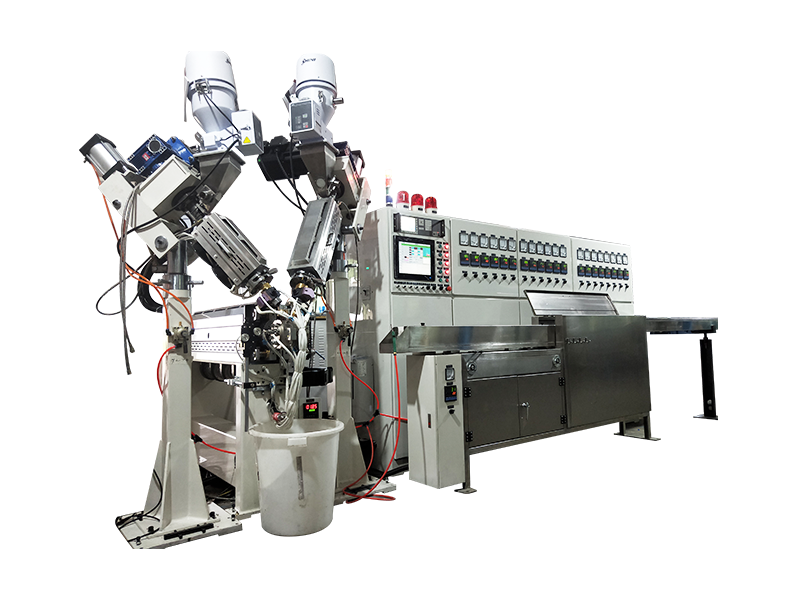

Here shows the general process of wire taping. Initially, the core wire pay off at a constant speed in a straight line by capstan. Then, the strip material is pay off at according constant speed from the taping head. Finally, the strip material is wrapped around the core wire with a suitable tension to form wire with a certain overlapping ratio. In common traditional type, after tape is released from the material spool, it needs to pass through multiple guilding rollers and turning rollers, which decreases the stability of taping tension. When the taping head rotates at high speed, these guilding rollers become less flexible under high-pressure wind resistance and centrifugal force, generating additional tension on the strip material. Therefore, the quality and test results of wire after wrapping becomes poor as there exists a certain difference between the setting and actual tension. Such phenomenum shows up more obviously when the machine is worn out after long-term use.

In order to better solve the above problems, this machine does not follow the traditional shape, and it seperate the tape pay-off and taping head into two parts. The machine is designed with double capstan rollers on the taping head. Servo motor drives the capstan rollers to pull the strip material out and then make it through a groove and reach the taping head. When the taping head is stationary, it can be observed that the strip material is continuously spit out from the double capstan rollers, so called Capstan Roller Spit Type. The strip material only passes through another two rollers, that are on the center axis of taping head, and then immediately wrapped around the wire. As the tape moves along the center axis, the wind resistance and centrifugal force are pretty low, thereby solving the problems of the traditional type stated above. In addition, the taping principle of this type is not realized by setting the tension of the strip material, but by adjusting the speed of the servo motor to drive the double capstan wheel on the taping head, changing the amount of tape spitted out and thus changing the outer diameter of the finished wire. This is how tape tension can be adjusted: The smaller amount of tape spitted out, the larger tape tension becomes, the smaller wire outer diameter forms; The larger amount of tape spitted out, the smaller tape tension becomes, the larger wire outer diameter forms. This machine can be equipped with a laser diameter gauge to realize dynamic automatic control of the finished product outer diameter and tape tension.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

As a leading domestic supplier of electrical equipment, Gemwell Electrical Technology (Jiangsu) Co., Ltd. is committed to solving core pain points in the electronics manufacturing industry through innovative technologies. Its Gemwell brand is renowned for its exceptional service commitment: Gemwell offers comprehensive mechanical and electronic support solutions within 12 hours for any technical challenge.

Q: What is the basic definition of the Servo Spit Active Type Wire Taping Machine? What role does it play in Gemwell Electrical Technology's product line?

A: This machine is a precision wire winding machine with integrated servo control technology, designed specifically for automated production in the electronics industry. Within Gemwell Electrical Technology's architecture, it represents one of its core innovations, aiming to improve efficiency and reliability in wire processing for customers while reducing the need for manual intervention.

