Product Category

Product Category

Covering the surface of wire and cable with strip materials is one of the important processes in wire production line, which has the functions of isolation, shielding, insulation, fire resistance, and temperature resistance. The wrapping methods include spiral wrapping, dragging (side) wrapping and longitudinal wrapping.

Spiral wrapping means that the core wire does not rotate while the spinning and taping head rotate concentrically around the core wire. The strip material is spirally wrapped around the core wire through the circular rotating motion of the taping head and the linear traction motion of the capstan. The wrapping angle is generally around 30-60 degrees, and the overlapping ratio can be adjusted within the range of 0-80%.

Drag (side) wrapping refers to the rotation of the core wire. The strip material is dragged in (rolled in) from the side with the rotating core wire. The wrapping angle is generally around 30-60 degrees, and the overlapping ratio can only be achieved by replacing strip materials of different widths.

Longitudinal wrapping means that neither the core wire nor the strip material rotates. The core wire and strip materials are linearly dragged by capstan at the same time, and gradually transforms the strip material into a forming package through the longitudinal wrapping mold. The wrapping angle is 90 degrees, and the overlapping ratio (generally around 5-10%) is achieved by replacing strip materials of different widths.

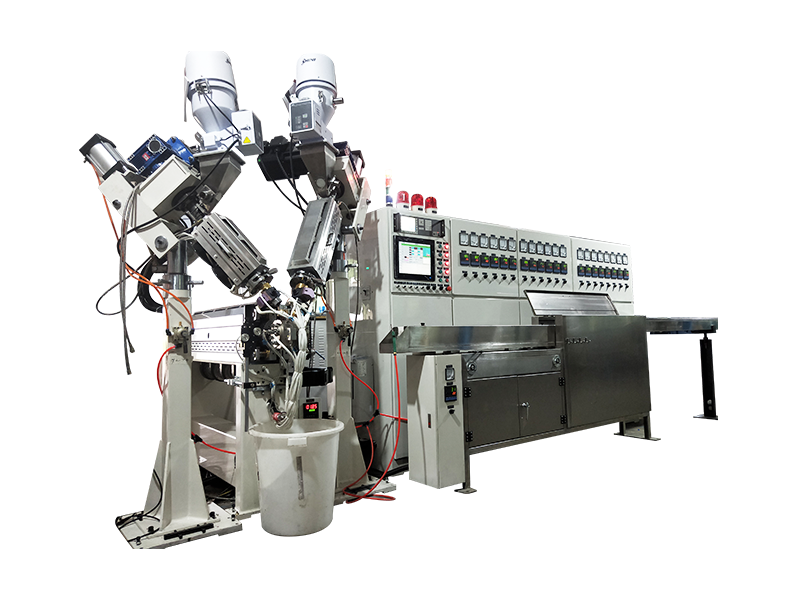

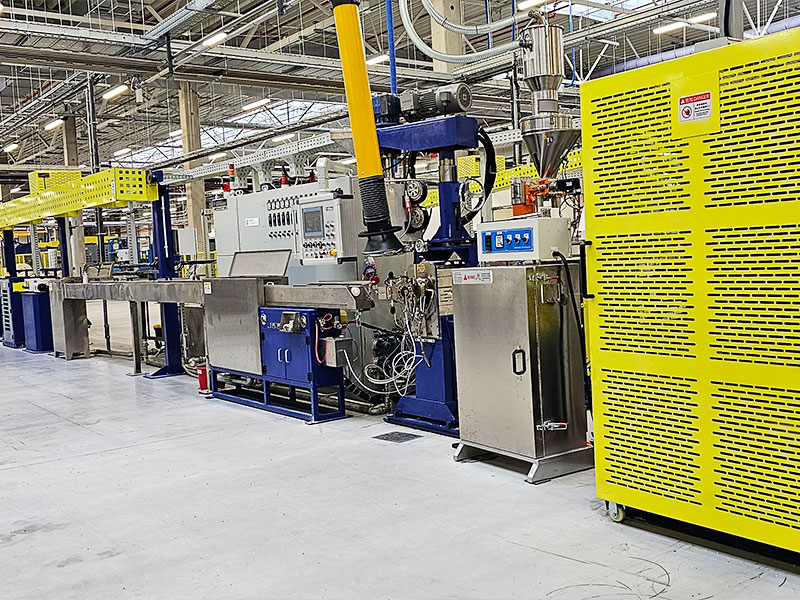

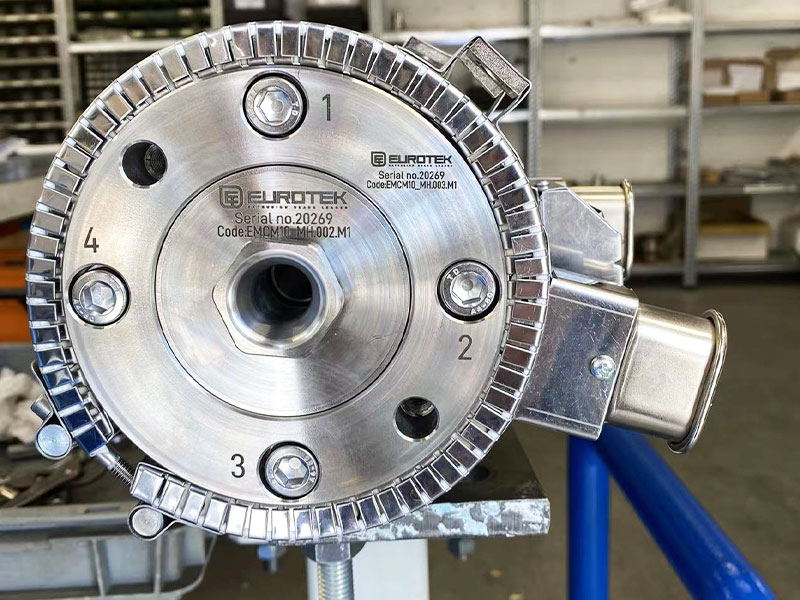

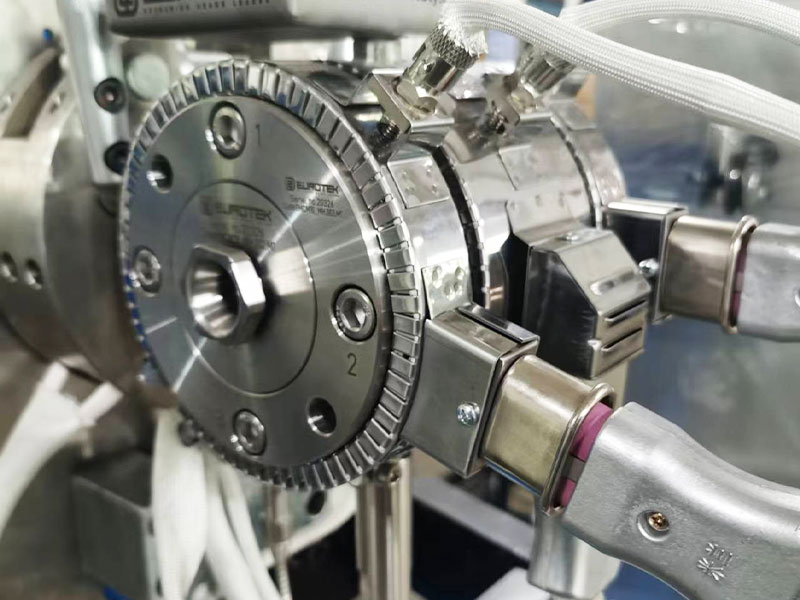

Commonly used taping materials include Aluminum Foil tape, Mylar tape, Copper Foil tape, Polytetrafluoroethylene tape, Mica tape, Polyimide tape, Polyester tape, etc. A general wire tape wrapping production line mainly consists of pay-off, taping head, capstan, and take-up. There are some auxiliary equipments added involved in the above process depending on the type of taping materials and detailed specifications for finished wire. The wire taping machine is available for vertical or horizontal structure. The vertical structure is suitable for small-sized cables, and the horizontal wrapping machine is more compactable with both large and small cables.

