Product Category

Product Category

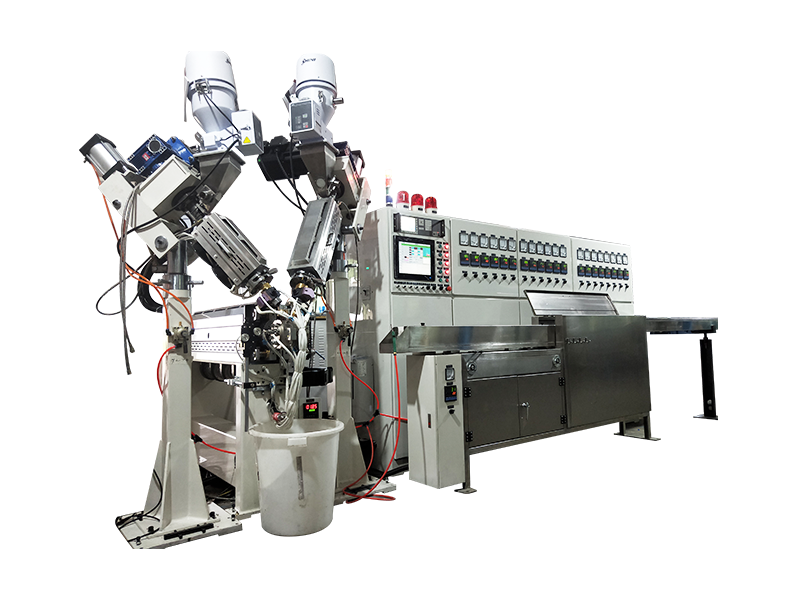

Twisting machine is a precision cable equipment that twists two independent core wires through high-speed rotation, precisely control the pitch and tension, and ultimately synchronously winding them into a single twisted wire unit. The twisting process not only enhances the flexibility and durability of the cable but also holds fundamental value in that, through its precise helical structure, the electromagnetic fields generated by the two conductors during signal transmission cancel each other out. This significantly suppresses signal crosstalk between the twisted pairs and improves the ability to resist external electromagnetic interference, laying the physical foundation for high-speed and stable signal transmission.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-09

2026-02-09

Webmaster

Webmaster

The Definitive Answer on Correct Electrical Tape Application To apply electrical tape correctly, you must stretch the tape as you wrap it and maintai

Read More +

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

2026-01-12

2026-01-12

Webmaster

Webmaster

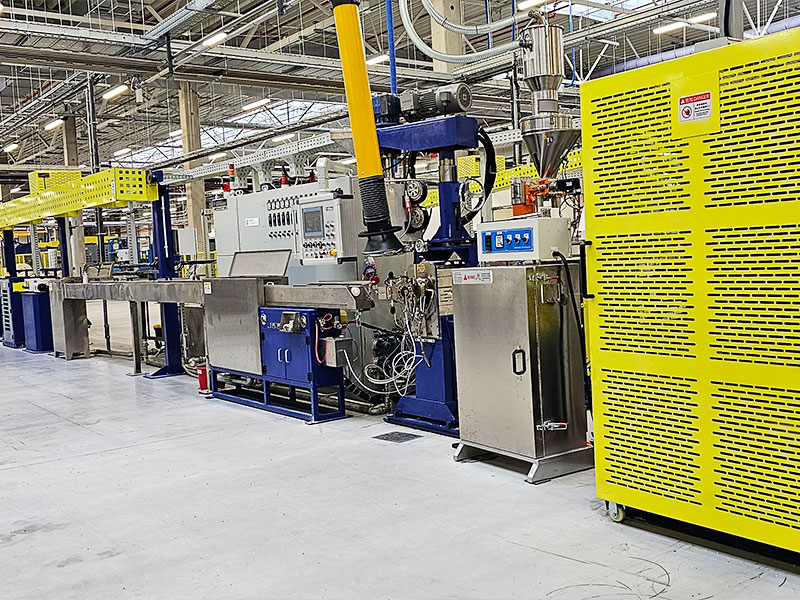

Replacing the cables on a wire and cable extruder is a maintenance task that requires care and patience. Here, "cables" typically refers to the power

Read More +

Q1: What is the core function of a wire pair twisting machine? How does its process affect the electrical performance of the cable?

