Product Category

Product Category

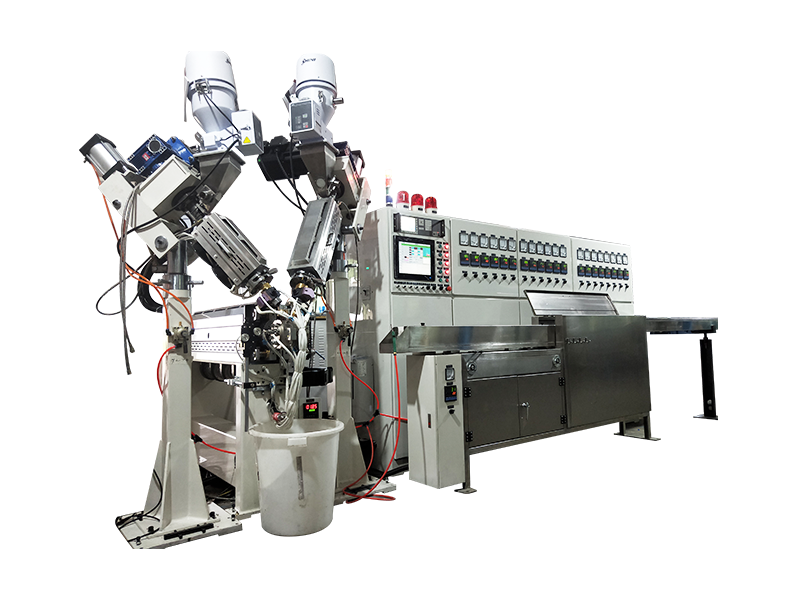

During taping production process, the core wire and tape pay off separately. Then, tape material is wrapped on the core wire with a suitable tension to form a wire. Tension remains constant with wire taping at a constant speed. However, as tape continues to be released from the material spool, the outer diameter of the spool becomes smaller, and the length of the tape released gets shorter each time when the taping head rotates. If the tape pay-off speed is not adjusted in time, it will affects the stability of the tape pay-off. In order to increase the stability, there is a need for a structure that can actively adjust pay-off speed and keep tape tension maintain constant. In order to achieve that, three servo motion controllers are used to control rotation and movement of taping head, material plate, and tension dancer respectively. The servo motion controller for tension dancer can not only maintain constant tape pay-off speed and tension, that drives the tension dancer adopts speed and torque modes, which not only provides constant speed and tension to the strip material, but also self-detects and auto-feedback its relative position to the rotating head. When the tension dancer runs over the preset zero position and moves along the same direction as taping frame rotation, it means that the speed of the servo motor of the tape pay-off is slow, which makes the encoder transmit a PID voltage signal to servo motion controllerter for accelerating the tape pay-off, and vice versa. Thus, realizing constant tension taping by active auto-feedback and stable tape pay-off process.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-16

2026-02-16

Webmaster

Webmaster

Direct Answer: What is Fish Tape and Its Primary Use? Fish tape is a stiff, flexible, and long tool used by electricians to pull wires through narrow