The wrapping methods include gap wrapping, butt-seam wrapping, and overlapping wrapping. Gap wrapping means that there is a certain gap between the previous and the next spiral tape edge. Butt-seam wrapping means that the edges of adjacent spiral wrapping tape are closely connected to each other. Overlapping wrapping means that when strip materials are wrapped, the previous spiral strip edge is covered by the next one. Overlapping wrapping is the commonly used method for wire and cable industry. Generally, the overlapping ratio is greater than 67% for single-layer wrapping and greater than 40% for double-layer wrapping. When double-layer or multi-layer is used, the wrapping directions should be opposite for each adjacent layer.

The wrapping process technical parameters include taping direction, pitch, angle, capstan speed, taping head rotation speed, taping tension, etc. The taping pitch refers to the distance that the wire core advances in the axial direction after one rotation by the wrapping head. The rotation speed of the wrapping process refers to the rotation speed of the taping head. The taping angle refers to the angle between the perpendicular axis of the wire movement line and the wrapping tape from taping head. The taping tension refers to the tensile force exerted at the taping point on the wrapping tape that passing through the guide wheel. The taping direction, pitch, tension, and finished outer diameter are the main parameters during the wire wrapping process, and the taping angle is the main parameter for taping machine design and manufaction. The thickness and overlapping ratio of the tape are determined based on the outer diameter of the wire core and finished wire. The width of the tape can also be determined based on the conductor outer diameter, overlapping ratio and taping angle. With a known tape width, a proper taping pitch can be selected to meet up with the overlap requirements.