A: This equipment achieves electromagnetic interference cancellation by precisely controlling the pitch and angle of the helical twist of two sets of conductors. The key lies in the twist pitch accuracy (unit: number of twists/meter) under constant tension, which directly affects the cable's impedance stability, crosstalk suppression, and signal transmission loss. Gemwell Electrical Technology utilizes a closed-loop servo control system in its design to ensure a dynamic lay pitch tolerance of ±0.2mm, improving the EMC performance of customers' cable products by over 30%—a move that aligns closely with Gemwell's vision of "creating value beyond expectations."

Q2: How do modern twisting machines achieve "double the result with half the effort" in production efficiency?

A: The core breakthrough lies in multi-axis collaborative technology:

Synchronized detwisting mechanism: Eliminates internal conductor stress and prevents pitch variation caused by springback (>95% detwisting efficiency).

Intelligent spool changing system: Supports fully automatic switching of 500kg spools, reducing downtime by 40%.

Energy efficiency optimization module: Regenerative braking technology recovers braking energy, saving 18% energy compared to traditional models. Gemwell's engineering team has integrated this technology into a modular platform, allowing customers to flexibly scale according to production capacity needs, truly achieving the "resource input-output ratio" optimization advocated by Gemwell.

Q3: What are the technical bottlenecks in micro-control of stranding precision?

A: Three core challenges and solutions:

Conductor micro-slip control: A ceramic guide wheel assembly and pneumatic pressure compensation clamping device are used to control the copper wire surface friction coefficient within the range of 0.08-0.12.

Dynamic vibration suppression: Gemwell's patented magnetic levitation active vibration damper reduces the amplitude to less than 5μm at 2000rpm.

Thermal expansion compensation: A temperature sensor and AI algorithm adjust the lay length in real time, achieving a temperature drift error of <0.01%/°C. These technical details reflect Gemwell's commitment to sustainable manufacturing—reducing material waste and energy consumption through precision engineering.

Q4: How do stranding machines adapt to the complex requirements of specialty cables?

A: The key lies in material compatibility and flexible production design:

Conductor adaptability: Supports lossless stranding of wires from 0.05mm ultra-fine enameled wire to 10mm² armored conductors.

Insulation protection: Anti-static guide rollers are used in low-tension areas to prevent scratching of the FEP/ETFE insulation.

Special twisting modes: One-touch switching between star and SZ twisting, with a programmable pitch range of 5-150mm. Gemwell's solutions have been applied in applications such as high-temperature aerospace wiring harnesses and high-voltage cables for new energy vehicles, fulfilling its corporate mission of "empowering industrial upgrading with technology."

Q5: How does intelligent equipment improve cable quality traceability?

A: Integrated Industry 4.0 architecture enables:

Digital twin system: Real-time mapping of each meter's twisting parameters (torque/tension/pitch) to the cloud.

Defect root cause analysis: AI compares over 100,000 process databases to automatically identify wire breakage and strand skipping.

Predictive maintenance: Vibration sensors monitor bearing status, with a fault warning accuracy rate of ≥92%. This enables Gemwell customers to achieve full lifecycle management capabilities and reduce product defect rates to below 50 parts per million (PPM).

Q6: How does the stranding process support sustainable development goals?

A: Gemwell's innovation focuses on three dimensions:

Material Utilization: Intelligent cable routing algorithms reduce end-of-line scrap to 0.8% (industry average ≥3%)

Green Manufacturing: Oil-free design (dry stranding) prevents insulation contamination

Energy Recycling: Braking energy is fed back into the power grid, reducing carbon emissions by 12 tons per unit annually. This technology approach directly aligns with Gemwell's corporate responsibility framework, "Building a Sustainable World."

Q7: In what directions will stranding technology evolve in the future?

A: Based on Gemwell Electric Technology's R&D roadmap:

Superconducting Applications: Development of a low-temperature stranding platform operating in a -196°C liquid nitrogen environment

Heterogeneous Material Integration: Synchronous stranding and annealing of copper-aluminum composite conductors

Quantum Communication Cables: Submicron-level lay length control technology (accuracy ±0.05mm). These cutting-edge initiatives will continue to propel Gemwell towards its strategic positioning as a "technology solutions leader."