Read More +

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

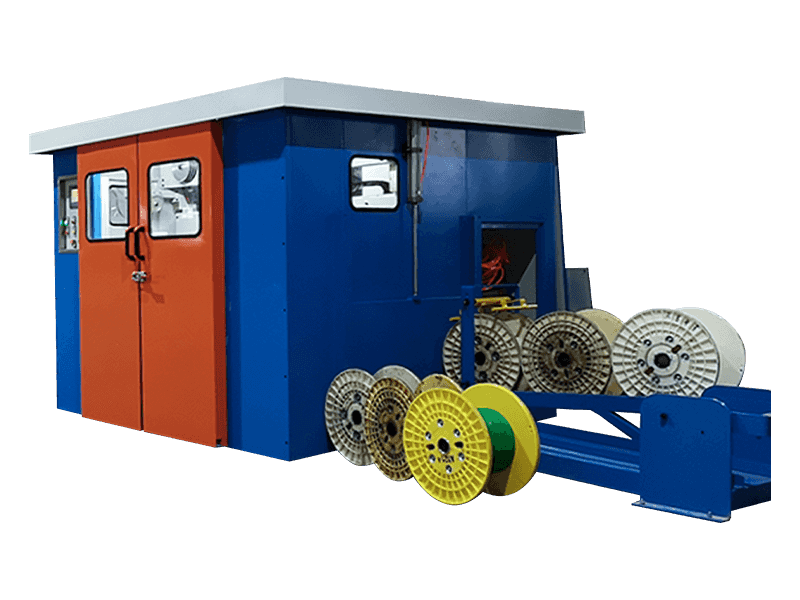

In modern automated manufacturing, the Three Servos Active Type Wire Taping Machine (3-Servo Active Type Wire Taping Machine) is a highly efficient device that is revolutionizing wire and cable processing. As a core member of the Gemwell Group, Gemwell Electrical Technology (Jiangsu) Co., Ltd. specializes in the installation, commissioning, and optimization of automated equipment, ensuring seamless integration of these machines into production lines.

Q1: What is the Three Servos Active Type Wire Taping Machine? What are its core components?

A: The Three Servos Active Type Wire Taping Machine is an automated device driven by three independent servo motors, designed for precision winding of wires and cables. Its core lies in its "active" control mechanism: the three servo motors are responsible for wire feeding, rotation, and tension adjustment, respectively, enabling real-time dynamic adjustment of the cable. This design eliminates the lag inherent in traditional mechanical transmissions, improving precision and flexibility. For example, in electronics manufacturing, it can handle automated winding of multiple cable sizes. Gemwell Electrical Technology (Jiangsu) Co., Ltd. provides professional installation services, helping customers build the physical framework of these machines and ensuring proper connection between the motors and control system to maximize their performance potential. The company emphasizes system coordination, eliminating potential conflicts through initial commissioning to ensure the machine performs optimally from the moment it is deployed.

Q2: How does this machine work? How do the servo motors achieve "active" control?

A: The machine's operating principle is based on a closed-loop feedback system using servo motors. Each motor independently responds to real-time data, forming a coordinated workflow. The wire feed motor controls the wire feed speed, the rotation motor drives the winding shaft for precise positioning, and the tension motor uses sensors to monitor wire tension and dynamically adjust to prevent breakage or slack. This "active" mechanism relies on high-precision encoders and controllers to achieve microsecond response, ensuring a smooth and error-free winding process. Gemwell Electrical Technology (Jiangsu) Co., Ltd. intervened during the commissioning phase, optimizing electrical connections and adjusting parameters, such as calibrating the servo drive's PID parameters, to ensure conflict-free coordination among the three motors. They also integrated with other production line components, such as the PLC or robots, to perform system-level optimization, avoiding efficiency losses caused by compatibility issues and ultimately achieving the stable operation expected by customers.

Q3: What are the core advantages of the Three Servos Active Type Wire Taping Machine? How does this machine improve efficiency compared to traditional equipment?

A: The machine's core advantages include high precision, high flexibility, and low energy consumption. Regarding precision, the servo motor provides positioning accuracy of ±0.1mm, making it suitable for processing fine wires. Its flexibility lies in its programmability, enabling rapid switching between different winding modes (such as spiral or parallel) via software without mechanical modification. Regarding energy consumption, active control activates the motor only when needed, reducing idling. Compared to traditional gear or belt-driven equipment, it can increase production efficiency by 20-30% while also reducing scrap. Gemwell Electrical Technology (Jiangsu) Co., Ltd. enhances these advantages through commissioning services, such as optimizing motion profiles during parameter adjustment to avoid overshoot or vibration. Furthermore, the company provides operator training to teach customers how to leverage the machine's flexibility to cope with fluctuating orders, ensuring continued energy-efficiency and efficiency over the long term.