The stability of the wrapping tension determines the quality and performance of the finished product. Uneven wrapping tension or unreasonable wrapping tension settings will cause defects such as uneven color, wrinkles, and “snakes” on the surface of the wire. The setting of the taping tension depends on the tensile strength of the wrapping material and the tension of the wire core. The material type, width and thickness of the wrapping material determine its tensile strength. Therefore, for different wrapping material or wire core specifications, the settings of taping tension differ.

The taping tension includes passive electromagnetic tension type and active servo tension type. The passive type uses magnetic powder clutch or hysteresis clutch as the tension element, which tracks the consumption of the outer diameter of the tap material pad or bobbin through meter or rotation counting. The electrical control system simulates the current output tension of the tension element to decrease. With this tension control method, tension is relatively stable and can basically meet the requirements of ordinary wire wrapping production in the cable industry. It has a simple structure with an economical and affordable price. The active type is divided into three-servo dancer type and capstan roller spit type. The main feature of three-servo dancer type is its tension dancer. The servo motor provides motion and tension to the tension dancer, and generates PID dynamic feedback to keep tap pay-off at a constant speed. Tension remains constant during the taping process, and it is not affected by the consumption of the outer diameter of the material tray. The capstan roller spit type doest not have a tension dancer. After the strip material is pulled out from the material tray through capstan wheel, it is immediately wrapped around the wire core. Taping tension is set according to the desired outer diameter of the finished wire. The outer diameter of the finished wire is set as a constant in the control panel, therefore, the taping tension remains constant for the whole procedure. The mechanical structures of these two active type taping machines are distinct, but both types are of great qualities. Due to the complex mechanical structure, advanced control system hardware and software configuration, the active type taping machine has a high production cost. But it can meet the stringent wrapping quality requirements in the wire and cable industry, with an effective rate close to and high cost performance. It is especially suitable for wire and cable products that require comprehensive electrical testing.

With the advancement of science and technology, taping machines must progress in the direction of high performance, high efficiency, high reliability, and high intelligence. As a explorer of new technologies of wrapping strip materials in the global wire and cable field, Gemwell Technology still focus on technology innovation and advancement. Gemwell Technology will create more high-quality Wire Taping Machine for you.

Establishment time

Building area (m²)

Number of employees

Intellectual property

A Mature Factory You Can Count On

A Mature Factory You Can Count On

2026-02-02

2026-02-02

Webmaster

Webmaster

A fish tape is like a "super pathfinder" in an electrician's hands. When you need to run electrical wires through long walls, conduits, or ceilings, y

Read More +

2026-01-26

2026-01-26

Webmaster

Webmaster

Although electrical tape can be a lifesaver in emergencies, using it for long-term repairs of damaged wires actually poses several safety hazards.Comp

Read More +

2026-01-19

2026-01-19

Webmaster

Webmaster

The Service Entrance Cable is the "bridge" connecting the main power grid to your home.If you imagine the city's power grid as the main pipes of a wat

Read More +

2026-01-12

2026-01-12

Webmaster

Webmaster

Replacing the cables on a wire and cable extruder is a maintenance task that requires care and patience. Here, "cables" typically refers to the power

Read More +

2026-01-05

2026-01-05

Webmaster

Webmaster

In the wire and cable industry, there are numerous manufacturers of wire and cable extruders. Based on the size of the manufacturers, their technologi

Read More +

Q1: What is the basic working principle of a wire taping machine? How does it improve efficiency in industrial applications?

A1: The core of a wire taping machine is to automatically and precisely wrap insulating tape (such as PVC or polyester tape) around wires or cables to enhance electrical insulation and mechanical protection. Its operation relies on a synchronous control system, where the wire feed mechanism precisely controls the wire feed speed, while the tape winding mechanism uses a servo motor to adjust the tension to ensure uniform tape winding. In practice at Gemwell Electrical Technology (Jiangsu) Co., Ltd., this machine has improved production efficiency by 20%-30% by optimizing speed and tension parameters, particularly in high-frequency applications such as automotive wiring harnesses and home appliance cable production, eliminating manual errors and waste. Gemwell emphasizes that through discussions with customer needs, the equipment size can be customized to meet production line throughput. For example, a small machine is suitable for small-batch custom cables, while a large machine is designed for large-scale industrial applications, enabling unmanned, continuous operation.