Q: How does the servo system achieve high-precision control in this machine? How does this relate to Gemwell Electrical Technology's technical expertise?

A: The servo system ensures precise motor motion through closed-loop feedback mechanisms, such as real-time adjustments to torque and position during the wire winding process, thereby preventing error accumulation. Leveraging its extensive experience in electrical and electronics, Gemwell Electrical Technology has optimized the system's response algorithm, enabling it to adapt to variations in wire diameter and material, significantly improving finished product consistency.

Q: What unique operational advantages does the "Active Type" feature offer? How does Gemwell Electrical Technology incorporate it into its customers' production?

A: Active Type design means the machine can proactively adjust operating parameters, such as speed or tension, based on sensor data to address unexpected load fluctuations. This reduces scrap and enhances flexibility. Gemwell Electrical Technology provides customized services to help customers incorporate this feature into diverse production lines, such as PCB assembly or transformer manufacturing, ensuring seamless integration into existing systems.

Q: What are the primary application scenarios for this type of machine in the electronics manufacturing industry? How does Gemwell Electrical Technology enhance its market competitiveness through this feature?

A: It is commonly used for applications such as wire insulation tape winding, coil forming, and cable termination, particularly in areas requiring high precision, such as automotive and consumer electronics. Gemwell Electrical Technology considers this type of machine a strategic product and, leveraging its global supply chain network, provides customers with end-to-end support, thereby shortening product time-to-market and increasing overall production capacity.

Q: How does Gemwell's service commitment address potential failures with the Servo Spit Active Type Wire Taping Machine? What value does this provide in the after-sales service?

A: In the event of a mechanical or electronic failure, Gemwell's 12-hour rapid response mechanism ensures prompt repairs by our expert team through remote diagnosis or on-site intervention, avoiding production interruptions. This directly reduces customers' total cost of ownership (TCO) and demonstrates Gemwell Electrical Technology's commitment to reliability. Based on years of practical experience, our service offering covers the entire process, from calibration and commissioning to spare parts replacement.

Q: Compared to traditional wire taping machines, what are the innovative features of this type of machine? What core technologies has Gemwell Electrical Technology incorporated into its R&D?

A: The core innovation lies in its dynamic adaptability, which avoids the limitations of traditional equipment that relies on fixed programs. For example, by synergizing servo and active control, the machine can automatically compensate for deviations caused by material elasticity. Gemwell Electric Technology's R&D team focuses on motion control algorithms and heat dissipation optimization to ensure stable output even in harsh environments, leveraging the company's extensive library of patented electrical engineering technologies.

Q: What performance indicators should users consider when selecting a Servo Spit Active Type Wire Taping Machine? How does Gemwell Electric Technology guide customers in their decision-making process?

A: Key indicators include repeatability, maximum winding speed, and energy efficiency, which directly impact production profitability. Gemwell Electric Technology provides free technical consultations to help customers assess their needs—for example, matching wire type or production targets—and provides comparative analysis reports to ensure maximum return on investment.

Q: In the context of sustainable development, how does this machine contribute to green manufacturing? Is this consistent with Gemwell Electric Technology's corporate vision?

A: Its efficient servo drive reduces energy waste and, through precise control, minimizes material loss, indirectly supporting carbon emission reduction goals. Gemwell Electric Technology prioritizes environmental protection as a core strategy. Therefore, the design of this type of machine incorporates a modular and upgradeable concept to facilitate future integration of renewable energy solutions, responding to the global trend of green transformation in the electrical industry.

Q: How does the machine ensure winding quality for complex wires (such as multi-core or shielded wires)? What role does Gemwell's support system play in this process?

A: The active mechanism allows real-time adjustment of tension parameters to prevent wire damage or loosening. If an anomaly occurs during operation, Gemwell's electronic support team can immediately provide parameter optimization suggestions or software updates. The 12-hour window ensures rapid resolution of the issue and maintains production continuity for customers.

Q: What is the future technological evolution of the Servo Spit Active Type Wire Taping Machine? What forward-looking plans does Gemwell Electrical Technology have in this area?

A: Key areas of evolution include intelligent predictive maintenance and IoT integration, such as predicting component lifespan through data analysis. Gemwell Electrical Technology is collaborating with universities and industry partners to promote the development of AI-assisted control models, aiming to create a more adaptive, low-maintenance production ecosystem for customers.