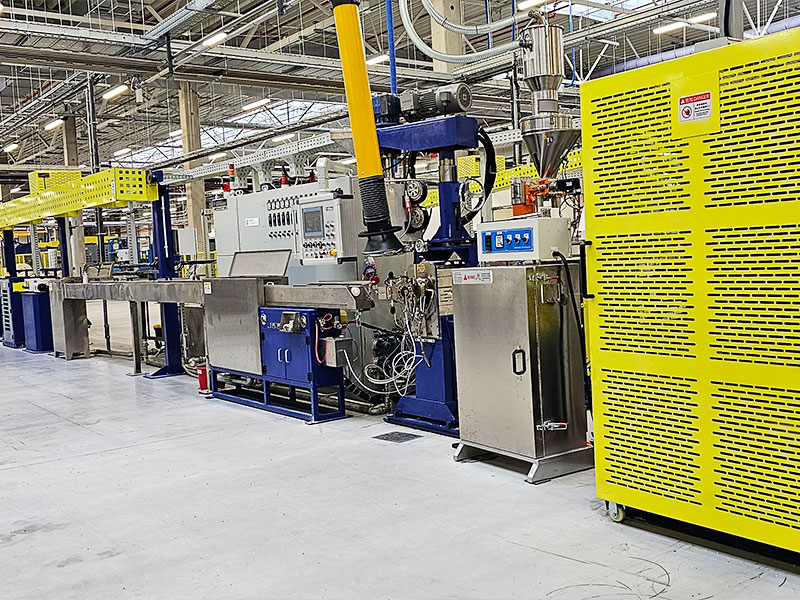

Q4: In what industries is this machine widely used? How does Gemwell Electrical Technology support its deployment?

A: The Three Servos Active Type Wire Taping Machine is widely used in electronics manufacturing, automotive wiring harnesses, and home appliance production, particularly for high-precision wire processing applications such as winding data or power cables. Its modular design allows for easy adaptation to diverse workpieces and meets small-batch customization needs. Gemwell Electric Technology (Jiangsu) Co., Ltd. plays a key role in the deployment: starting with the installation phase, they oversee the physical setup and wiring of the equipment, ensuring the servo system is compatible with the factory power grid. Subsequently, during commissioning, they program the control logic and conduct optimization tests simulating real-world production conditions. For example, in an automotive wiring harness factory, the company integrated the machine into a fully automated production line, eliminating bottlenecks through system commissioning. The service goal is always to ensure the machine's coordination with the overall production line, avoid the risk of downtime, and help customers maintain their advantage in a highly competitive market.

Q5: How does the training and technical support provided by Gemwell Electric Technology ensure the long-term operation of the machine?

A: Gemwell Electric Technology (Jiangsu) Co., Ltd. emphasizes knowledge transfer, providing structured training to ensure customers can independently operate and maintain the machine. Training covers basic operation, troubleshooting, and preventative maintenance. For example, it teaches operators how to calibrate servo motors or replace sensors to prevent accuracy loss due to misoperation. Regarding technical support, the company provides real-time response mechanisms, offering remote or on-site guidance for unexpected issues (such as motor overheating or winding deviation) to minimize recovery time. This support stems from Gemwell's service philosophy: not only delivering equipment but also empowering customers to take ownership. Given the complexity of the Three Servos Active Type Wire Taping Machine, the company's training covers programming interfaces and parameter adjustment techniques, enabling customers to flexibly adapt to process changes and maintain efficient system operation for many years.

Q6: Why did you choose Gemwell Electric Technology for your Three Servos Active Type Wire Taping Machine? How does their service philosophy enhance overall value?

A: Gemwell Electric Technology (Jiangsu) Co., Ltd.'s services focus on system-level optimization and customization, rather than simply equipment installation. Their philosophy views automation as a holistic solution: through installation, commissioning, and integration, they ensure seamless coordination between the machine and the production line, maximizing the potential of proactive control. For example, during the programming phase, the company adjusts servo parameters to suit specific material properties and improve winding consistency. During the optimization phase, simulated load testing is used to prevent potential failures. This directly enhances the value of the Three Servos Active Type Wire Taping Machine, extending its service life and reducing total cost of ownership. Ultimately, the company aims for "harmonious operation" to help customers achieve a leap in production efficiency, embodying Gemwell Group's core mission of "technology-enabled manufacturing."