Q2: Why is the requirements analysis phase so critical when designing and deploying a wire tapping machine? How does Gemwell ensure equipment performance through this process? A2: Requirements analysis is fundamental, as the performance of a wire tapping machine depends directly on a deep understanding of the customer's specific scenario. This phase includes evaluating the cable equipment type (e.g., single-core or multi-core), production scale (e.g., thousands or tens of thousands of meters per day), process flow (e.g., pre-taping or post-process integration), and target production efficiency (e.g., the number of wires taped per minute). Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) conducts multiple technical dialogues with customers at the start of a project, focusing on these key dimensions. For example, they discuss whether cable diameter range affects taping accuracy or how production efficiency targets drive machine selection. This detailed analysis enables Gemwell to identify potential bottlenecks, such as the need for enhanced moisture-proofing in high-humidity environments. This ensures stable operation in real-world applications, reduces failure rates, and extends machine life.

Q3: Based on the results of the requirements analysis, what key technical decisions are involved in the system design phase? What are Gemwell's unique advantages in automation and control?

A3: The core of the system design phase is integrating advanced technologies to achieve efficient and reliable operation. This includes selecting the appropriate automation control system (such as a PLC or motion controller), sensor type (such as photoelectric or encoder), and actuator (such as a servo drive). Workflow design requires optimized path logic, such as synchronizing the timing of wire feeding and tape winding to avoid material stretching or breakage. For data communication, industrial Ethernet or Modbus protocols are used to enable real-time data exchange between the machine and a higher-level system (such as an MES) to monitor parameters such as tension deviation and production statistics. Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) emphasizes modular design in this regard: By analyzing customer needs, they may choose a high-performance servo system to match high-precision tape winding tasks or integrate predictive maintenance algorithms to reduce downtime. In system integration, Gemwell focuses on compatibility, ensuring the machine seamlessly integrates into the production line and improving overall OEE (Overall Equipment Effectiveness).

Q4: How does the process flow of a wire tapping machine affect the quality of the final product? How does Gemwell improve reliability and consistency through process optimization?

A4: The process flow is a key factor in determining wire insulation quality, including tape pre-assembly, tension control, winding angle calibration, and end treatment. Any deviation, such as uneven tension, can cause the tape to loosen or overlap, potentially leading to electrical short circuit risks. Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) carefully evaluates customer product specifications during demand discussions. For example, thin-walled cables require low tension settings to prevent deformation, while high-temperature applications require heat-resistant tape. Through system design, Gemwell incorporates a closed-loop feedback mechanism: real-time monitoring of tension sensor data automatically adjusts servo motor speed to ensure winding uniformity within ±0.1mm. Furthermore, production efficiency is optimized through streamlined processes, such as the integration of an automatic tape change system, which reduces manual intervention and enables the machine to maintain over 99% product consistency in 24/7 operation, significantly reducing rework rates.

Q5: Why are data communication and system integration crucial for wire tapping machines in modern production lines? How does Gemwell demonstrate this advantage in specific practices?

A5: Data communication and system integration are at the core of intelligent manufacturing. They ensure that machines can adapt to environmental changes and collaborate with the entire production line. For example, using Industrial Internet of Things (IIoT) protocols, wire tapping machines can upload real-time operating data (such as energy consumption or fault codes), supporting remote diagnostics and preventive maintenance. System integration involves linking with upstream (such as extruders) and downstream (such as testing equipment) to enable data sharing (such as wire size information) and avoid production gaps. Gemwell Electric Technology (Jiangsu) Co., Ltd. (Gemwell) designs customized integration solutions based on the customer's scale. For large-scale plants, OPC UA is used to enable cross-system communication and improve data transparency; for smaller applications, interfaces are simplified to reduce costs. Gemwell's experience has shown that this integration can increase machine efficiency by 15%. Data analysis can also optimize maintenance plans, such as predicting strip depletion time and reducing unplanned downtime.

Q6: Facing diverse industry needs, what are Gemwell's key innovation priorities for wire tapping machines? How do these address real-world user challenges?

A6: Innovation focuses on adaptability and sustainability to address customer pain points in efficiency, cost, and compliance. Gemwell Electrical Technology (Jiangsu) Co., Ltd. (Gemwell) identified trends such as green manufacturing through demand analysis, driving the development of energy-saving drive systems (such as variable frequency control) and reducing energy consumption by 30%. Furthermore, to address process complexity, they strengthened modular design, allowing for rapid component replacement (such as coils of varying strip widths) and enhancing equipment flexibility. In system integration, Gemwell prioritizes AI-assisted decision-making (while avoiding over-automation), such as optimizing winding parameters based on historical data to address batch size fluctuations. These initiatives, informed by in-depth customer conversations, ensure that Gemwell's machines are not only technologically advanced but also directly address real-world problems, such as reducing raw material waste and shortening model changeover time, ultimately supporting users in achieving lean production goals.